FLITE

2

50 mg/m

3

for 207 bar apparatus

35 mg/m

3

for 300 bar apparatus

Note:

The water content of air supplied by a

compressor must not exceed 35 mg/m

3

.

Contaminants must be kept to a minimum

and must not exceed permissible

exposure levels. Air filters must be

suitable for the quality of air used and the

air must be tested periodically to ensure

that the supply reaches these standards.

The air must be free from the odour of oil

(odour threshold is 0.3 mg/m

3

).

The dew-point of air for compressed

airline BA must be sufficiently low to

prevent internal freezing.

National regulations for compressed

airline BA must be observed.

1.4 COMPRESSED AIR

AIRLINE SUPPLIES

Air for use with compressed air airlines

must conform to EN 12021 : 1999 or

AS/NZS1715 : 1994.

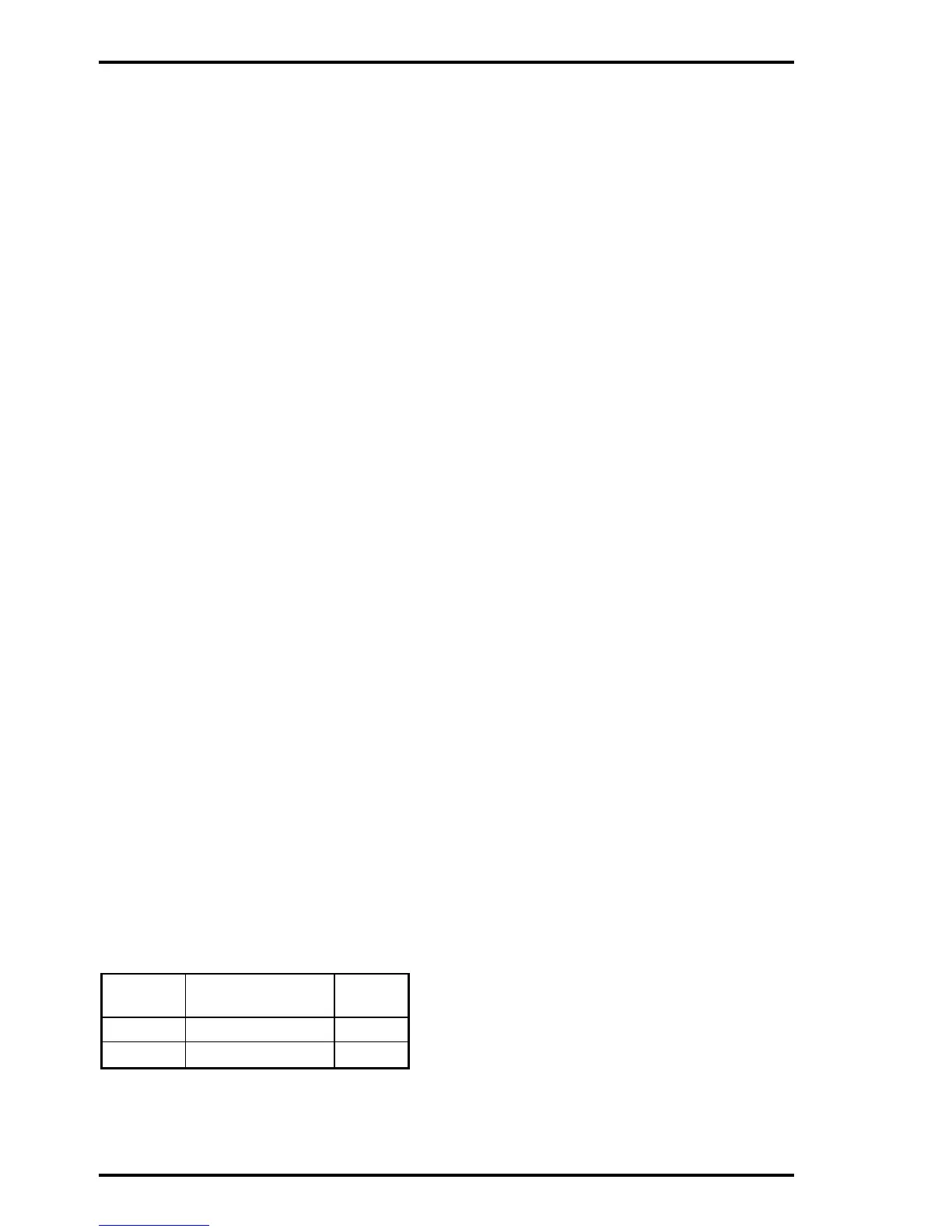

Airline pressure must be between 5.0 and

9.0 bar (70 - 130psi). Airflow supply

capacity for a single airline is given in

Table 2. Generally, each additional

wearer requires an extra 150 L/min, each

additional pair of wearers requires 300

L/min for one wearer and 450 L/min for

two wearers (see Table 2). All

measurements must be taken at the

wearer end of the airline. An Airline Flow

Tester (Article Number 1035978) is

available from Scott Safety for this

purpose.

Example: for 8 users (4 pairs) the

recommended flow is 4 x (300 + 150) =

1800 litres per minute.

External air supplies must conform to the

Supply Pressures and Flow Rates listed

in Table 2 when measured at the extreme

end of the supply hose.

Table 2: Wearer Air Consumption

1.5 TRAINING

Personnel who use breathing apparatus

must be fully trained in accordance with

these instructions and national

regulations.

These instructions cannot replace an

accredited training course run by fully

qualified instructors in the proper and

safe use of Scott Safety breathing

apparatus.

Please contact Training and Technical

Support Services or your Scott Safety

distributor for training course details.

Training and Technical Support

Services:

Scott Safety

Pimbo Road, West Pimbo,

Skelmersdale, Lancashire,

WN8 9RA, England.

Tel: +44 (0) 1695 711711

Fax: +44 (0) 1695 711775

1.6 SERVICING

FLITE must be serviced at scheduled

intervals by personnel who have

completed a formal training course and

hold a current certificate for servicing and

repairing Scott Safety breathing

apparatus. Details of the servicing

schedule are contained within the Scott

Safety FLITE Service Manual, copies of

which may only be obtained by registered

holders of a current certificate. Your

Scott Safety distributor or Training and

Technical Support Services at Scott

Safety will be pleased to provide training

course details and quotes for service

contracts. Please see above for contact

details.

1.7 PARTS IDENTIFICATION

All safety-related parts accessible to

wearers are clearly marked with a part

number and a serial number. Other parts

must only be removed or adjusted by

personnel qualified to service the

apparatus.

Loading...

Loading...