15

Competence in Functional Safety

Functional safety of globe valves, rotary plug valves, ball valves and butterfly valves

5.3 Ball valve requirements Responsibility

Note for ball valves that higher initial breakaway torques arise as the differential pressure

of the process medium rises, requiring higher actuator torques.

Manufacturer

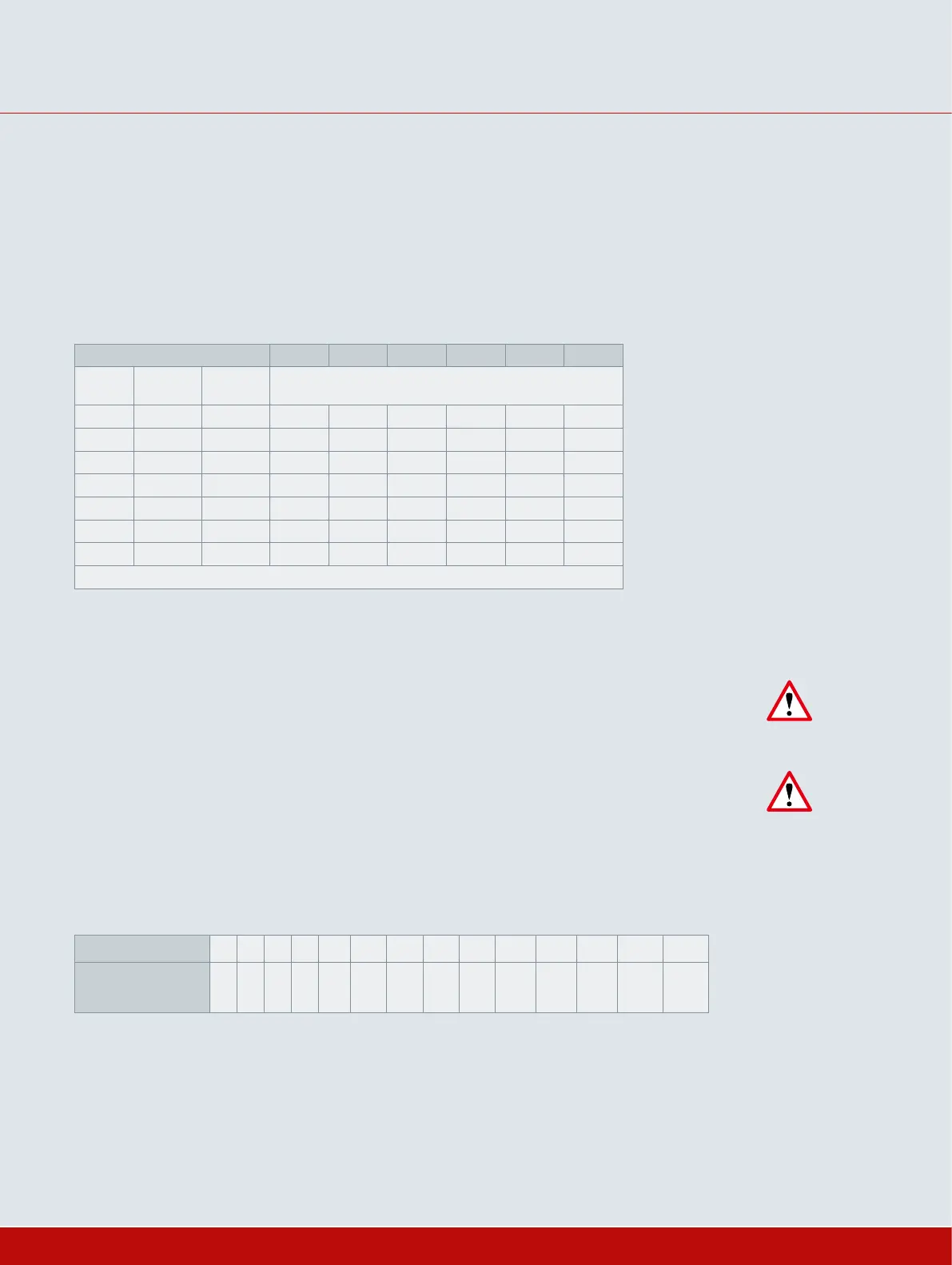

Differential pressure ∆p (bar) 0 3 6 10 16 40

DN

M

dmax

(Nm)

M

d

(Nm) M

dl

(Nm)

15 60 3 5 5 5 8 9 11

25 240 5 10 10 10 14 18 28

40 450 10 20 20 20 26 35 52

50 450 15 30 30 33 36 42 73

80 750 25 60 60 66 72 86 144

100 750 40 90 90 105 120 140 251

150 3160 60 120 120 160 210 290 450

Max. permissible torque, required torques and initial breakaway torques

Example: Torque specifications for a ball valve

Media, especially degreasing, swelling and fibrous media, may affect the torque.

