Installation

26 S&C Instruction Sheet 716-500

(d) In the switch operator make sure:

• Correct polarity has been observed on dc-control-

voltage models (see Figure 29)

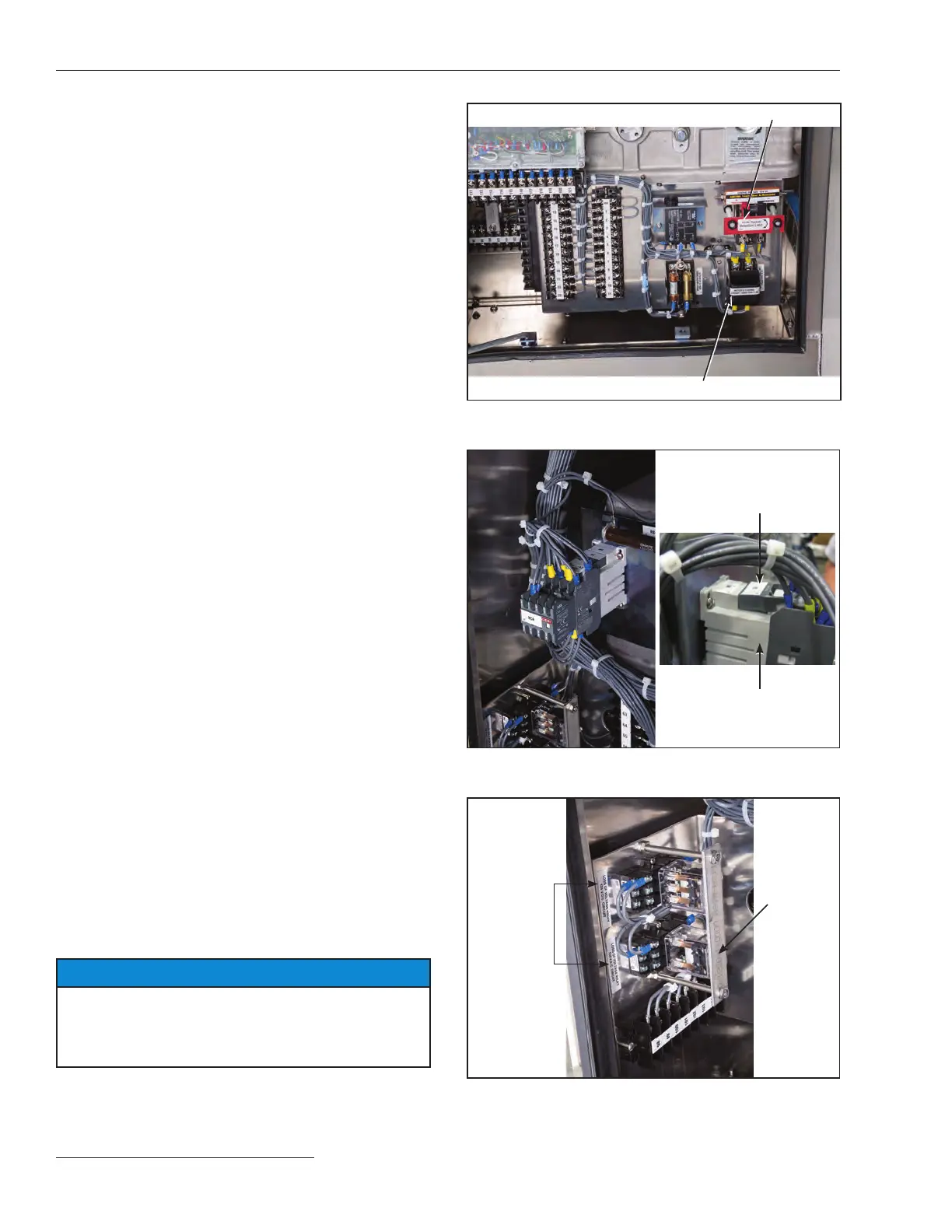

• To check the motor contactor and surge suppres-

sor to ensure all electrical connections are secure,

and that the surge suppressor is fully-seated in its

mount (see Figure 30)

