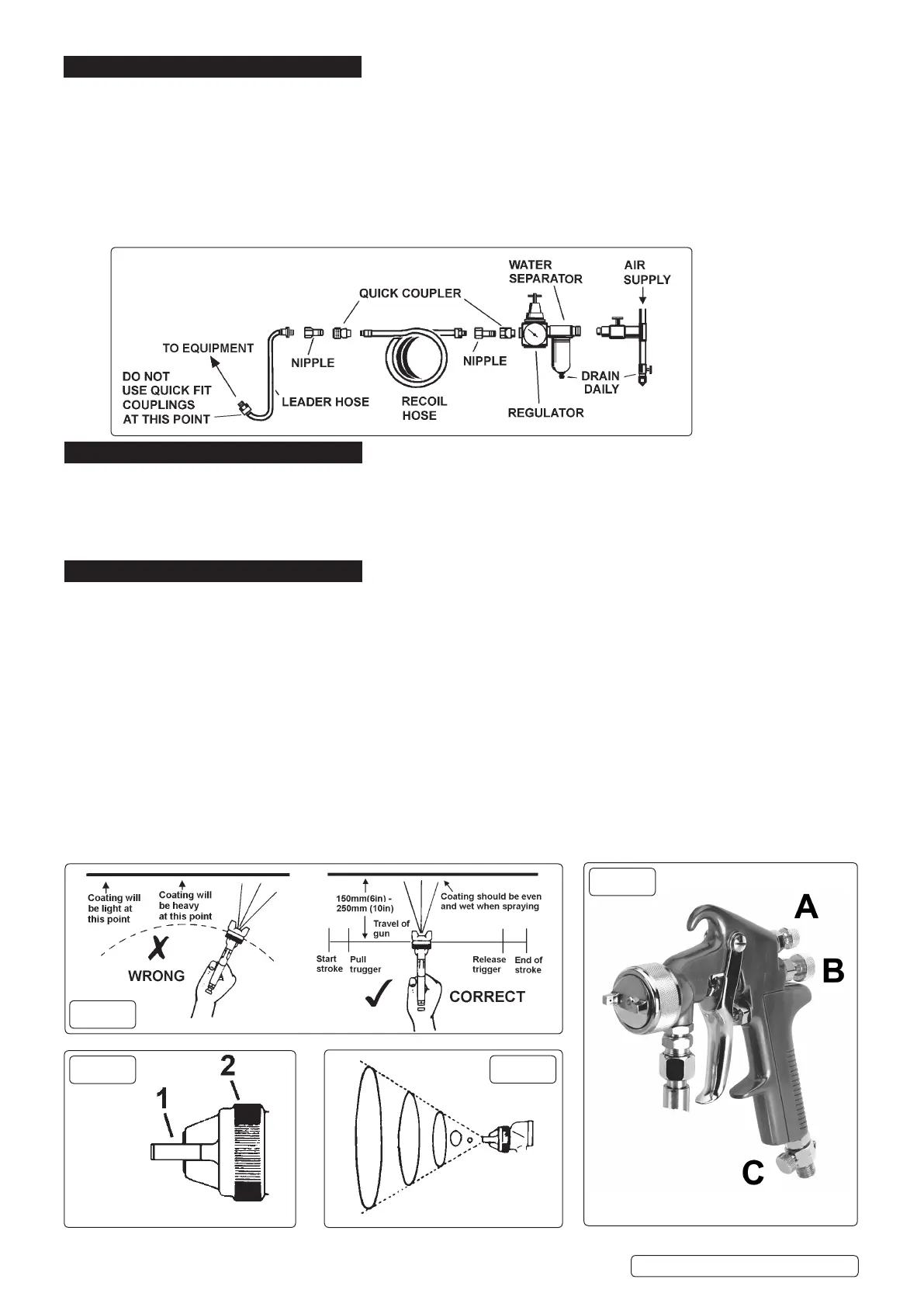

4. AIR SUPPLY

4.1. Ensure that the air valve is in the “off” position before connecting to the air supply.

4.2. The spray gun will require an air pressure of approximately 60psi and an air volume of more than 12cfm.

WARNING! Ensure the air supply is clean does not exceed 90psi. Too high an air pressure and unclean air will shorten

the life of the gun due to excessive wear and may be dangerous, causing damage and/or personal injury.

4.3. Drain the air supply tank daily. Water in the air line will damage the gun and contaminate the paint.

4.4. Clean the compressor air inlet filter weekly. For recommended hook-up, see diagram.

4.5. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres). The minimum hose bore should

be 10mm and fittings must have the same inside dimensions.

4.6. Keep hose away from heat, oil and sharp edges. Check hoses for wear, and make certain that all connections are secure.

S775 | Issue 3 (H,F) 27/11/18

Original Language Version

© Jack Sealey Limited

5. PREPERATION

5.1. The gun was treated with an anti-corrosion agent to protect it prior to first use. Before first use make sure that the gun is flushed

with paint solvent to remove the agent.

WARNING! Solvents and cleaning agents based on halogenated hydrocarbons, e.g. 1.1.1-trichlorethylene and methylene chloride, may

have a chemical reaction with the aluminium components of the gun. In extreme cases the reaction can be explosive. Therefore, use

only solvents/cleaning agents which DO NOT contain these substances.

