S&C Instruction Sheet 663-590 11

Table 3

Table 3. Inspection and Maintenance Procedures for the Enclosure and for Components in High-Voltage

Compartments

①—Continued

Item Procedures

Inspect and clean

interior

1 Visually inspect the interior of each compartment for excess dirt, weeds, rodent, reptile, and insect intrusion.

2. If cleaning is necessary, S&C recommends using water to wash dirty or contaminated surfaces. Mild soap may be used to

remove particularly stubborn deposits on painted surfaces, barriers, and Cypoxy™ Insulator parts.

3. Inspect insulators, surge arrestors, terminators, etc., for physical or electrical damage.

4. Check that gasketing around the low-voltage compartment is securely affixed and grouting around the base of the unit is in good

condition. Verify there has been no major water ingress.

Inspect barriers and

minimum air clearances

1. Inspect barriers for signs of tracking and corona discharge. Surface deposits can be wiped off. If surface erosion is present, the

barriers may need to be replaced.

2. Verify interphase and end barriers hang vertically and retaining hardware securely holds them in place. Be sure the switch-side

interphase barriers are properly seated in the support notch (if present) in the lower rear and lower front (25 kV only) of the

compartment.

3. Verify the clearance from the terminators and other energized parts to the barriers and electrical ground is maintained to prevent

