10

8. TROUBLE ANALYSIS & SHOOTING

*Refer to the trouble analysis section of user s manual for non-faultreason.

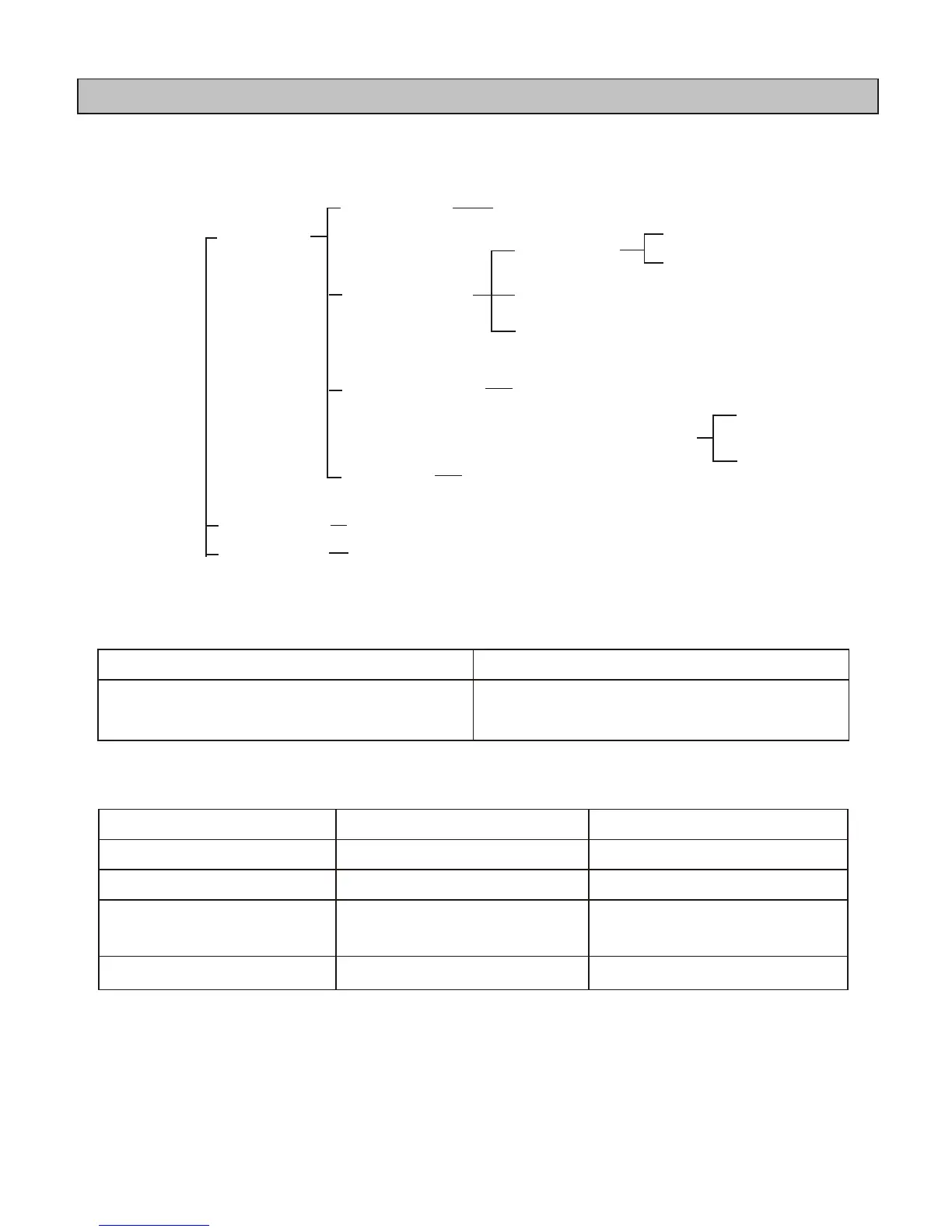

Table 1: check and root out cooling system troubles

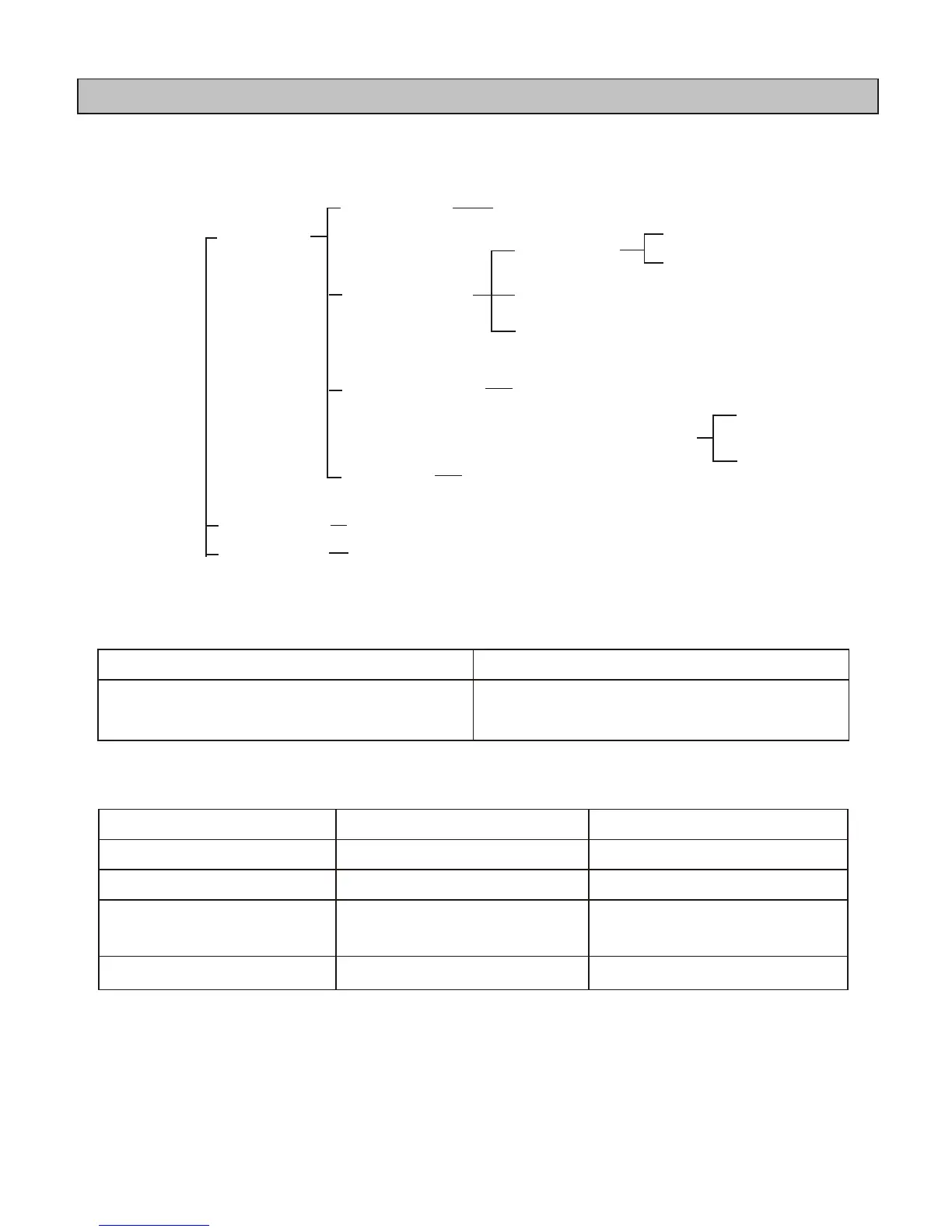

Table 2: circuit checksheet for irregular run

Drop a dirb of water on the evaporator to

see if it is iced after 20 minutes run.

Check the leaking place and add

refrigerant after vacuumizing.

Check

Item

Startup voltage

When other parts work well

Damaged motor and compressor

PTC. relay

Compressor motor (deputy

windings) conducting test

Broken wire Change compressor

Change compressor

Damaged Change relay

Too low voltage Voltage up (mount stablizer)

Reason Solution

Root out

`

`

Test on

compress

working status

Normal run

Run failure

Break down

No cooling

Temperature

setting

Too low (set higher)

Malfunctional sensor

Loose gasket (clean soils or change it)

Evap. frost (defrost)

Change PCB and

confirm single

Change E-

magnetic valve

Inferior cooling

Unable to

shut Ref

Fre cooling

No Ref cooling

(under the normal mode)

E-magnetic reversion

failure or control single

not found

E-magnetic reversion

failure or control single

not found

Check the cooling system (see figure1)

Check the electric circuit (see figure 2)

Check the electric circuit (see figure 3)

Loading...

Loading...