Page 11

Page 11

NOTE

. If in the 5 minutes length of the water

filling phase the machine sump reservoir

does not get filled with water up to the rim of

the overflow pipe, it is advisable to check:

1.The water pressure of the water supply line

that must be at least 1 bar (14 psig) Minimum

(Max 5 bar-70 psig).

2.The filtering device installed in the water

line that may reduce the water pressure below

the Minimum value of 1 bar (14 psig).

3. Any clogging situation in the water circuit

like the inlet water strainer and/or the flow

control.

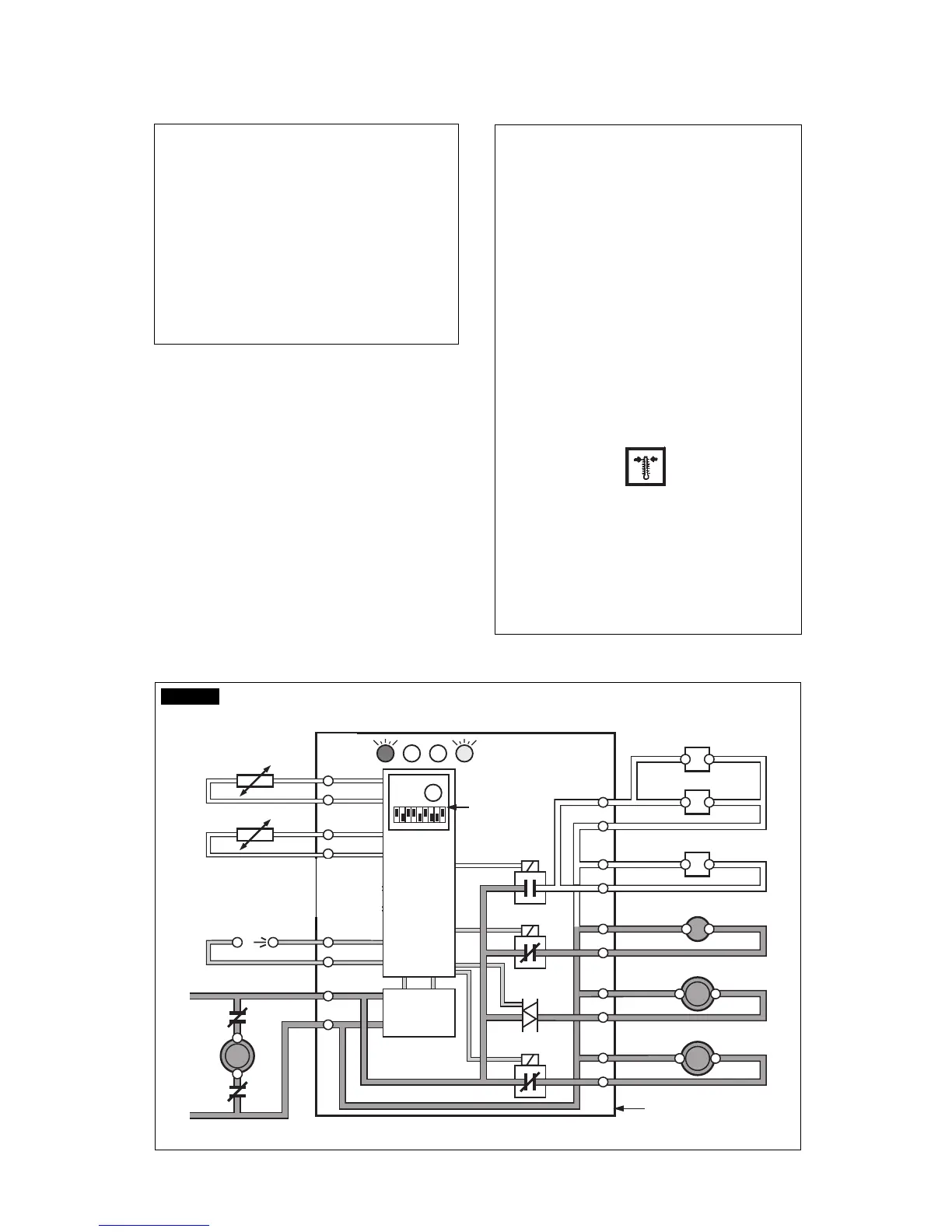

C. At completion of the water filling phase (5

minutes) the unit passes automatically into the

freezing cycle with the start up of:

COMPRESSOR

WATER PUMP

FAN MOTOR/S (in air cooled version) controlled

by the condensing temperature sensor located

within the condenser fins (Fig.2).

OPERATIONAL CHECKS

D. If necessary install the refrigerant service

gauges on both the high side and low side

Schräder valves to check the compressor head

and suction pressures.

NOTE.

On air cooled models the condenser

temperature sensor, which is located within

the condenser fins, keep the head

(condensing) pressure between 16 and 18

bars (225-250 psig).

In the water cooled models the discharge

pressure is kept constant at the value of 17

bars (240 psig) by means of a water regulating

valve located on the water supply line to the

condenser.

In case of condenser clogging such to prevent

the proper flow of the cooling air or, in case

the fan motor is out of operation or shortage

of water in the water cooled condenser, the

condenser temperature rises and when it

reaches 70

°

C (160

°

F) - for air cooled version

- or 60

°

C (140

°

F) - for water cooled version -

the condenser temperature sensor shuts-off

the ice maker with the consequent light-up of

the RED WARNING LED (Fig.3).

After having diagnosed the reason of the rise

of temperature and removed its cause, it is

necessary to unplug (wait few seconds) and

plug in again the unit, thus to put the machine

in condition to initiate a new freezing cycle.

The machine restarts with the usual 5 minutes

water filling phase in order to provide enough

water into the sump tank.

16

15

14

13

2

1

7

8

9

10

3

4

5

6

11

12

Rx Tx

WATER IN VALVE

HOT GAS VALVE

CONTACTOR COIL

FAN MOTOR

WATER PUMP

- EVAPORATOR

- AMBIENT

- CONDENSER

TEMPERATURE SENSORSBINCOMPRESSOR

TRANSF.

DATA

PROCESSOR

ELECTR.

TIMER

DIP

SWITCH

ELECTRONIC CARD

L

N

RELAYS

RELAY

TRIAC

WATER DRAIN VALVE

FIG. 2

Loading...

Loading...