Instructions for Use – SCHMIDT

®

Flow Sensor SS 20.600 Page 16

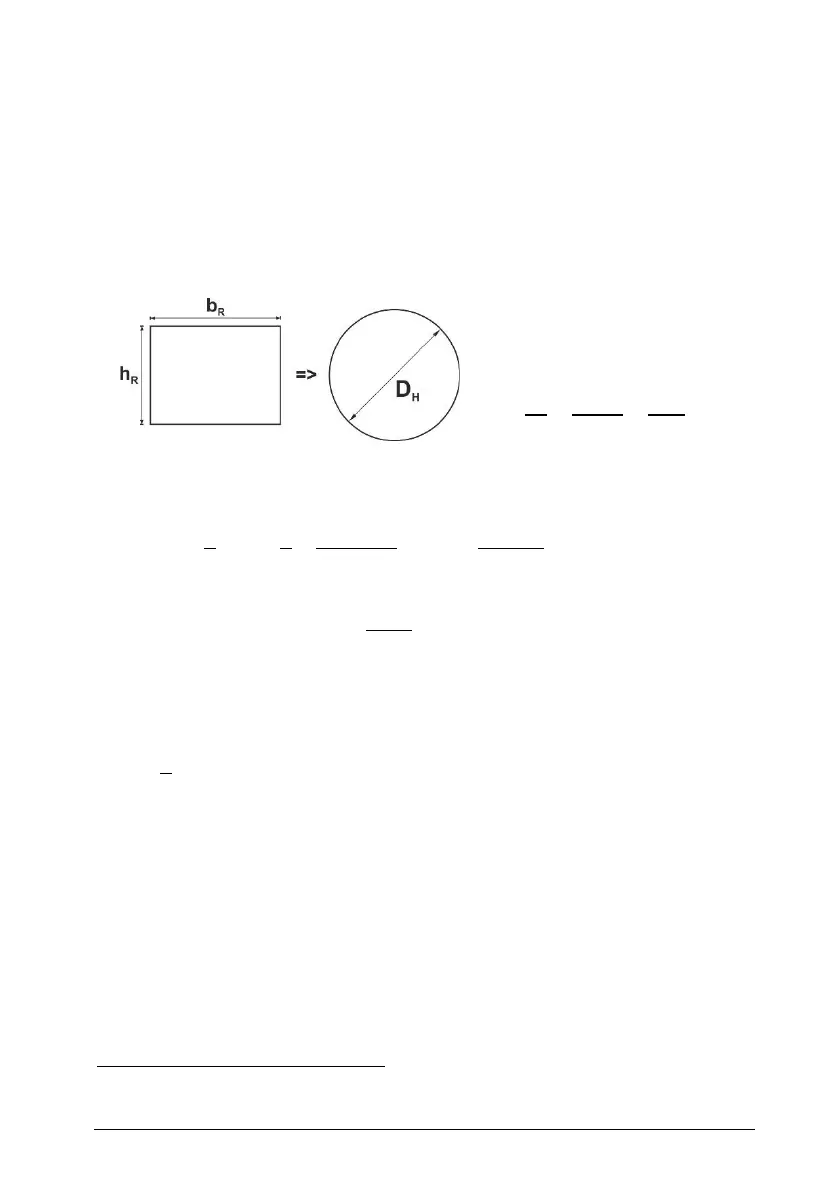

Quasi-parabolic flow profile

The system length is large compared to the cross-section surface and

the flow velocity is so high that the ratios correspond to that of the cir-

cular pipe. This means that the same requirements apply here to the

installation conditions.

Since the situation is similar to that in a pipe

, the volume flow in a

square chamber can be calculated by equating the hydraulic diameter

of both cross-section forms. The result for a rectangle “R” according to

Figure 3-5 is a hydraulic “pipe diameter” D

H

:

b

R

: Width of rectangular channel

h

R

: Height of rectangular channel

D

H

: Hydraulic pipe diameter

Figure 3-5

According to this, the volume flow in a shaft is calculated as:

Width/height of the square chamber [m]

Hydraulic inner diameter of the chamber [m]

Cross-section area of the equivalent pipe [m

2

]

Maximum flow velocity in the middle of the pipe [m/s]

Average flow velocity in the pipe [m/s]

Standard volume flow [m

3

/s]

Typical applications are:

o Ventilation shaft

o Exhaust air duct

The profile factors are equal for both cross-section forms.

Loading...

Loading...