TB-9017 Page 3 of 6

© 2015 DESCO INDUSTRIES, INC.

Employee Owned

SCS - 926 JR Industrial Drive, Sanford, NC 27332 • (919) 718-0000 • Website: StaticControl.com

2. Qualication of Installed Static Control Surfaces

[Measurement of resistance of the top surface to

the groundable point of the static control surface

(RTS-GP)]. GROUNDABLE POINT is the point

at which the grounding conductor is connected

to the static control surface; the GROUNDABLE

POINT is most commonly a snap (mats), a bolt

(laminate), or a strip of conductive foil tape (ooring).

This QUALIFICATION measurement is similar

to those described in the test description section

and is used to verify the correct installation of the

GROUNDABLE POINT by the manufacturer or by

the user. While the test procedure is the same, the

test setup is slightly different; see Figure 5.

3. Evaluation of Static Control Materials:

[Measurement of the resistance between two points

on top of a static control surface (RTS-TS), and the

resistance between a point on the surface and the

groundable point (RTS-GP)] Material measurements

are done to determine the intrinsic electrical

properties of static control work surface materials.

Note: Values obtained by these tests may not reect

how a material will perform when installed as a static

control surface.

Material evaluations are typically done at two

humidities (12% RH and 50% RH) to determine

whether the electrical properties of the material

are humidity-dependent. If the low humidity test

results are borderline or not within the expected

ranges, caution should be exercised when using

such materials in winter months or in dry conditions.

To assure test accuracy, a minimum of six samples

should be tested.

The test procedure is as follows:

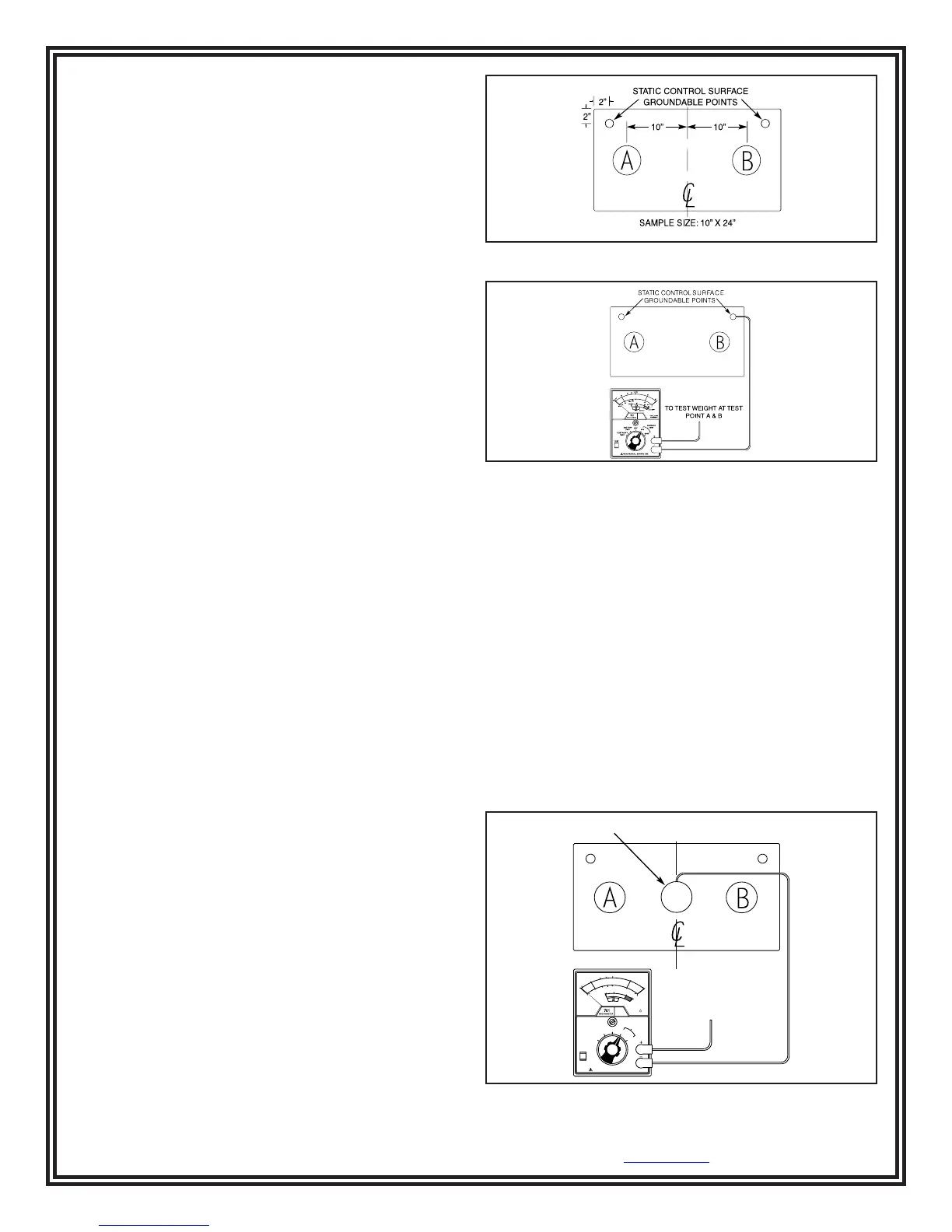

A. Prepare a minimum of six samples of each material

to be tested as shown in Figure 6.

B. Clean samples per manufacturers recommended

cleaning procedures. Condition samples at 73°F

(23° C) and 50% RH for 48-72 hours.