6. OPERATION

Ensure that you have read and understood the safety instructions in Section 1 and the warning in Section 4.

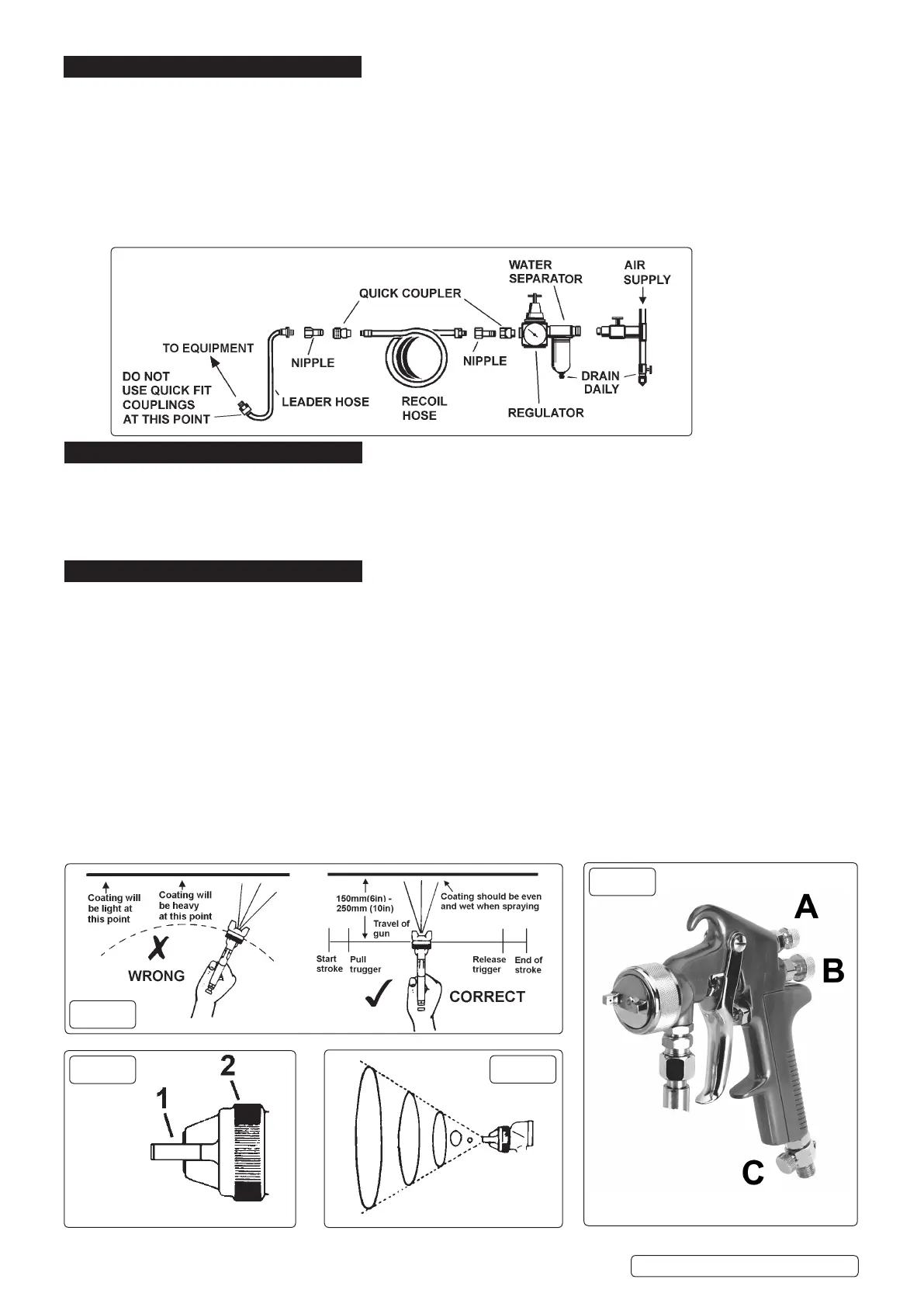

6.1. For best results the gun must be handled and operated correctly. It should be held perpendicular to the surface being sprayed and

moved parallel to it. Start the stroke before squeezing the trigger and release the trigger before finishing the stroke. This will enable you

to accurately control the gun and paint (fig.1).

6.2. Spray from a distance of about 6 to 10 inches depending on the material and the atomizing pressure. The paint deposited should

always be even and wet. Each stroke must overlap the preceding stroke to obtain a uniform finish. To reduce over-spray and obtain

maximum efficiency, spray with the lowest effective atomizing air pressure.

6.3 Controlling the fan spray and the paint:

a) Use the paint control knob (fig.2.B) to increase or decrease the paint flow.

b) The air input control (fig.2.C) should be set to the lowest effective flow.

c) Turn the air cap (fig.3.1) to achieve a horizontal or vertical fan spray. Lock the cap with retaining ring (fig.3.2).

d) The spray pattern is variable from round to flat with all patterns in between, controlled by the pattern knob (fig.2.A).

e) In normal operation, the wings on the cap are horizontal as (fig.3). This provides a vertical fan-shaped pattern (fig.4) which gives

optimum coverage when moving the gun back and forth, parallel to the work surface.

g.1

g.2

g.3

g.4

Loading...

Loading...