Tissue-Tek® Glas™ Coverslipper

Quick Reference Guide

Tissue-Tek® Glas™ Coverslipper

page 4 | 6 QRG | Glas Coverslipper | 2011 | V-2

Preparation before coverslipping

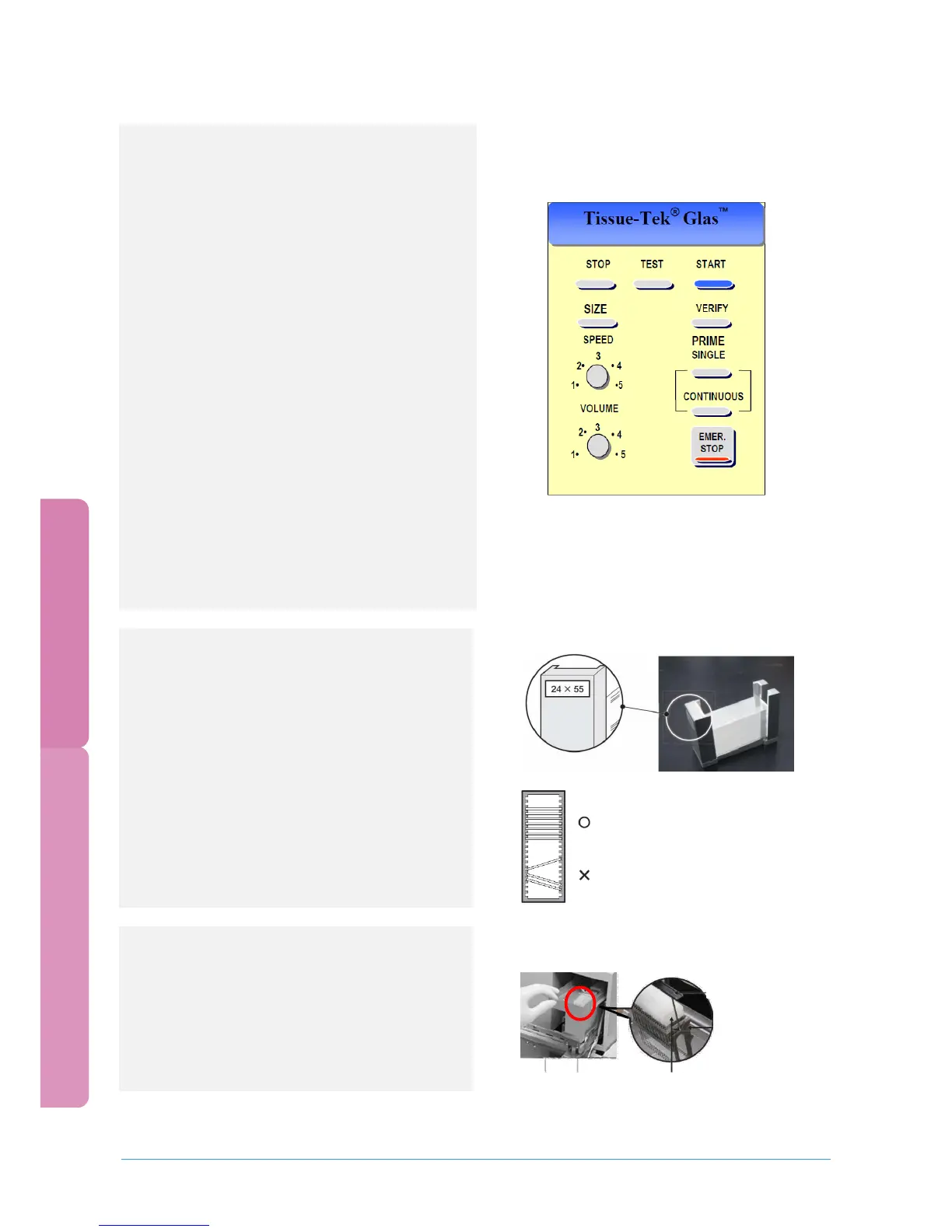

Software

VOLUME KNOB

Can be used to fine tune the volume of mounting

medium dispensed on the slide.

SPEED KNOB

Refers to the speed at which the coverglass is

applied to the slide.

STOP

Can be used to stop the instrument while operating.

TEST

Can be beneficial if the operator would like to test

one slide.

SIZE

Toggles between coverglass sizes 40, 50, 55 and 60

mm.

VERIFY

Key acts as an enter key.

PRIMING FUNCTION

Can be used to verify proper dispensing.

When “single key” is pressed mounting medium

will be dispensed from the nozzle one time.

