S&C ELECTRIC COMPANY

s

INSTRUCTION SHEET

716-501

Page 21 of 26

August 12, 2002

INSTALLATION — Continued

(c) Pry the container-halves apart with a screwdriver. The

upper container-half can now be removed and dis-

carded—slotted holes are provided so that a rope or

lifting sling can be attached and the container-half

more conveniently lowered to the ground.

(d) Now remove and discard the ³⁄₈—16⁷⁄₈ hex-head

cap screw and flat washer which attach the lower con-

tainer-half to the coupling end casting of the inter-

rupter, and the ³⁄₈—16⁷⁄₈ hex-head cap screw and

flat washer which attach the lower container-half to

the indicator end casting of the interrupter. Then dis-

card this container-half.

(e) Finally, remove and discard the foam-core inner liner

wrapped around the interrupter.

Now remove the shield for the pressure-relief

device and low-gas-pressure indicator.

Step 25

Remove and discard the plastic bubble-wrap from each

insulating support column.

Step 26

Perform the following set-up procedure on the operator.

See Figure 15.

(a) To avoid accidentally energizing the operator after the

external connections have been completed, open the

control-source disconnect switch.

(b) Loosen the clamps on the inside of the side access

door, open the side access door, and remove the

blocking from the motor contactors.

(c) Mark the conduit-entrance location for the control-cir-

cuit wiring on the conduit entrance plate in the bottom

of the operator enclosure. Then remove the plate and

cut out the necessary opening. Apply the sealing com-

pound furnished, replace the plate, and make up the

entrance fittings. Verify that the entrance fittings are

properly sealed to prevent water ingress.

(d) Connect the external control-circuit wiring (including

the space-heater source leads) to the terminal blocks

at the bottom of the enclosure, in accordance with the

wiring diagram furnished. Observe correct polarity on

dc-control-voltage models. Trip-circuit conductors

and motor-and-closing circuit conductors must be

adequately sized for the ampacities indicated on the

wiring diagram.

Ç

CAUTION

Unauthorized changes should not be made in the

wiring of the operator. Should a control-circuit revi-

sion appear desirable, it should be made only on the

authority of a revised wiring diagram which has been

approved by both the user and S&C Electric Com-

pany.

Do not apply control voltage to the operator at this

time!

