Installation

S&C Instruction Sheet 716-500 19

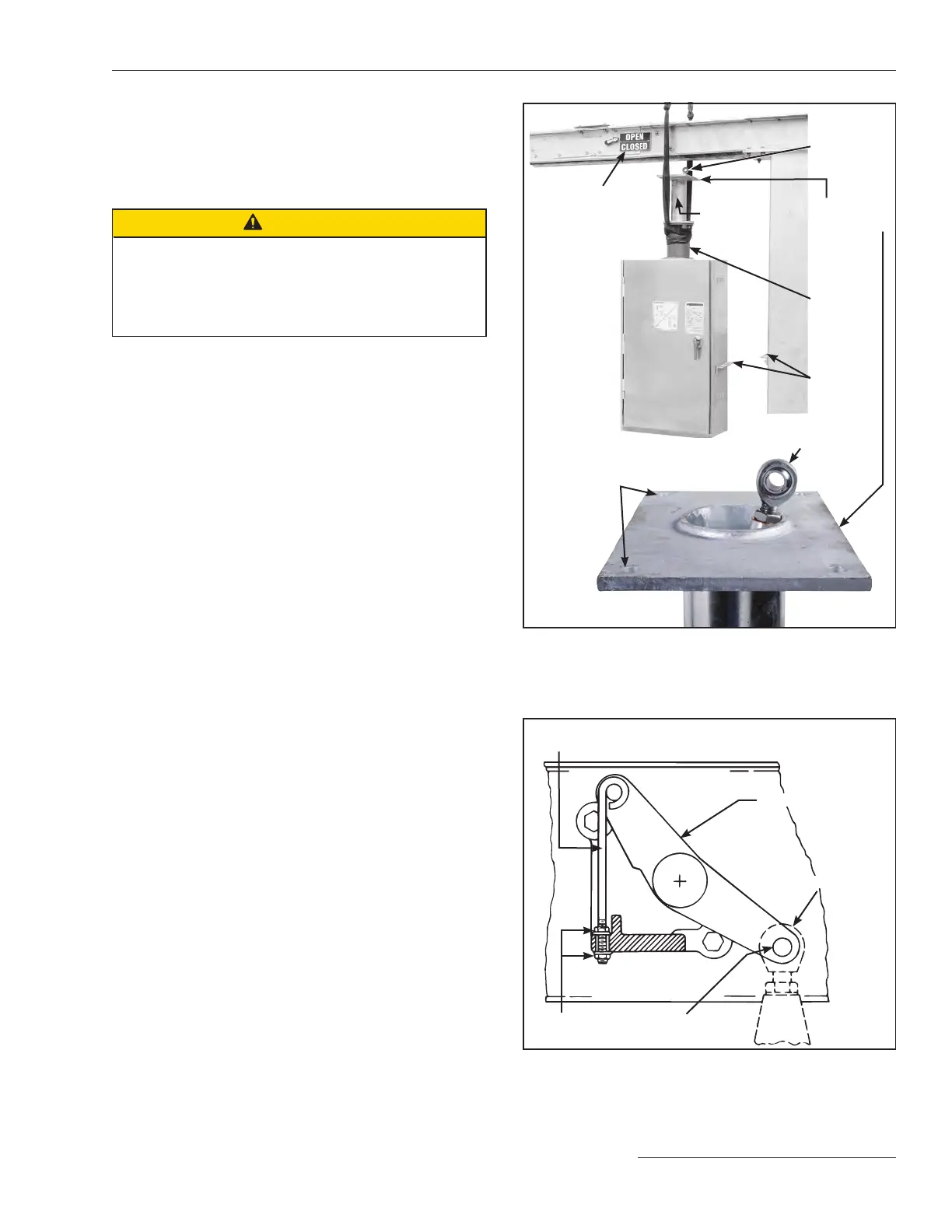

STEP 15. Reposition the lifting sling around the front of the

stored-energy housing and wrap another lifting

sling around the back of the stored-energy housing,

as shown in Figure 21. Face the operator door the

same direction as the Switch Position indicator on

the high-speed base. Hoist the operator into place.

CAUTION

Be careful not to damage the uni-ball coupling on the

operator-connecting link during hoisting and attachment

of the operator. The uni-ball coupling cannot be replaced

in the field. Damage will necessitate returning the opera-

tor for replacement.

Attach the operator support tube mounting plate to the

underside of the high-speed base using four ½-13 x 1¾ hex-

head galvanized steel cap screws, at washers, and self-

locking hex nuts. Lubricate the screws to facilitate tightening.

Tighten all four screws securely.

STEP 16. Attach the operator support angle to the appropri-

ate mounting pedestal using two ⅝-11 x 14 hex-head

galvanized steel cap screws, four at washers, and

two self-locking hex nuts. Refer to the catalog

drawing for exact placement. See Figure 21. Attach

the operator support plate to the angle on the

operator and the angle on the mounting pedestal

using four ½-13 x 1½ hex-head galvanized steel cap

screws, at washers, and self-locking nuts fur-

nished. Lubricate the bolts to facilitate tightening.

Securely tighten the screws. On circuit-switchers

with two or three mounting pedestals, insert the

hole plugs furnished into all unused holes in the

pedestals.