When “continuous” key is pressed the mounting

medium will dispensed continuously until the

“STOP” key is pressed.

Coverslipping Operation

Cover slipping slides

Pre-operational checks

1. Turn on POWER.

2. Remove the loading station lid.

3. Check the solvent volume level in anti-drying

bottle and dispensing pump reservoir.

4. Clean any possibly spilled mounting medium.

5. Place receiving racks in the unloading area.

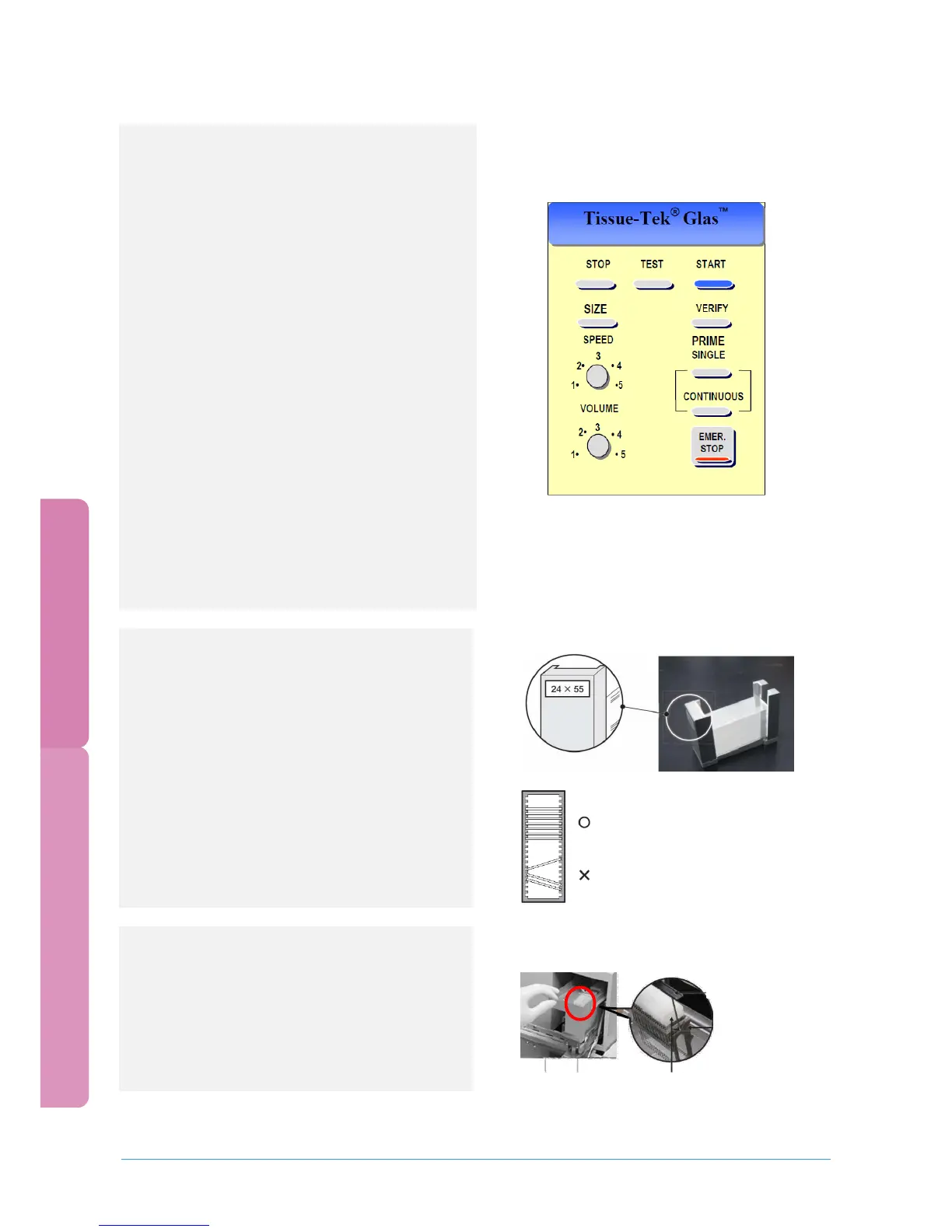

6. Put coverglass (CG) holders in place and fill

with coverglasses.

7. Check if CG size on screen matches CG in

holder.

8. Check the volume level of mounting medium.

Start of operation

1. Check CG size, coverslipping speed and volume

of mounting medium.

2. Select coverslipping program.

3. Press and hold [prime] key for 3 seconds

4. Pull out the loading station and set baskets.

Close loading station door and [start]

coverslipping.

Insert slides in parallel

Loading...

Loading...