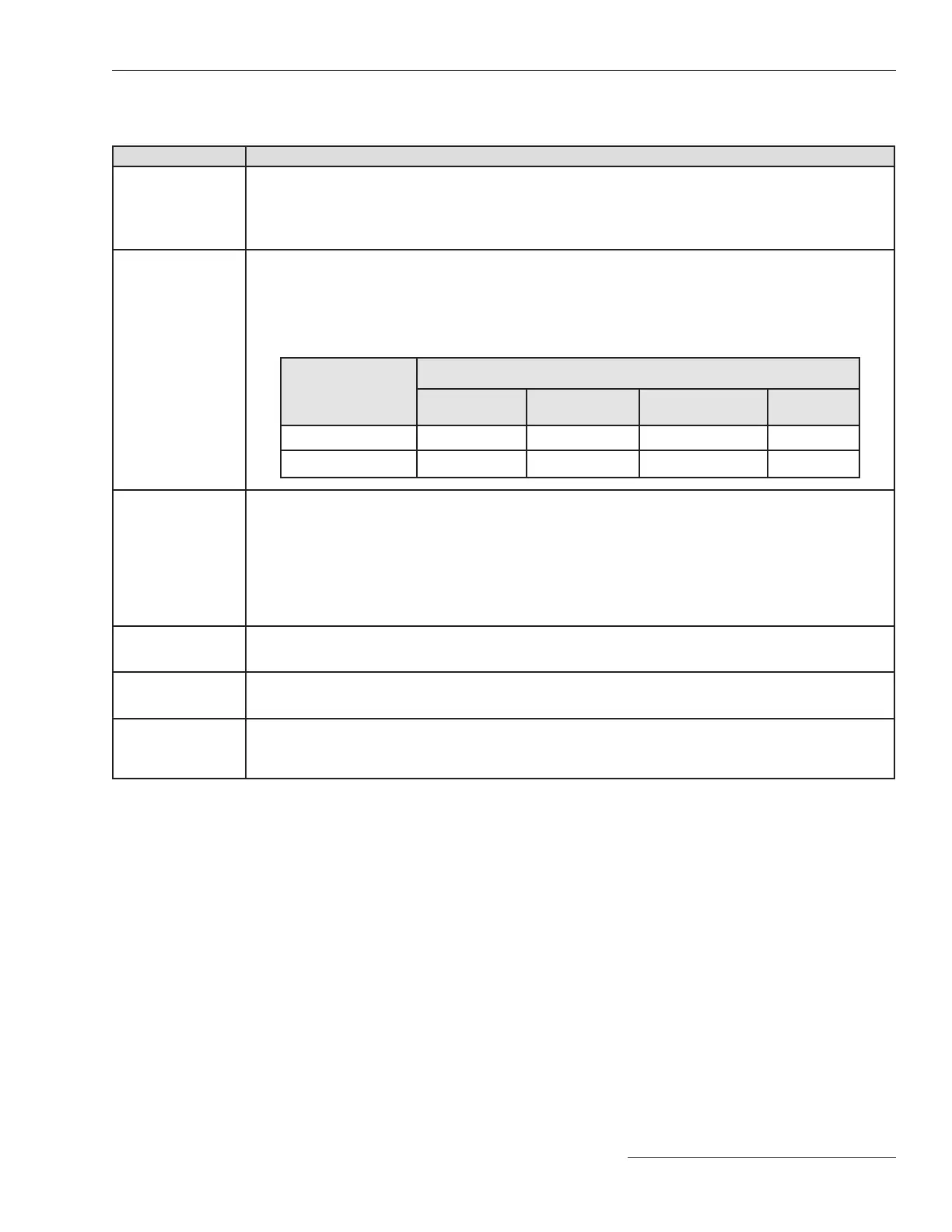

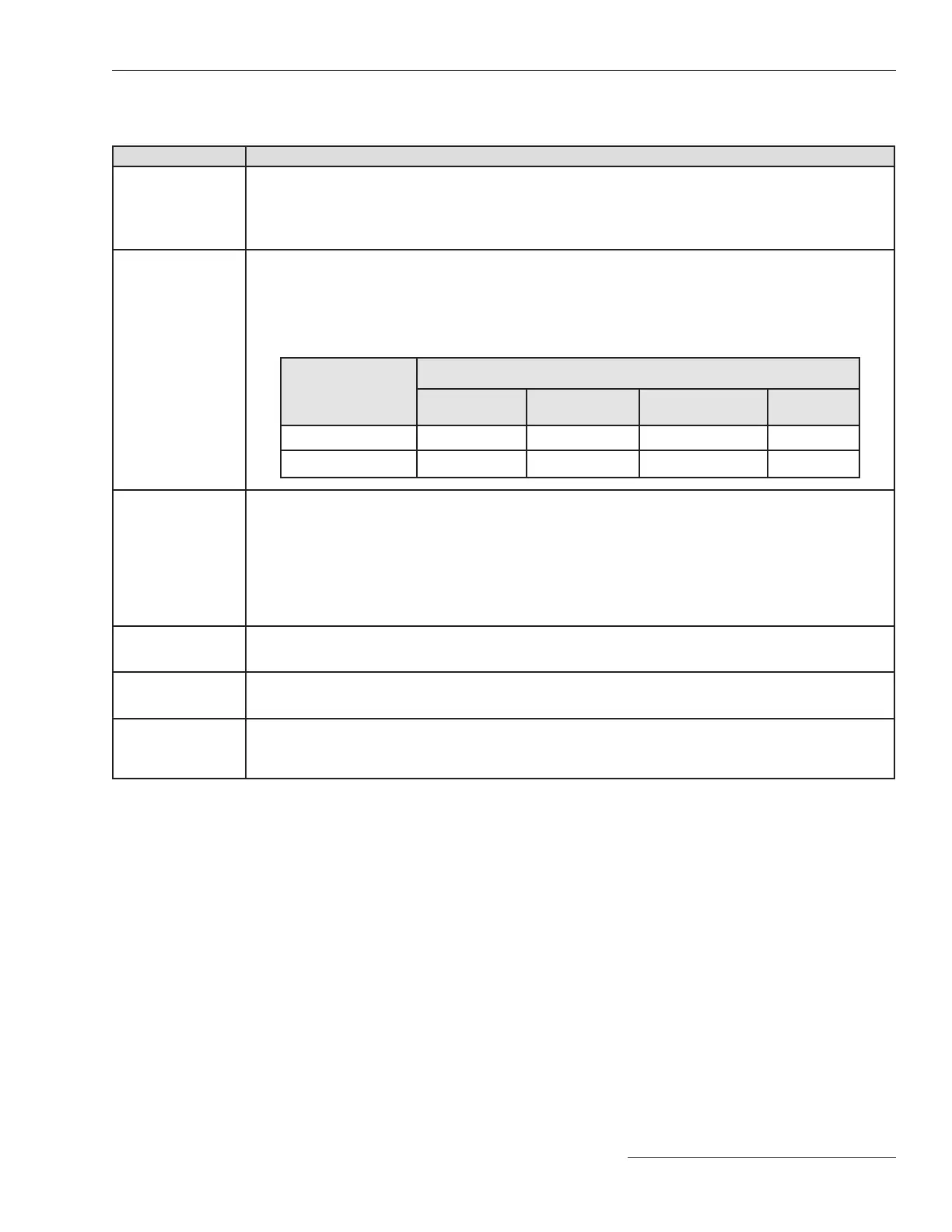

flashover (e.g., fuse silencer to terminator drain wire). Minimum air clearances are listed below:

Rating, kV

Minimum Air Clearances, Inches (mm)

Energized Parts to

Barriers

Terminator Skirts

to Barriers

Energized Parts to

Elec. Ground

Phase-to-

Phase

14.4 1 (25) ½ (13) 6 (152) 6 (152)

25 2¼ (57) 1¼ (32) 7½ (191) 7½ (191)

Inspect and exercise

Mini-Rupter Switches

1. Exercise the Mini-Rupter Switches and check all blades for proper opening and closing. Make sure barriers are not in an open

gap.

2. Inspect, clean, and re-lubricate the Mini-Rupter Switches.▲

a. Check blades for signs of galling and excessive arc interruption. Minor surface imperfections can be burnished out. Clean the

blades and apply a thin layer of lubricant, as necessary.

b. Clean rotating hinge contacts and apply a thin layer of lubricant, as necessary.

c. Check contacts and joints for signs of overheating, as evidenced by distorted or discolored metal.●

Note: S&C recommends the cleaning and re-lubrication of Mini-Rupter Switches every 10 years, regardless of condition, to ensure

proper operation, or more frequently if the environment is excessively hot, humid, dry, dirty, or contaminated.

Inspect fuses 1. Open and close fuses to ensure proper latching. Refer to the applicable S&C instruction sheet for fuse handling instructions.

2. Inspect the fuse contact surfaces for signs of galling and overheating, as evidenced by distorted or discolored contacts.● Minor

