4.3. Switching off

Warning

When the generating set is turned off, the engine continues to give off heat.

Appropriate ventilation should be provided after the generating set is turned off.

To stop the generating set urgently, place the engine switch on "OFF" or "О".

n Take the plugs out of the sockets and allow the engine to run without any charge for 1 to 2 minutes.

o Place the engine switch (no. 10, diag. A) on "OFF" or "О" and the set will stop.

p Close the fuel tap (no. 14, diag. A).

5. Safety features (if fitted, see specifications table)

5.1. Oil cut-out

This mechanism is designed to prevent any damage to the motor resulting from lack of oil in the motor sump. It automatically cuts out

the motor. If the motor stops and will not restart, check the motor oil level before looking for any other cause of the problem.

5.2. Circuit breaker

The electrical circuit of the set is protected by several magnetothermal, differential or thermal cut-out switches. Any overload and/or

short circuits cause the supply of electrical energy to be cut.

6. Maintenance schedule

6.1. Reminder of use

The maintenance interval frequency and the operations to be carried out are outlined in the maintenance programme.

However, it should be added that it is the environment in which the generating set is operating which determines this programme.

Accordingly, if the set is used in extreme conditions, shorter intervals between maintenance procedures should be adopted.

These maintenance schedules apply only to generating sets running on fuel and oil, that conform to the specifications given in this

booklet.

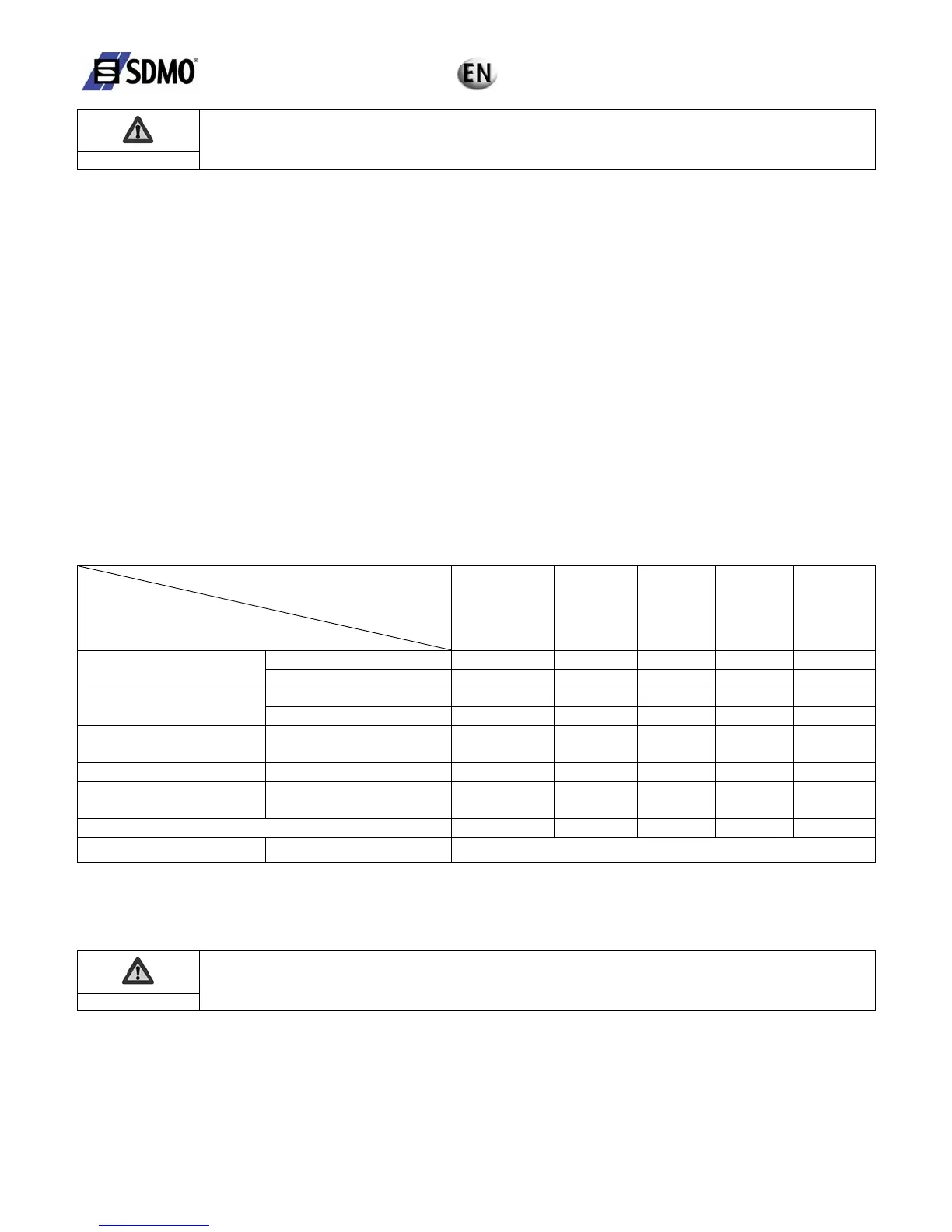

6.2. Maintenance table

Carry out these maintenance procedures at

whichever of the two intervals is

reached first

Part

Each time it is

used

After the

first 20

hours of use

Every 3

months or

50 hours

Every 6

months or

100 hours

Every 12

months or

300 hours

Check the level

•

Engine oil

Change

•

•

Check

•

Air filter

Clean

• (1)

Fuel filter Clean

•

Spark arrester Clean

•

Spark plugs Check / clean

•

Valve clearance Check / adjust

• (*)

Strainer and petrol tank Clean

• (*)

Cleaning the generating set

•

Fuel line Check (replace if necessary) Every 2 years (*)

Note: * This operation should be carried out by one of our agents

(1): Perform air filter maintenance more frequently for operation in dusty locations.

7. Maintenance procedures

7.1. Cleaning the air filter

Danger

Never use petrol or solvents with a low flash point for cleaning the air filter element as this could result in a fire

or explosion.

n Unfasten both retaining clips (no. 1, diag. H) from air filter cover (no. 2, diag. H) and remove the cover.

o Remove foam element (no. 3, diag. H). Check carefully that it has no rips or holes. Replace it if it is damaged.

p Wash the element in a solution of household cleaning product and warm water, then rinse thoroughly, or wash it in non-

flammable solvent or solvent with a high flash point. Allow the element to dry out.

q Soak the element in clean engine oil and remove the excess oil. The motor will emit smoke when it is started for the first time if

too much oil remains in the foam.

r Refit following the reverse procedure to that used for removal.

Loading...

Loading...