7D** Technical Instruction

No.2

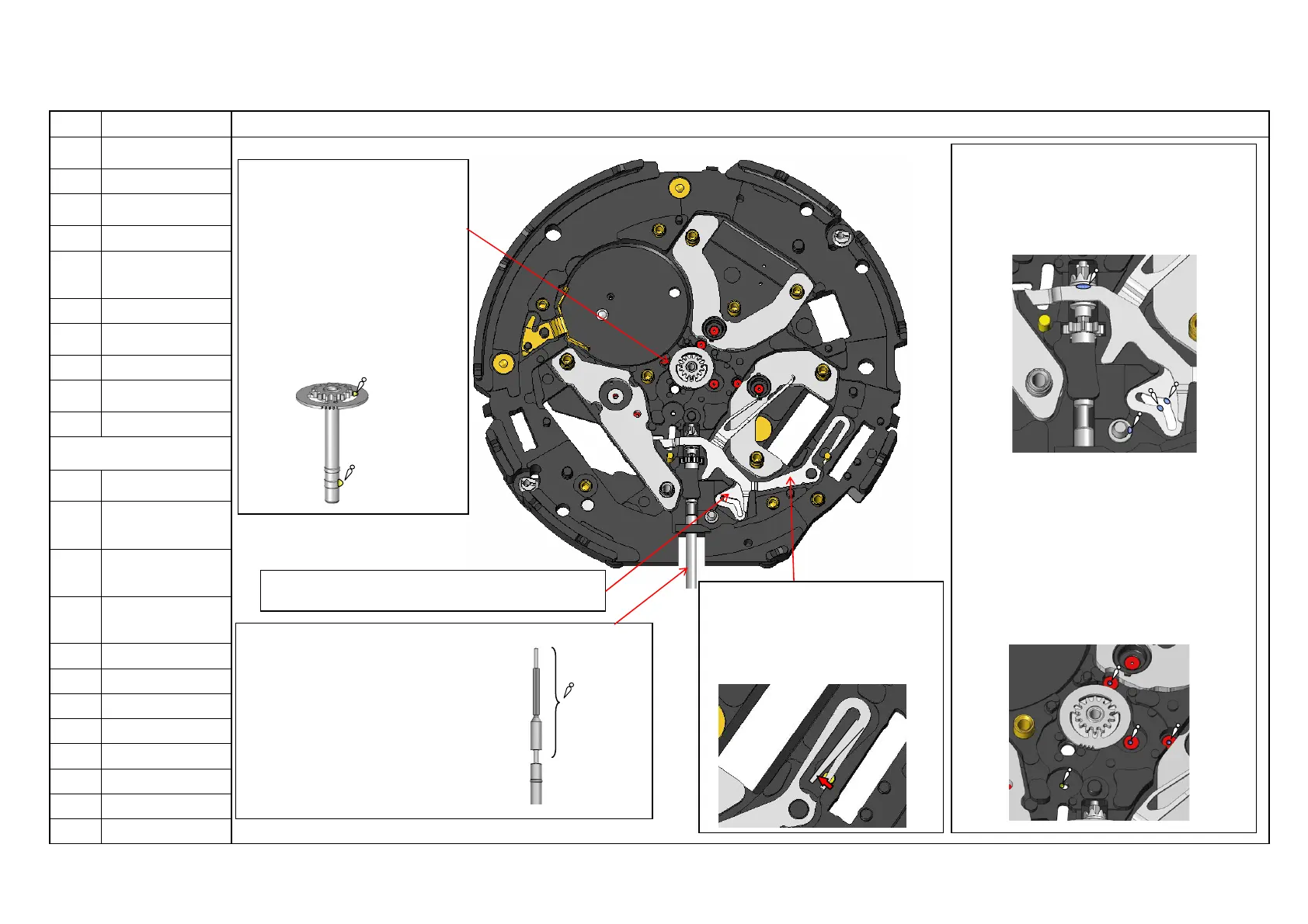

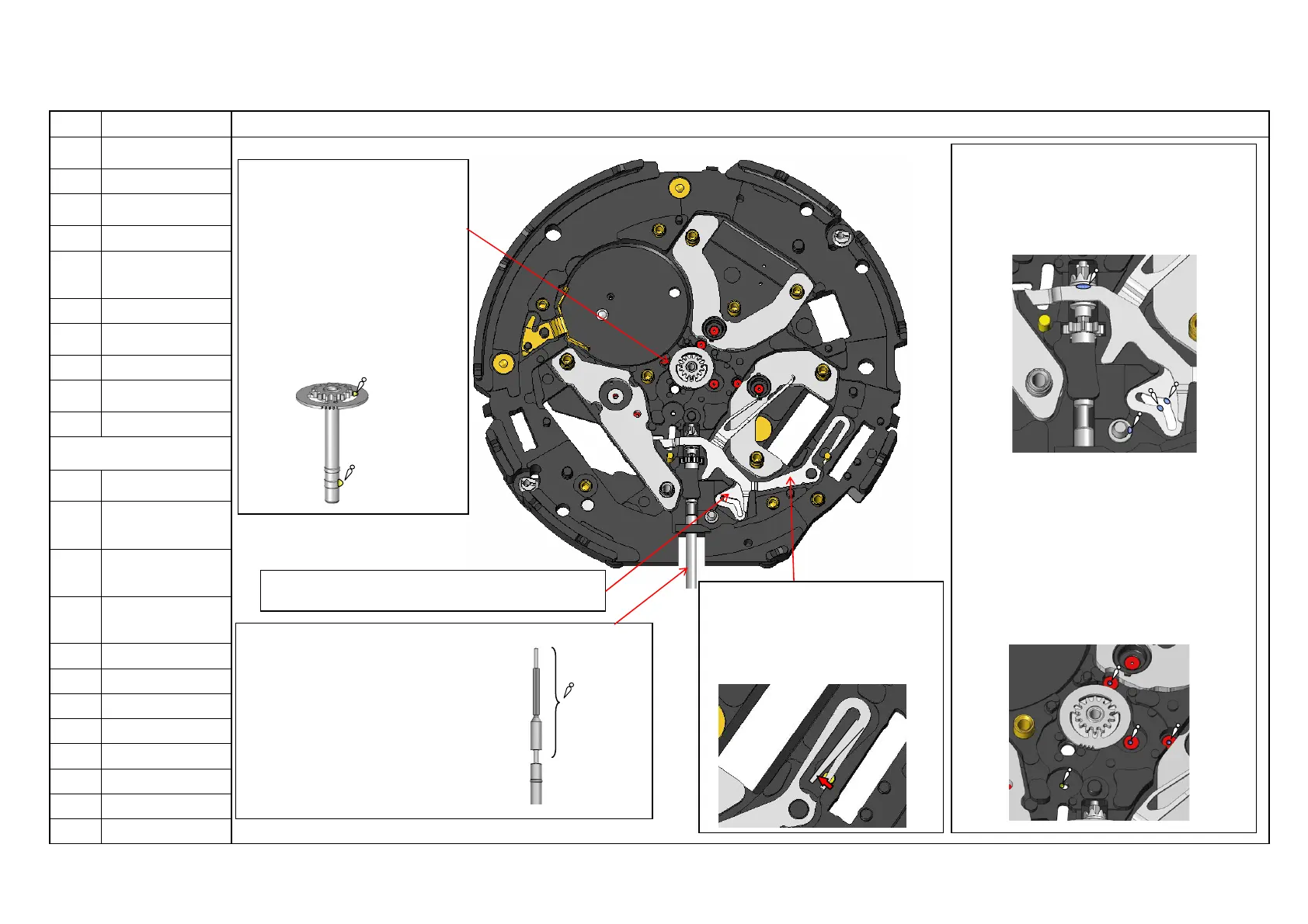

No. PROSESS ILLUSTRATIONS AND SPECIAL INSTRUCTIONS

Assembling the

switching unit

83

Set and lubricate

the winding stem.

↓

82

Set and lubricate

the center wheel &

pinion.

↓

81

Set the train wheel

setting lever.

↓

80

Set the yoke and

hook the arm of it.

↓

Lubricating points of the

switching unit-1

-Stem of the setting

lever

-Point of contact

between the yoke

and clutch wheel

-Lower pivots of the

wheels

(4#, 3#, 50#, 75#)

-Guiding slit of the

train wheel setting

lever

Lubricating points of the switching unit-1

1. Point of contact between the yoke and

clutch wheel

*Type of oil, oil quantity: A0-3III-1 (To prevent

parts from wearing)

2. Axes of the setting lever

*Type of oil, oil quantity: A0-3II-1

(To prevent parts from wearing)

3. Guiding slit of the train wheel setting lever

*Type of oil, oil quantity: A0-3I-2

(To prevent parts from wearing)

4. Lower pivots of the wheels

(4#, 3#, 50#, 75#)

*Type of oil, oil quantity: A0-3II-1

(To maintain good performance)

<81> Set the train wheel setting lever.

<83> Set and lubricate the winding stem.

*Type of oil, oil quantity: A0-3 Lubricate the

entire profile of the winding stem.

(To prevent parts from wearing)

*Securely install the winding stem, giving

it gentle rotations so that the flat face of

the winding stem will be engaged with

both the clutch wheel and the 1st

intermediate wheel for calendar corrector.

<82> Set and lubricate the center

wheel & pinion.

* Lubricating point: convex part

(Refer to the illustration below.)

*Type of oil, oil quantity: A0-3II-1

(To prevent parts from wearing)

*Lubricating point: inner edge of

the ring (Refer to the illustration

below.)

*Type of oil, oil quantity: A0-3II-1

(To prevent parts from wearing)

<80> Set the yoke and hook the

arm of it.

Securely set the arm of the yoke

inside the pin, taking care not to

deform or damage the yoke.

1

3

2

4#

3#

75#

50#

Lubricating

area

Loading...

Loading...