Uni-ball

coupling

Operator

support

tube

Stored-

energy

housing

Operator

support tube

mounting

plate

Holes (4) for ½ –132¾-inch hex-

head galvanized steel cap screws,

flat washers, and self-locking nuts

Uni-ball coupling

Operator

support

angles

Switch position

indicator

Figure 21. Hoist operator into position below the high-speed base

using a lifting crane.

Connecting the Operator to the High-Speed

Power Train

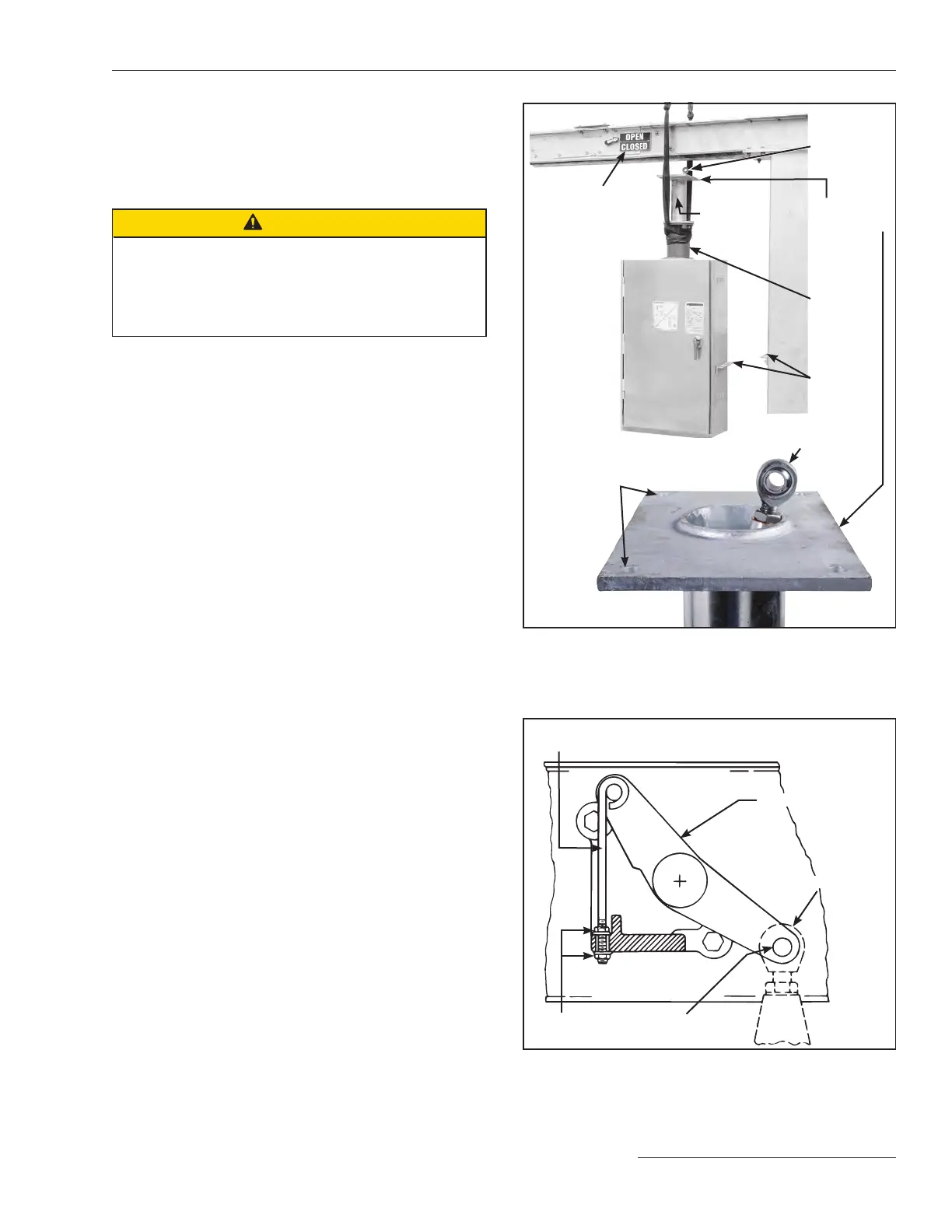

STEP 17. Attach the uni-ball coupling on the operator con-

necting link to the interphase drive lever in the

high-speed base using the ¾-inch stainless steel pin

and cotter pin retained from Step 7. See Figure 22.

An adjustable locking rod (marked with a black/

yellow striped label) is furnished, factory con-

nected to the interphase drive lever; turn the asso-

ciated ¼-20 locknuts as required to raise or lower

the interphase drive lever to facilitate insertion of

the stainless steel pin.

STEP 18. After the pin is installed, remove the lower ¼-20

locknut that retains the adjustable locking rod, and

then remove and discard the adjustable locking rod

and locknuts. See Figure 22.

Interphase drive lever

Adjustable locking rod (marked

with a black/yellow striped label)

¾-inch stainless steel

pin and cotter pin

Uni-ball coupling

¼-inch–20

locknut

Figure 22. Attach the uni-ball coupling on the operator-connecting

link to the interphase-drive lever inside the high-speed base.

Loading...

Loading...