Note: Samples must be maintained at the appropriate

humidity level throughout the test procedures.

C. Complete BATTERY TEST and CONTINUITY TEST.

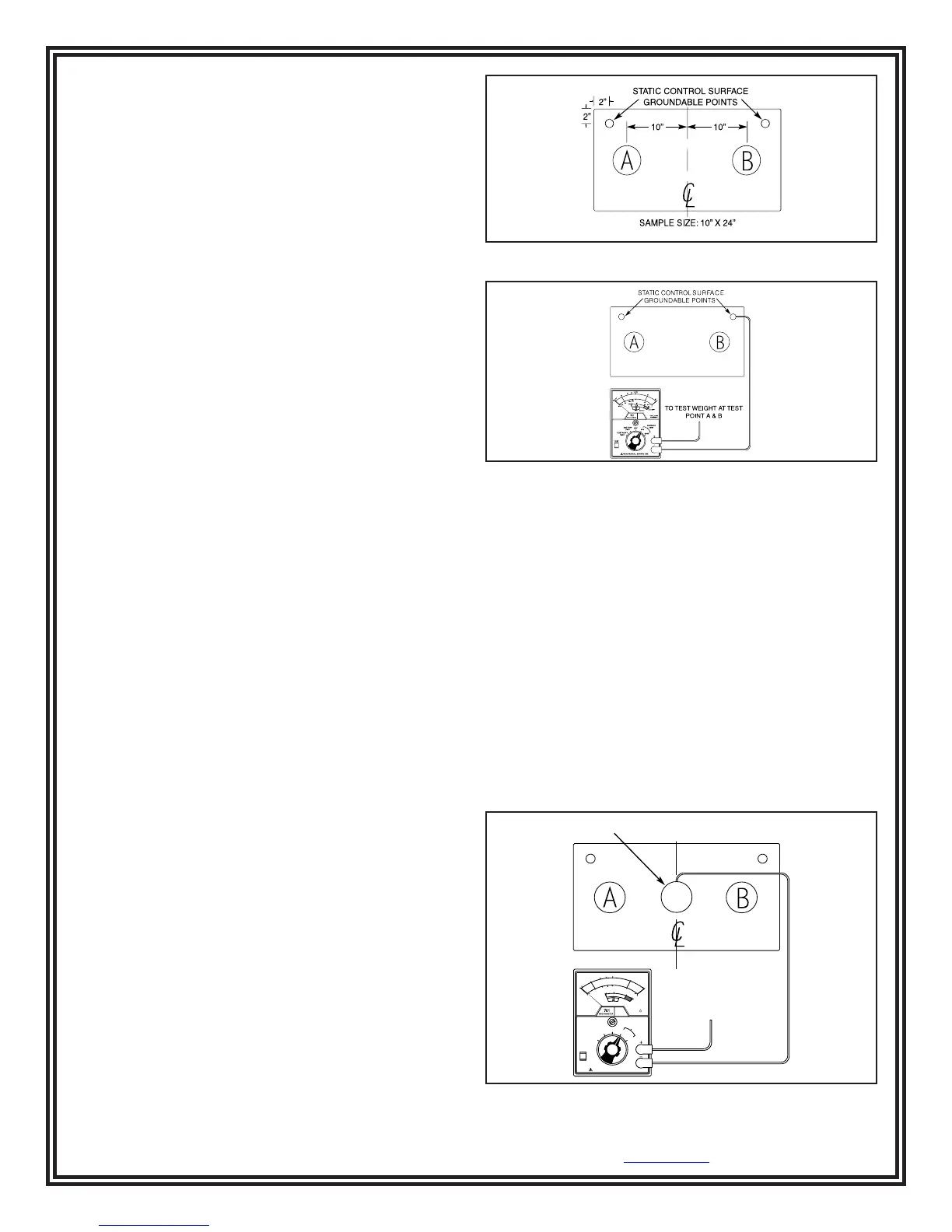

D. Surface-to-Groundable Point Test: Test samples

per Figure 7, using both the 100 volts and 10 volts

SURFACE TEST ranges at 50% RH and record the

values as (RTS-GP).

Figure 6. Material Evaluation Sample Conguration.

Figure 7. Material Evaluation Surface to Groundable

Point Test.

Procedure: Place the SCS 701 Analog Surface Resis-

tance Megohmmeter Kit on a table top or other stable

surface. Connect the test leads to the Tester by means

of the right angle banana plugs. Connect the other end

of one of the leads to one of the test weights and place

the weight on the surface to be tested. Use one of the

supplied clips to connect the other lead to the ground-

able point on the static control surface. Depress TEST

button for 15 seconds and then record the reading.

E. Surface-to-surface Test: Test samples as shown in

Figure 8 use both test weights and repeat the same

test procedure used to determine (RTS-GP).

F. Repeat A through E after conditioning samples at

73°F (23°C) and 12% RH. Use the same test points

and record the values.

OF F

10V

100V

BA TTE RY

TEST

CONTINUITY

TEST

TEST

READ MA NUAL BEFORE US E

OHMS

SURF AC E

TEST

TAUT BAN D

SUSPENSION

10

9

1G

10G

FAIL

PA

S

S

10

10

10

11

100G

10

8

10

7

10

6

10

5

0

1M

100K

0

10M

100M

CONTINUITY

BATTE RY

100V

0

10K

100K

1M

10M

100M

TO

TEST W EIGHT AT

TEST

POINT A & B

STATIC CONTROL SURFACE GROUNDABLE POINTS

Figure 8. Material Evaluation Surface to Surface Test.

Loading...

Loading...