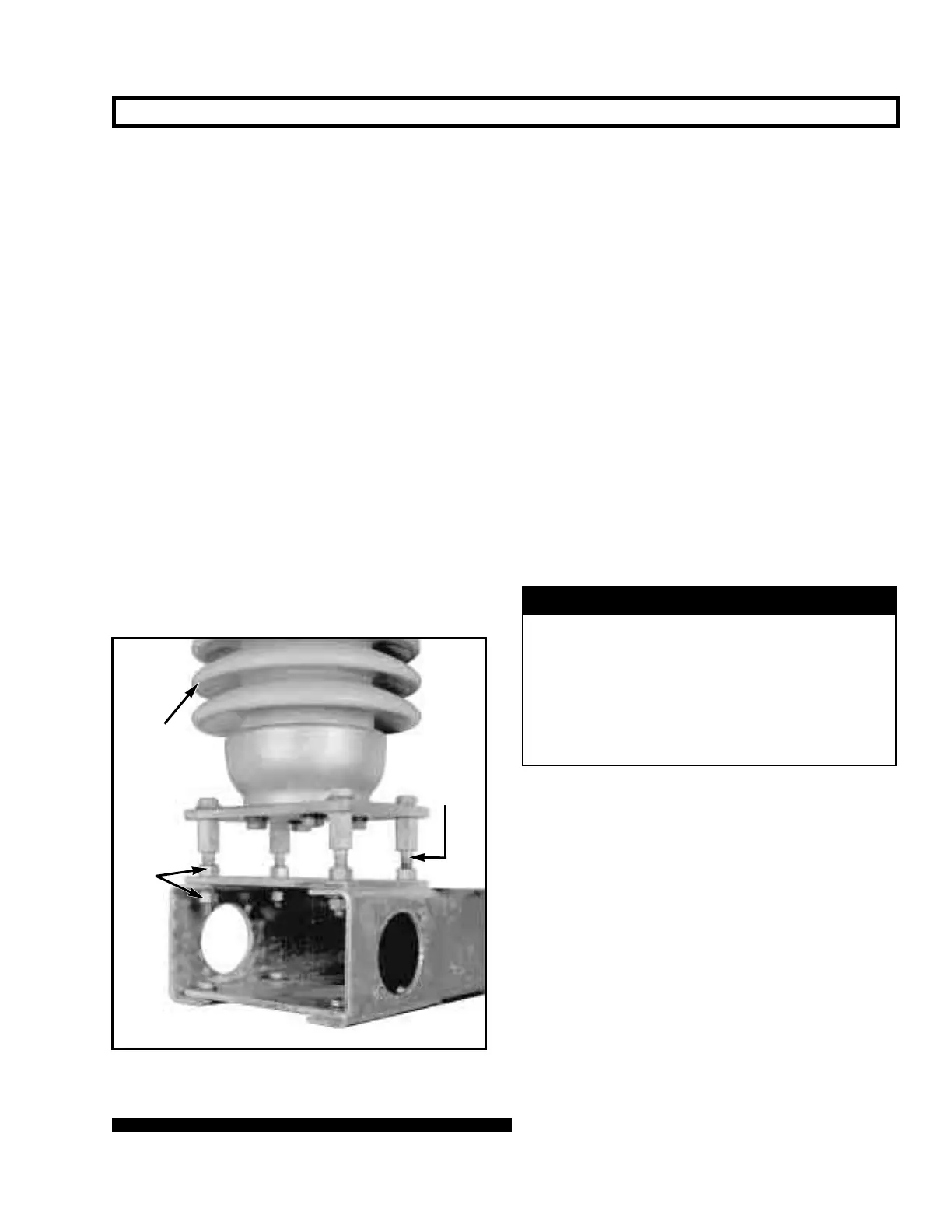

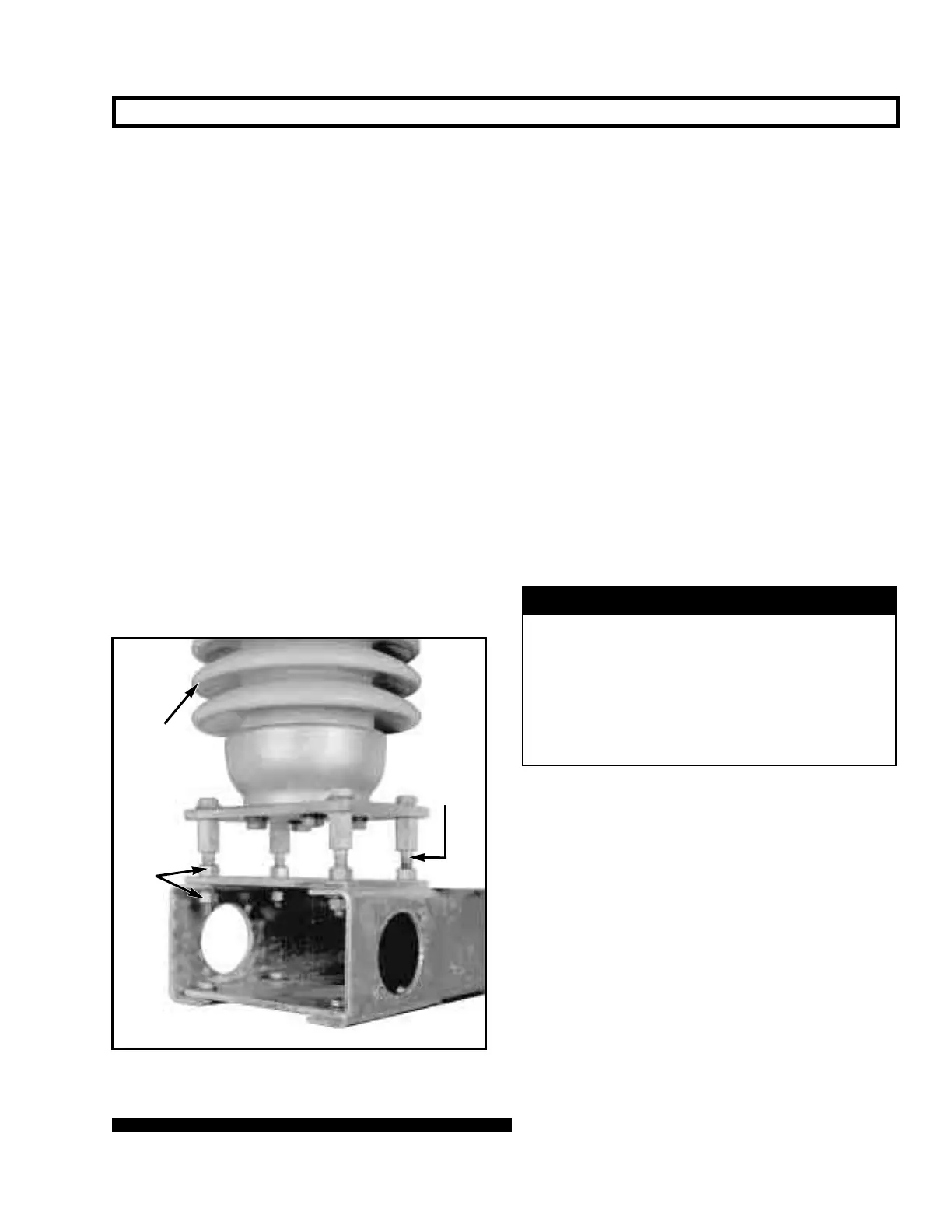

Figure 14. Adjusting leveling-screw locknuts.

Jaw-contact

support

insulator

Locknuts

Leveling

screw

Loading...

Loading...