CD MECHANISM ADJUSTMENTS

.. .

3. CD MECHANISM

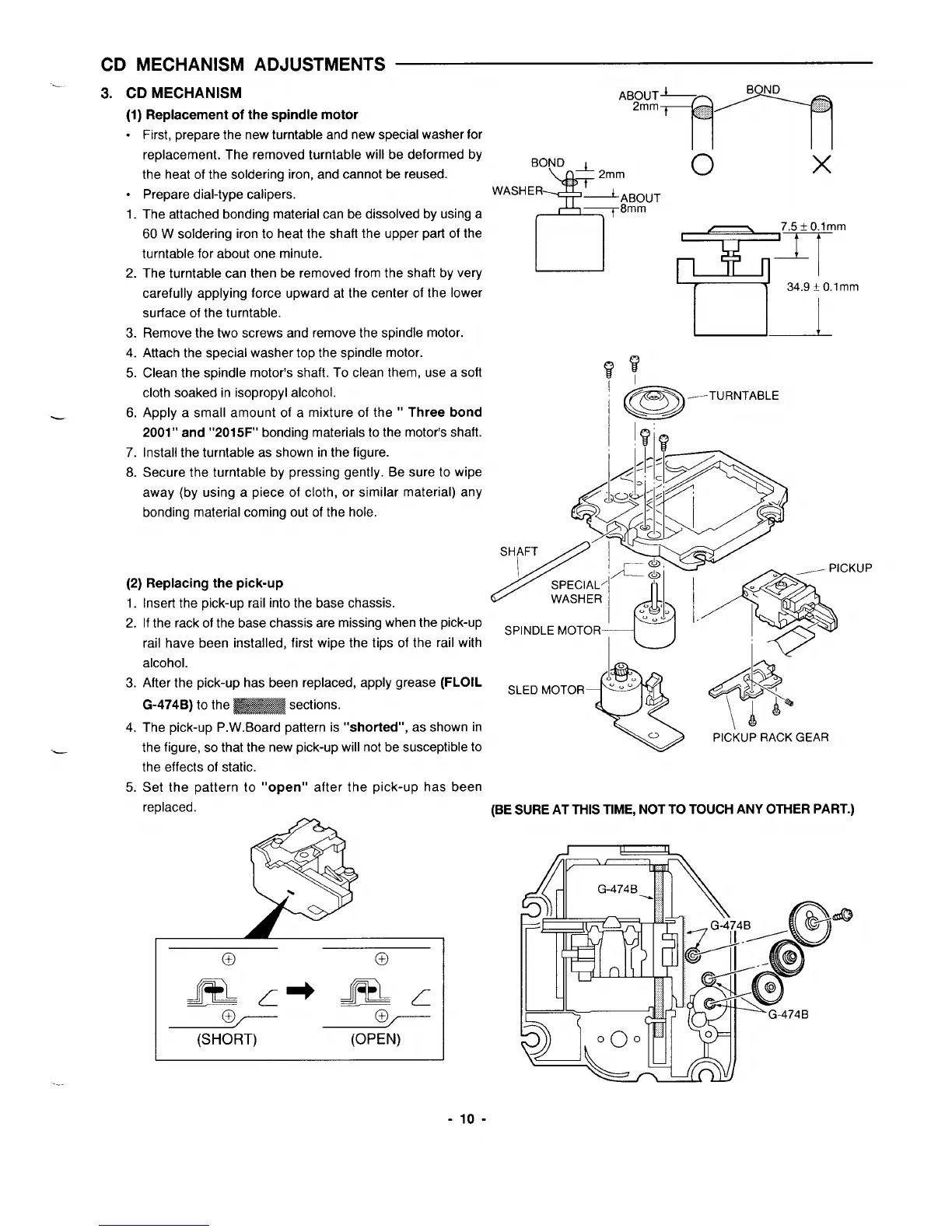

(1) Replacement of the spindle motor

“$::%-

.

.

1.

2.

3.

4.

5.

6.

7.

8.

First, prepare the new turntable and new special washer for

replacement. The removed turntable will be deformed by

BOND ~

the heat of the soldering iron, and cannot be reused.

6

2mm

Prepare dial-type calipers.

WASHER

‘ABOUT

The attached bonding material can be dissolved by using a TSmm

60 W soldering iron to heat the shaft the upper part of the

turntable for about one minute.

The turntable can then be removed from the shaft by very

carefully applying force upward at the center of the lower

surface of the turntable.

Remove the two screws and remove the spindle motor.

Attach the special washer top the spindle motor.

Clean the spindle motor’s shaft. To clean them, use a soft

?y

II

II

o

x

cloth soaked in isopropyl alcohol.

1’

‘m

—-TURNTABLE

Apply a small amount of a mixture of the “ Three bond

2001” and “2015F’ bonding materials to the motor’s shaft.

Igio

1.

2.

3.

4.

.—

5.

Install the turntable as shown in the figure.

