SAILFISH 276 DC | ALUMINUM COSMETIC CORROSION (PITTING)

The information provided is designed

to give you a thorough understanding

of the factors that can impact the ap-

pearance of your anodized aluminum.

By using this information, we hope to

help you enhance the beauty and value

of our products.

What Causes It?

Corrosion is a natural phenomenon

that affects metals by either a

chemical or electrochemical reaction.

The rate at which aluminum corrodes

depends greatly on the environmental

conditions and the amount of pre-

ventative maintenance performed.

Our goal is to slow down or stop this

natural phenomenon we call pitting (or

corrosion).

Anodized Aluminum

The aluminum on your boat has been

anodized. This creates a very hard

protective seal on the surface of

the aluminum to protect it as much

as possible from pitting. When the

anodized coating is broken and raw

aluminum is exposed, corrosion will

take place. Damage from other abra-

sive impacts can break the anodized

coating.

Chemical Attack

Corrosive chemicals containing high

concentrations of acids or alkalis

will remove the anodized coating.

Solutions containing chlorine, salts,

or ammonia are all harmful to the

anodized aluminum on your boat.

Many common household cleaners

contain chemicals that will remove the

anodizing and cause pitting.

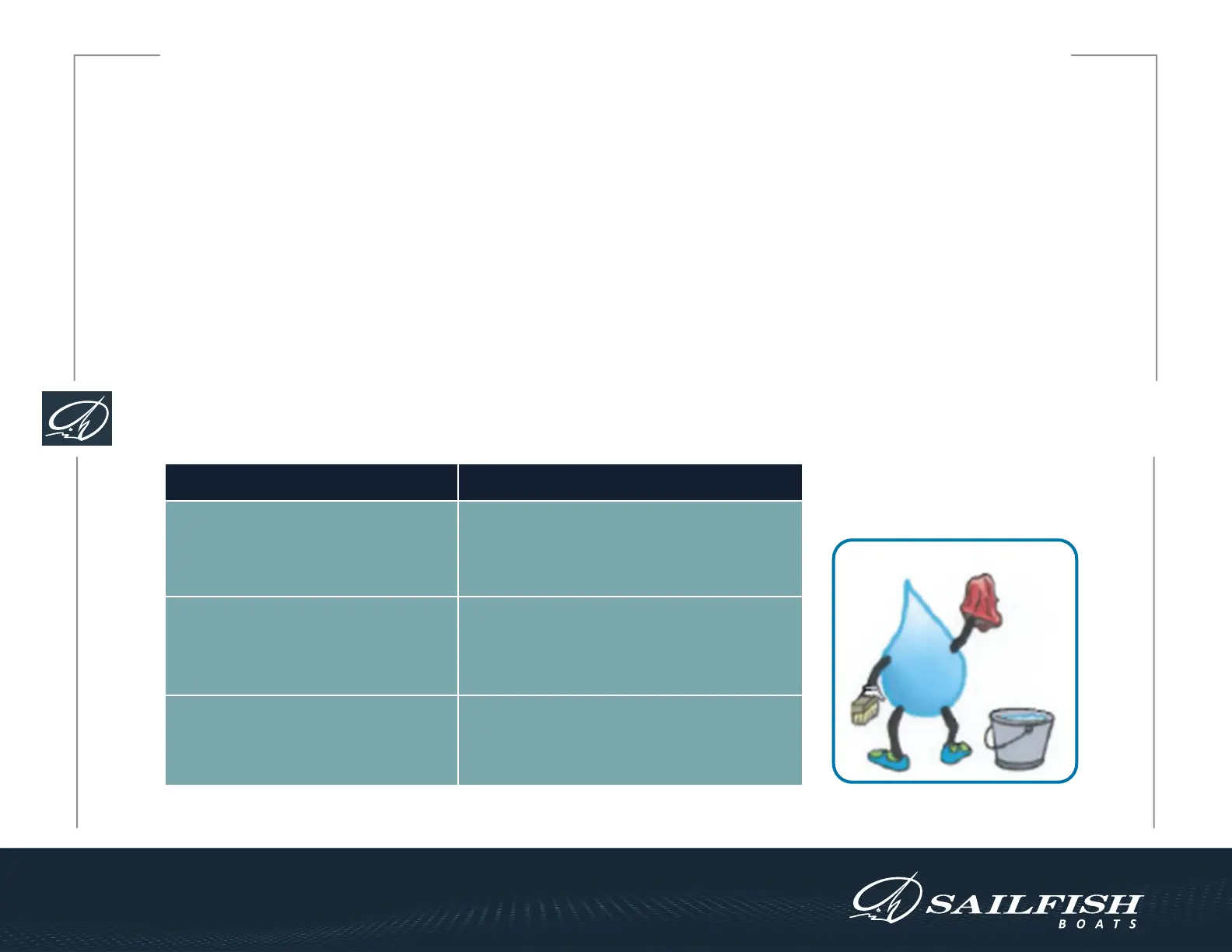

AVOIDABLE UNAVOIDABLE

Strong acidic solutions found in

cleaners, paint remover, degreasers,

etc.

Airborne pollution. Airborne particles from

local sources: vehicles, incinerators, paper

mills, chemical plants, power plants, etc.

Concentrated alkaline based solu-

tions. Many concentrated soaps fall

into this category.

Harsh chemicals from work performed at

local shipyards and dry docks.

Chlorine, sulfurs, solvents and am-

monia based products.

Be aware of local sources that can expose

your new boat to corrosive chemicals.

57

Loading...

Loading...