Page 22

Page 22

H. WATER SPRAY SYSTEM

Through its nozzles, the water pumped, is sprayed

in each individual cup to be frozen into ice.

It consists of one spray tube wheve are located

several spray nozzles.

I. WATER PUMP

The water pump operates continually throughout

the freezing cycle and on the first 15 or 30

seconds of the defrost cycle so to such the

remaining water from the sump tank (reach in

mineral salts) and drain it out.

During the freezing cycle the pump primes the

water from the sump to the spray system and

through the spray nozzles sprays it into the

inverted cup molds to be frozen into crystal clear

ice cubes.

It is recommended that the pump motor bearings

be checked at least every six months.

J. WATER INLET SOLENOID VALVE -

3/4 GAS MALE FITTING

The water inlet solenoid valve is activated by the

micro processor of the P.C. BOARD during the

first 5 minutes of water filling phase and as well

during the defrost cycle.

When energized it allows a metered amount of

incoming water to flow overt he evaporator cavity

to assist the hot gas in defrosting the ice cubes.

The water running over the evaporator cavity

drops by gravity, through the dribbler holes of

the platen, into the sump reservoir where it will be

sucked by the water pump and primed to the

spray system.

K. HOT GAS SOLENOID VALVE

The hot gas solenoid valve consists basically in

two parts: the valve body and the valve coil.

Located on the hot gas line, this valve is energized

through the micro processor of P.C. BOARD

during the defrost cycle and as well during the

water filling phase.

LENGTH OF TIMED PORTION OF FREEZING CYCLE ACCORDING TO THE

DIP SWITCH SETTING COMBINATIONS

TAB. B

size of the cubes (Large or Medium) as per the

following setting:

ON ON : PROGRAM A

ON OFF : PROGRAM B

OFF OFF : PROGRAM C

OFF ON : PROGRAM D

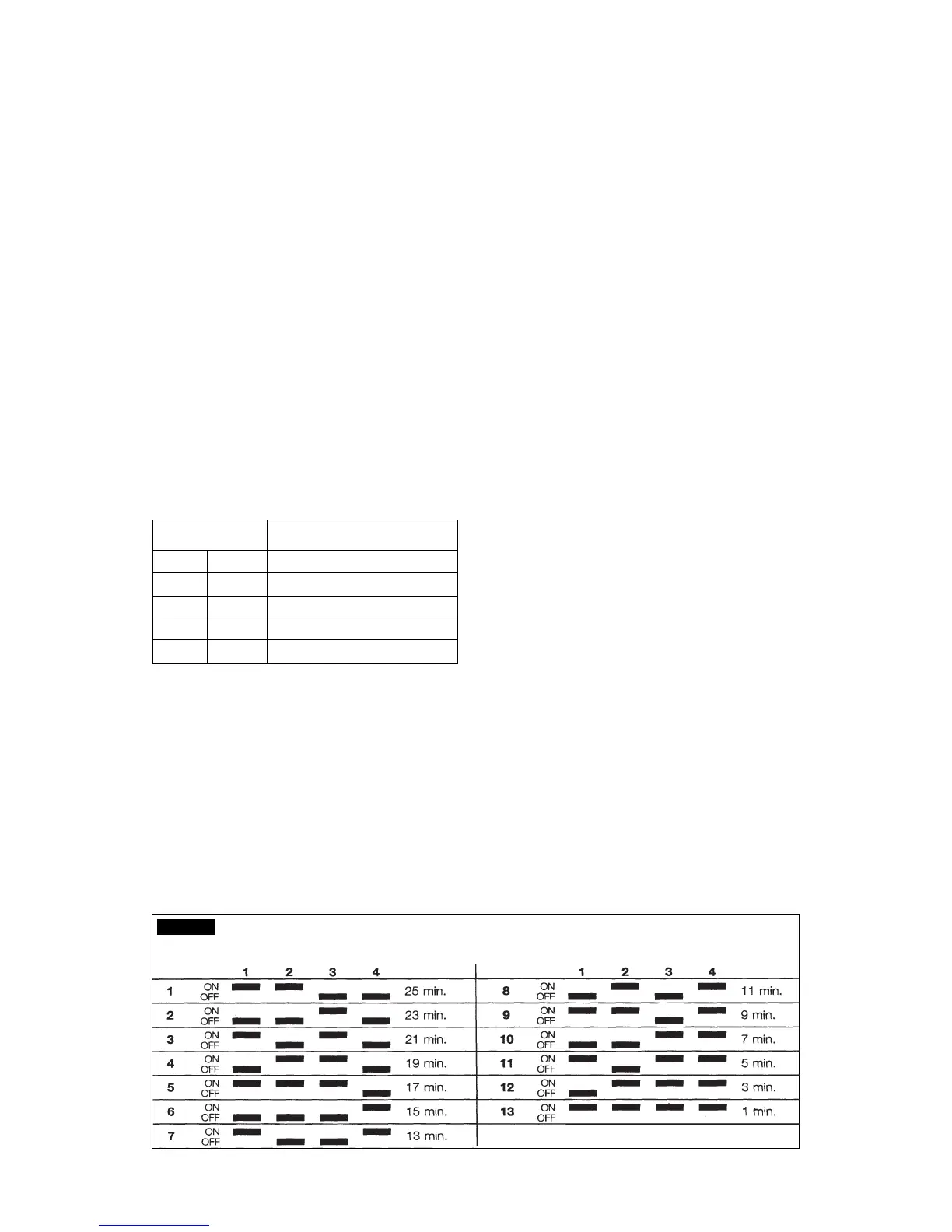

LENGTH OF HARVEST CYCLE

ACCORDING TO THE TIME TO DROP THE

EVAP. TEMPERATURE FROM 0°C TO -15°C

LENGTH PROGRAMS

HARVEST

CYCLE

ABCD

180” Up to 6’30” *** Up to 9’30” xxxx

165” 6’30”-7’ Up to 3’ 9’30”-10’ xxxx

150” 7’-8’ 3’-3’15’ 10’-11’ xxxx

135” 8’-9’ 3’15”-3’30” 11’-12’ xxxx

120” 9’-10’30” 3’30”-4’30” 12’-13’30” < 3'

105” 10’30”-12’ 4’30”-6’ 13’30”-15’ 3' - 4'

90” >12’ >6’ >15’ > 4'

The DIP SWITCH N° 7 and 8 allow the extention

of the length of the harvest/defrost cycle according

to their combination as per following chart:

DIP SWITCH ADDITIONAL DEFROST TIME

78

ON ON 0

OFF ON 30"

ON OFF 60"

OFF OFF WATER PUMP OFF

The 9th key is used to supply power to the water

pump for the first 15 seconds of the defrost cycle

- position OFF - or for the first 30 seconds -

position ON.

The 10th key is used to modify the CUT-OUT

condensing temperature from 70°C (160°F) for

the air cooled versions - ON position - to 60°C

(140°F) - OFF position - for the water cooled

versions.

Loading...

Loading...