The operating conditions, e.g. switching interval and the medium temperature, have

an effect on the torques.

The mounting of the valve and actuator is of vital importance.

The permissible torques for the ball valve shaft, shaft adapter and bridge have been

verified by the manufacturer. As a result, the max. torque of the actuator (air or spring

torque) must not exceed these torques under any circumstances.

The corresponding specifications in accordance with DIN EN ISO 5211/DIN EN 15081

(NAMUR Recommendation NE 14) must be observed

Operator

Manufacturer

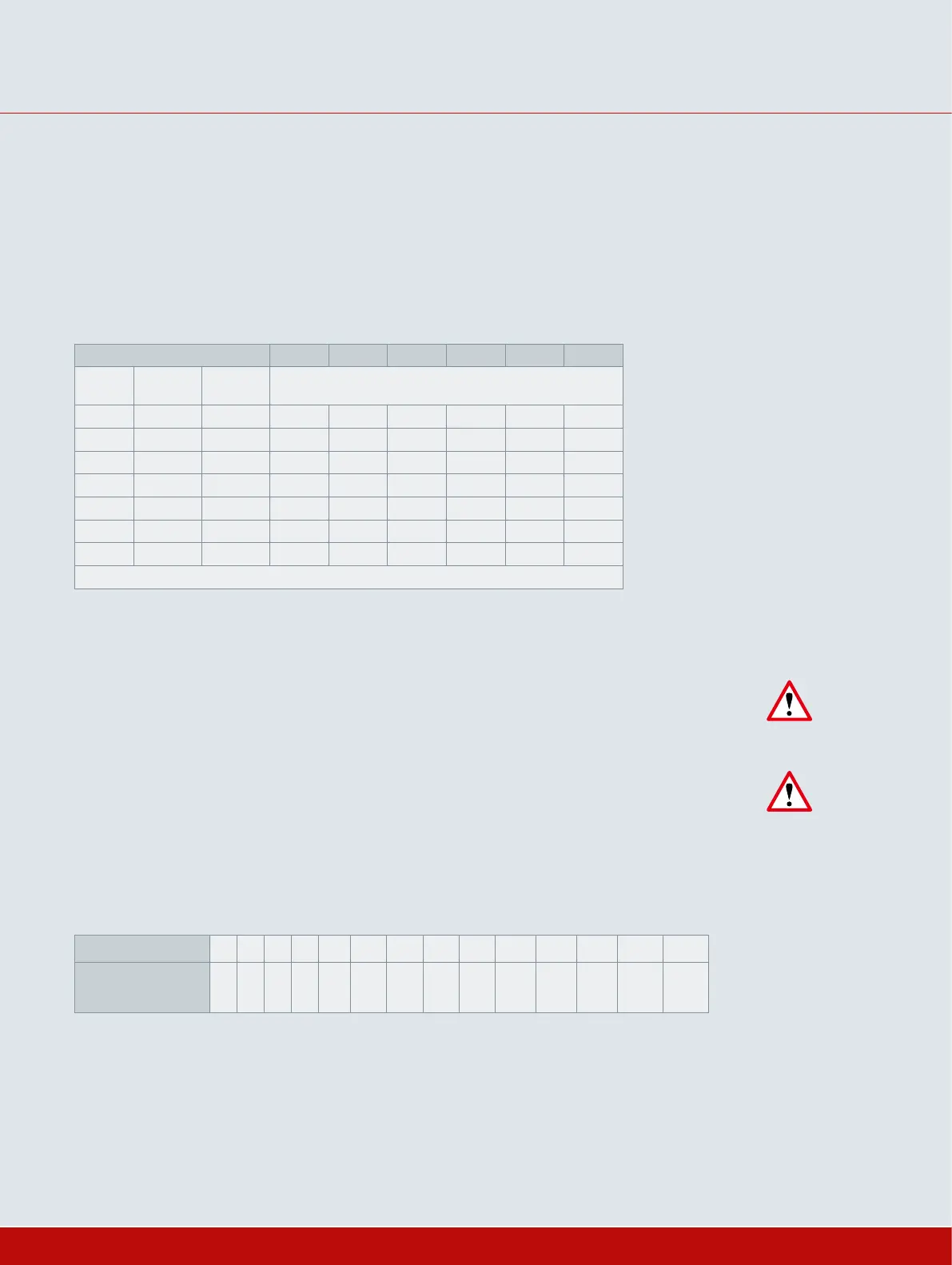

Flange type

F03 F04 F05 F07 F10 F12 F14 F16 F25 F30 F35 F40 F48 F60

Maximum torque of the

attachment flanges (Nm)

32 63 125 250 500 1000 2000 4000 8000 16000 32000 63000 125000 250000

Maximum torque of the attachment flanges according to DIN EN ISO 5211

Loading...

Loading...