25GB

Troubleshooting

The determination of the causes of these interference and their elimination always require heightened attention and caution.

Pull the mains plug!

In the following are some of the most common interferences and their causes listed. If you cannot correct faults and errors with

the machine, please contact your dealer.

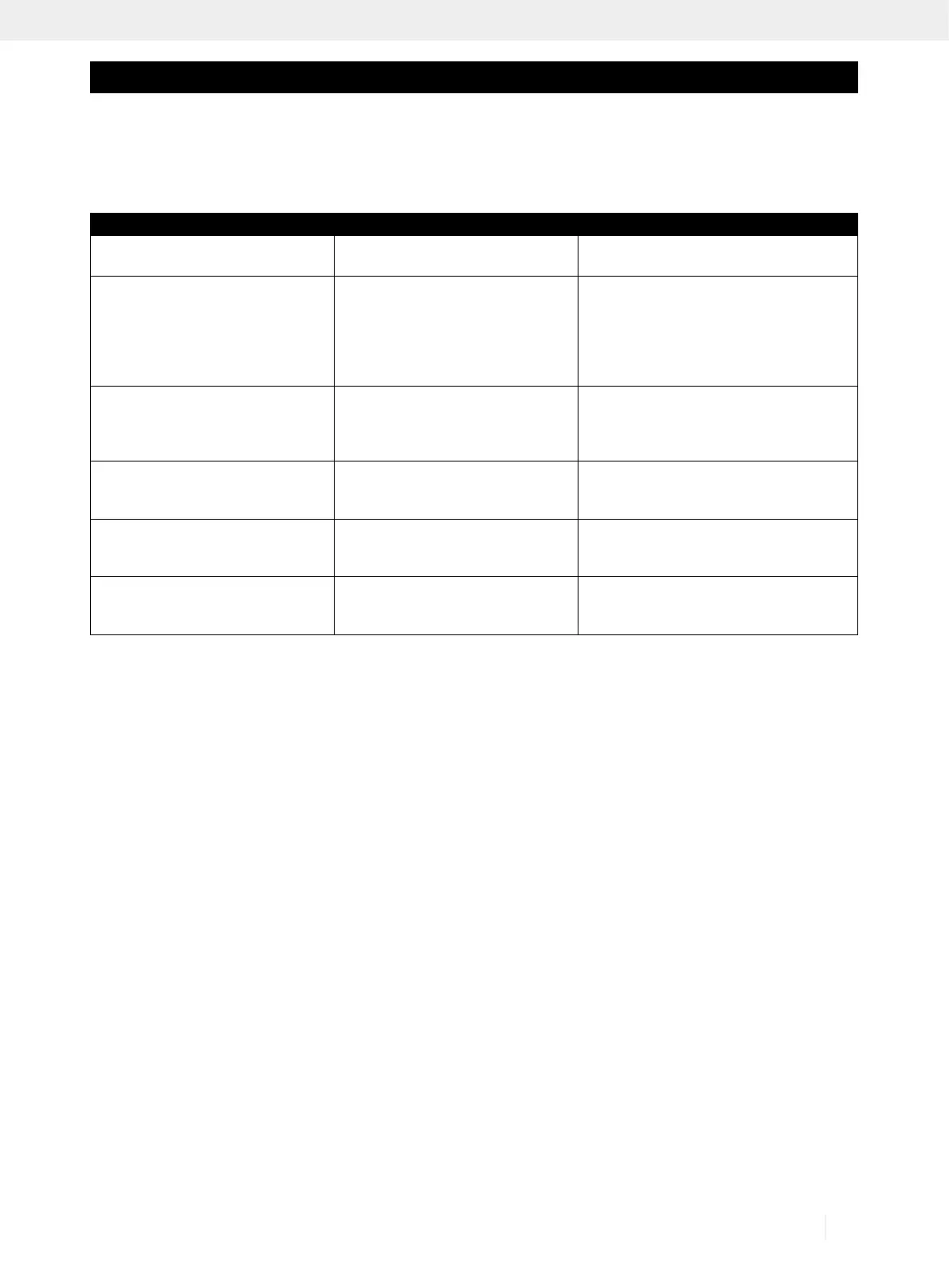

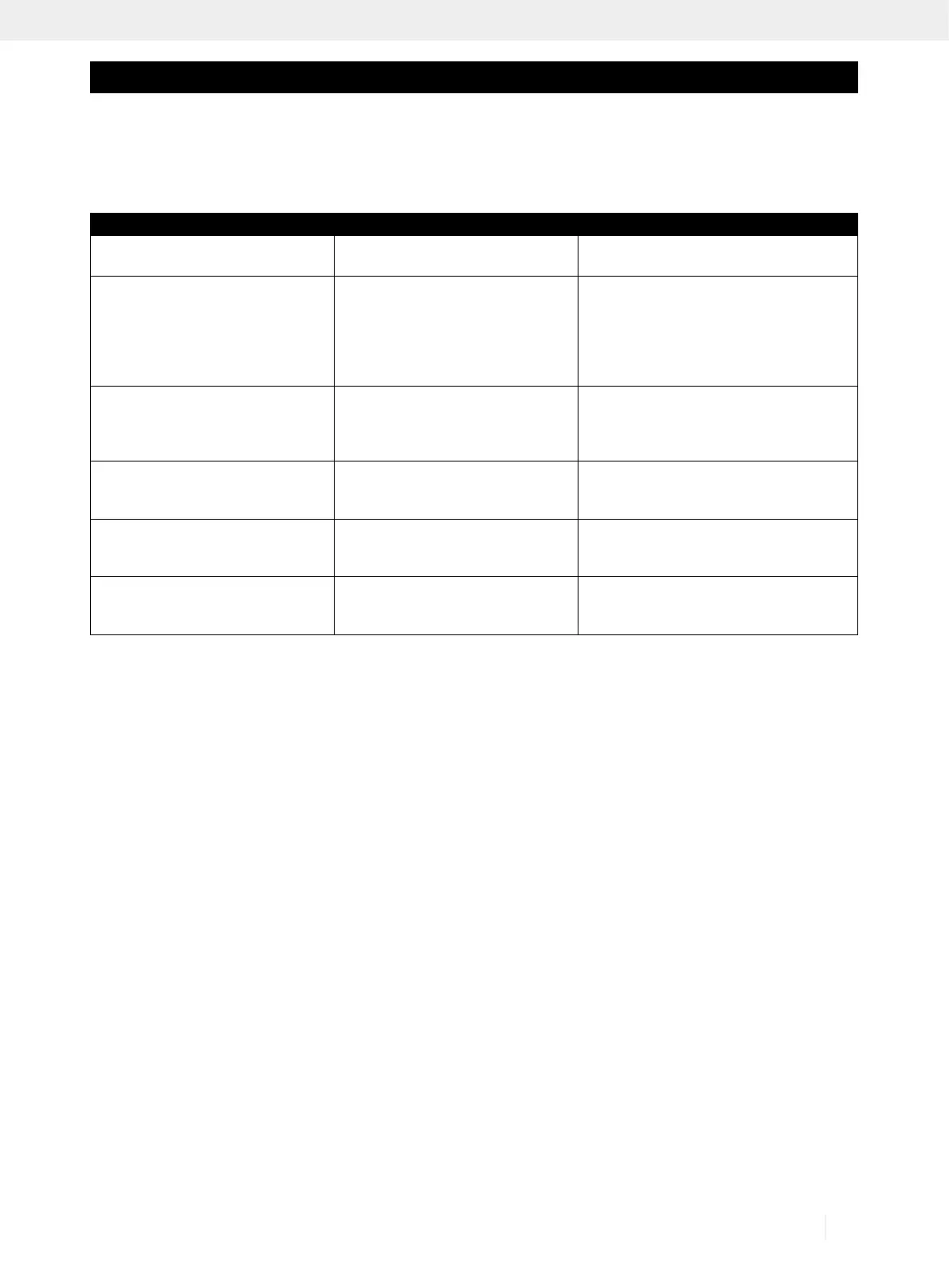

Disturbance Probable cause Help

Machine cannot be switched on No mains voltage available.

Carbon brush conductors worn out.

Control Voltage supply

Bring Machine into the service center

Machine switches off during the no-

load operation independently

Power failure Control Net-lateral Pre-fuse

The machine does not restart by the

inserted under-voltage protection automati-

cally and must again be switched on after

tension return.

Machine remains during working on

standstill

Response of the overload protection

because of blunt measurers or of too

large feed motion and/or thickness of

chip

Before continuing with work exchange

measurers and/or wait for cooling of the

engine.

Number of revolutions drops during

the treatment

Too large splinter acceptance

Too large feed motion

Milling cutter blunt

Reduce Splinter acceptance

Reduce Feed speed

Replace milling cutter

Careless milling picture Milling cutter blunt

Uneven feed motion

Replace milling cutter

Work with constant pressure and reduced

feed motion

Splinter ejection clogs (without ex-

haust)

Too large splinter acceptance

Milling cutter blunt

Too wet wood

Reduce Splinter acceptance

Exchange milling cutter

Loading...

Loading...