10

RUNNING-IN

Recommended running in period for a new machine is 50 000 crimps. It will be enough if the greasing cycle

is halved during the running in period. The purpose of frequent greasing is to ensure that there is always

grease enough between the sliding surfaces. Due to the surface pressure the grease sinks in to the metal

pores ensuring good sliding properties for the machine’s lifetime. During the running in period grease the

machine affter every 1000 crimps.

GREASING

The master dies of the machine has been greased at the factory after the final testing. However, the grease

may have dried during the transportation and storing and therefore the machine should be greased

according to the operating instructions before commissioning.

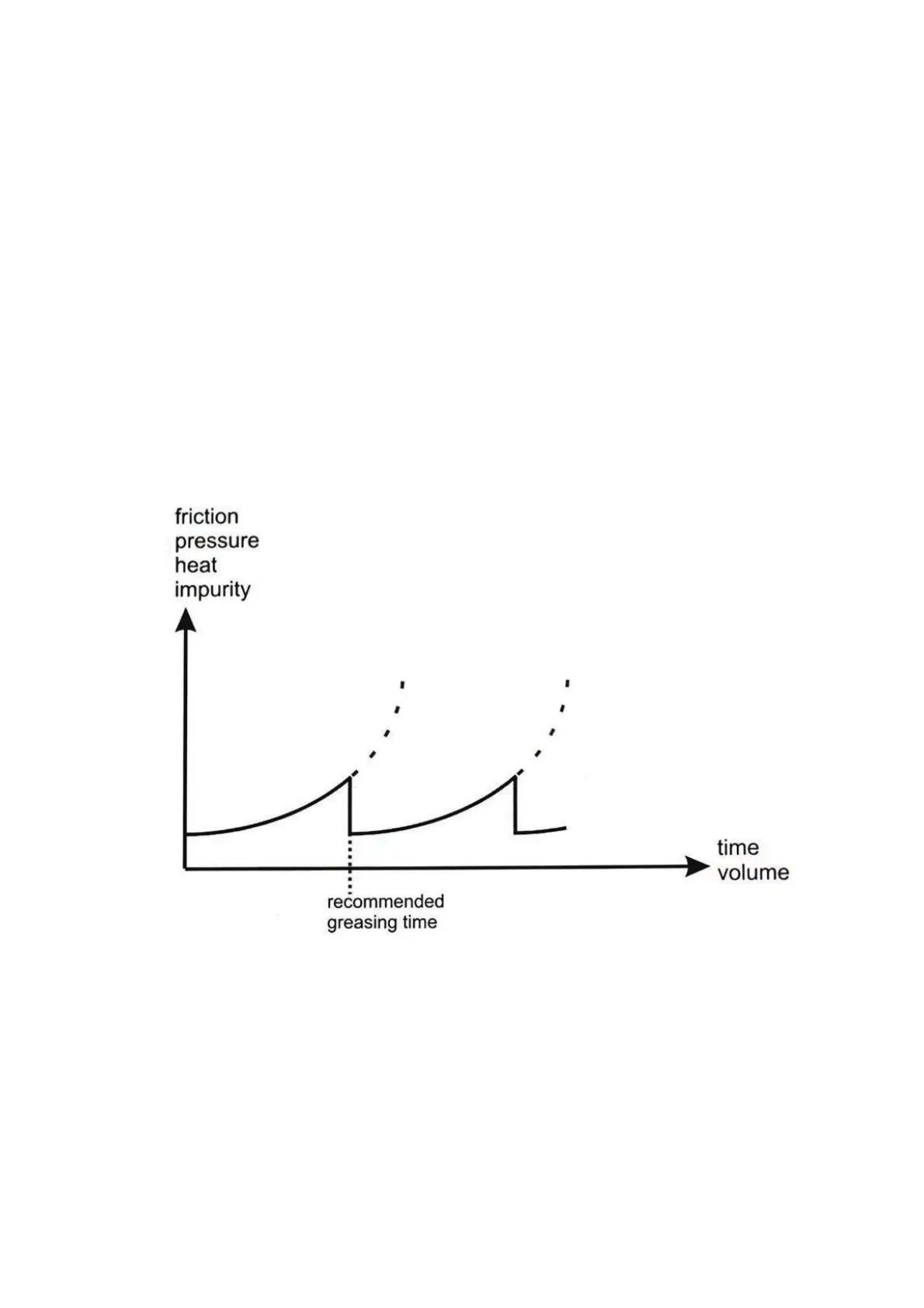

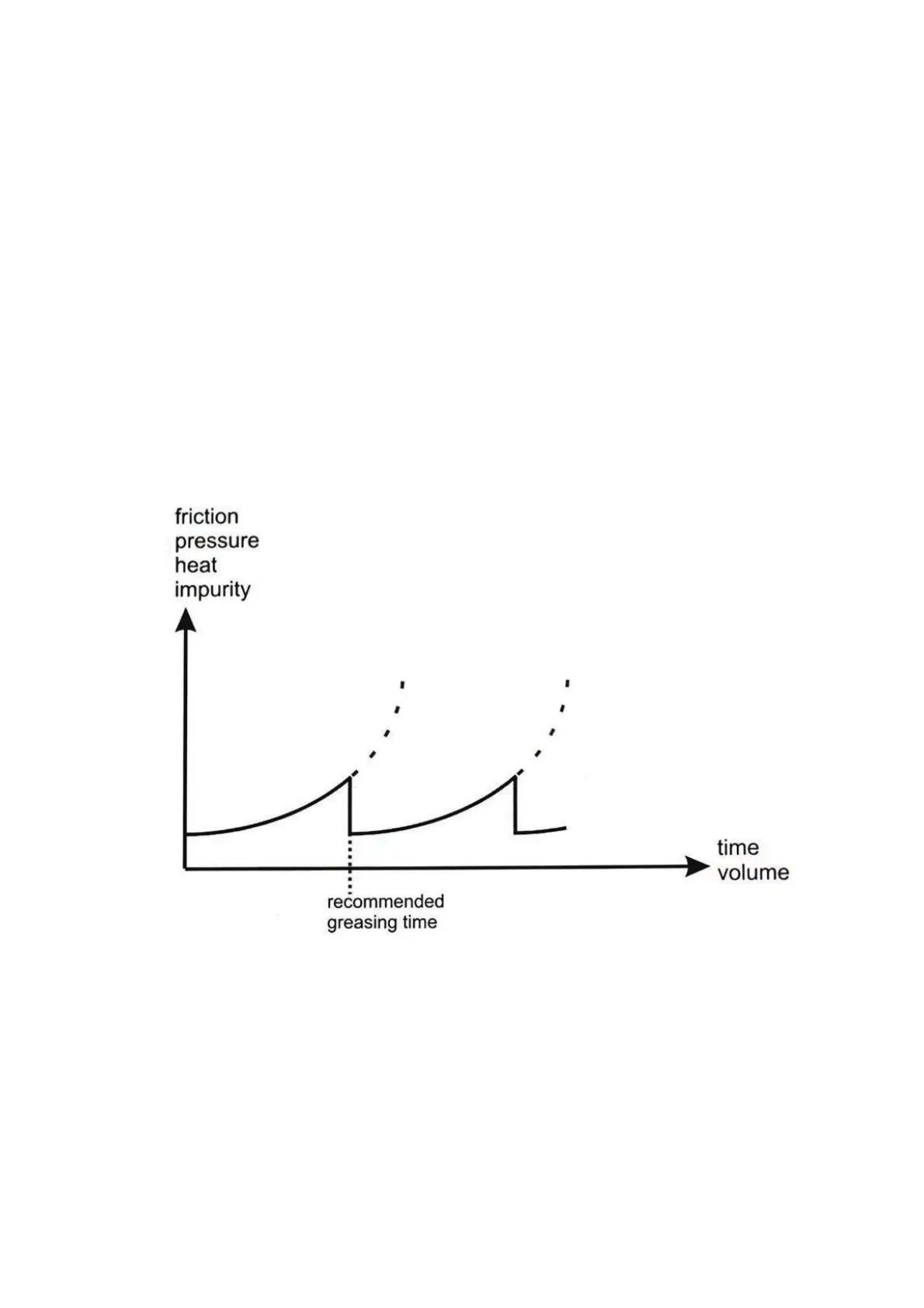

Greasing of the master dies is an important maintenance procedure which should be made regularly. The

adverse working environment and crimping volume have a special effect on the need for maintenance.

Preventive maintenance and proper use help to ensure trouble-free operation of the machine. It is

recommended to grease the machine after every 2000 crimps, except during the running in period when

the greasing should be done after every 1000 crimps.

QUICK FIX-PACKAGE

Included with the machine, there is a Quick Fix-package which has some basic parts for this machine

model.

Loading...

Loading...