imperfections can be burnished out. Clean contacts and apply a thin layer of lubricant, as necessary.▲

Inspect key interlock

and door latching

mechanisms

1. Verify proper functioning of key interlocks, if furnished.

2. Verify proper operation of the door latching mechanisms.

Touch up exterior 1. To maintain the original integrity of the finish, clean the exterior of the gear and touch up scratches and abrasions using S&C

touch-up finish and red-oxide primer, available in aerosol spray cans. Order by catalog number 9999-058 for olive-green finish,

9999-080 for light-gray finish, 9991363-493 for seafoam green finish, 9991363-488 for equipment green finish, and 9999-061 for

red-oxide primer.

① If maintenance is required beyond the scope of this publication or if

replacement parts are necessary, contact the nearest S&C Sales Office.

Have the complete catalog number of the gear and date of shipment (as

shown on the nameplate) available for reference.

▲ Do not use industrial strength cleaning solutions (e.g., Formula 409®,

Simple Green®) or lubricants that contain solvents. Solvent vapors can

attack arc compressor components and fuse pull-rings, resulting in reduced

interrupting performance or weakened parts. NYE Rheolube 368 (available

in small ¼-oz. tubes from S&C, part number 9999-044) is the only approved

lubricant.

● There may be discoloration of copper or copper alloy surfaces caused by

oxidation. This, however, does not indicate overheating.

Loading...

Loading...