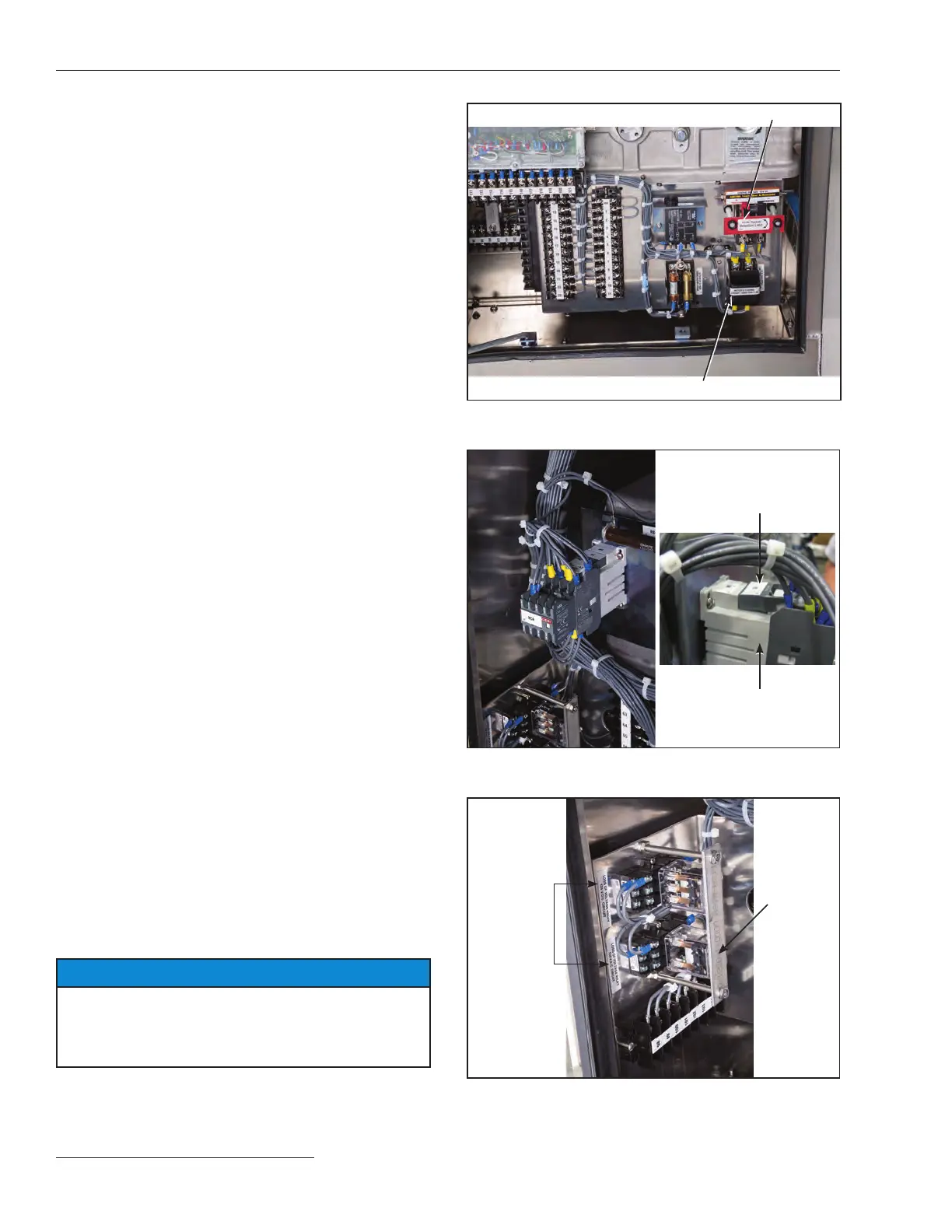

• Any optional “ice-cube” style relays (used for

catalog option “-P” and “-T2”) are fully seated in

their mounts (see Figure 31)

(e) Make sure all other pinned connections have been

made and all bolted connections have been securely

tightened.

STEP 24. Replace the access cover on the side of each

transition box and securely tighten the associated

5∕16-18 × ¾ hex-head stainless steel cap screws.

STEP 25. Replace the bottom plates, which were removed in

Step 7 on page 13, to the underside of the high-speed

base and securely tighten the associated ½-13 x 1¼

or ½-13 x 1¾ galvanized steel cap screws, at

washers, and nuts. See Figure 8 on page 13.

For circuit-switchers rated 161 kV and 230 kV:

Attach the six 13-inch x 3¼-inch adjustment plates

to the underside of the high-speed base. These

plates are used to cover small gaps between the

bottom plates, the operator support tube mounting

plate, and the mounting pedestal.

STEP 26. Insert the motor and closing circuit fuseholder, and

then close the control-source disconnect knife

switch. See Figure 29.

STEP 27. Press the CLOSE pushbutton or send a Close signal

to the switch operator. See Figure 23 on page 22.

The closing latch will release, discharging the

closing spring. This action closes the interrupters.

The switch-position indicator on the high-speed

base will move to the Closed position. Further, if

the position-indicating lamp option has been

specied, the red lamp will light.

STEP 28. When the circuit-switcher is ready to be placed in

service, the motor and closing circuit fuses can—at

the user’s option—be replaced with the slugs

furnished. This practice is recommended for

increased reliability because low-voltage fuses can

be damaged by the repeated inrush current

experienced during normal circuit-switcher

opening operations and can “sneak out,” leaving the

circuit-switcher inoperable.

NOTICE

Before replacing these fuses with slugs, make certain

that the control-source battery is adequately protected to

prevent discharge using fuses or circuit breakers located

at the battery bus.

STEP 29. Please complete and mail the circuit-switcher

registration card. The information requested on

this card is vital to ensure prompt notication in the

event eld modications are needed.

Knife switch

Motor and closing circuit fuse holder

Figure 29. Motor and closing circuit fuse holders. Control source

knife switch.

Surge suppressor out

of place.Push the surge

supressor (if present)

back into place.

Motor contactors and

auxiliary contactors should

be fully seated

Figure 30. Check the motor contactor and the surge suppressor

behind the operator side panel.

Optional

relays

Relay

retaining

plate

Figure 31. Check that all optional “ice-cube” style relays are fully

seated and that the retaining plate is in place.

Loading...

Loading...