Secure the turntable by pressing gently. Be sure to wipe

away (by using a piece of cloth, or similar material) any

bonding material coming out of the hole.

<;G

: ; ~~

H’a

SHAFT

I

‘L$’

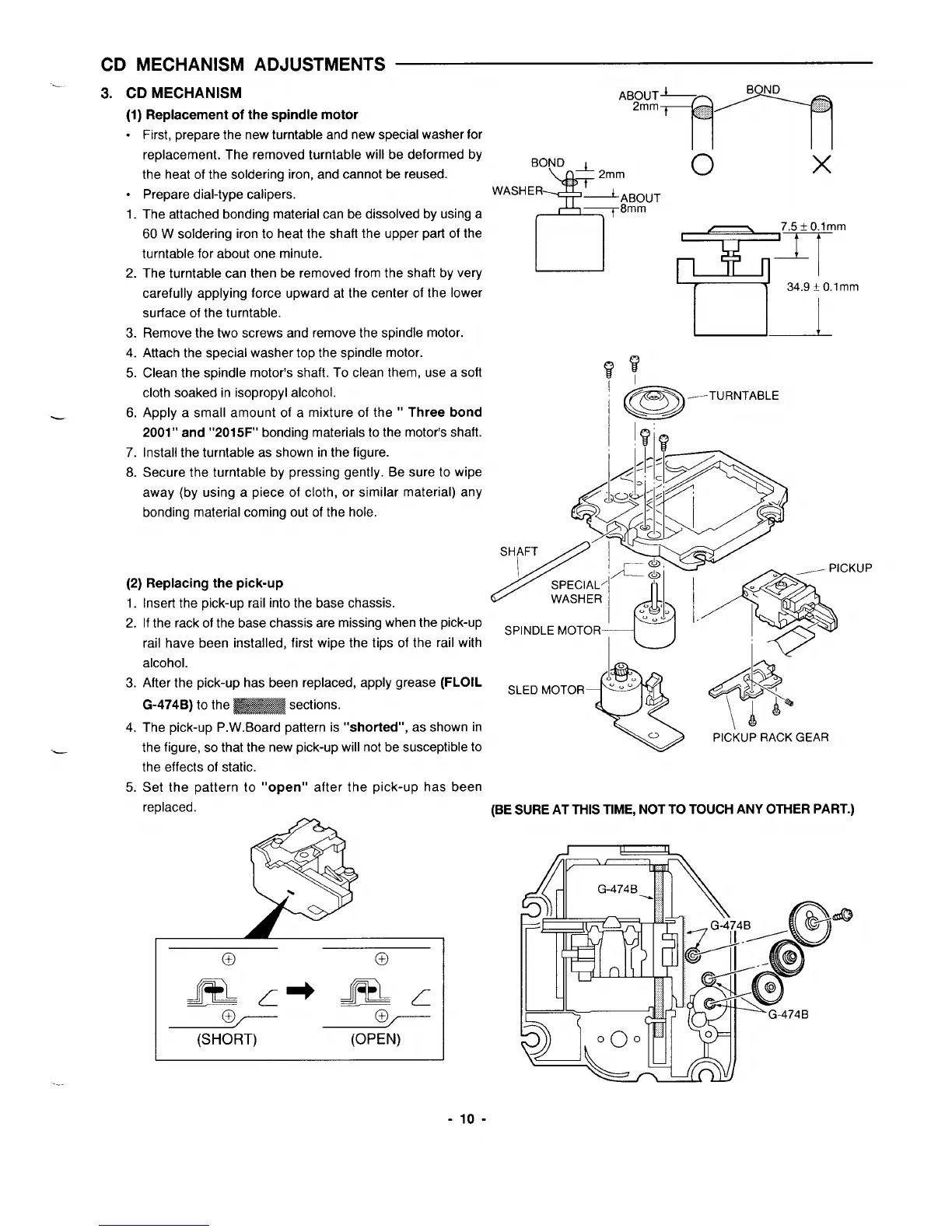

(2) Replacing the pick-up

SPECIAL/

&

-. @~ “CKUP

Insert the pick-up rail into the base chassis.

WASHER

UC

If the rack of the base chassis are missing when the pick-up

. .

u“. .

SPINDLE MOTOR

/

rail have been installed, first wipe the tips of the rail with

*

alcohol.

@

.

After the pick-up has been replaced, apply grease (FLOIL

SLED MOTOR “o“‘o

&&

.

“1

G-474B) to the _ sections.

\iA

%

The pick-up P. W. Board pattern is “shorted”, as shown in

c1

the figure, so that the new pick-up will not be susceptible to

PICKUP RACK GEAR

the effects of static.

Set the pattern to “open” after the pick-up has been

replaced.

(BE SURE AT THIS TIME, NOT TO TOUCH ANY OTHER PART.)

fiiL~+mz

@-

qz-----

(SHORT)

(OPEN)

-1o-

Loading...

Loading...