7D** Technical Instruction

No.6

No. PROSESS ILLUSTRATIONS AND SPECIAL INSTRUCTIONS

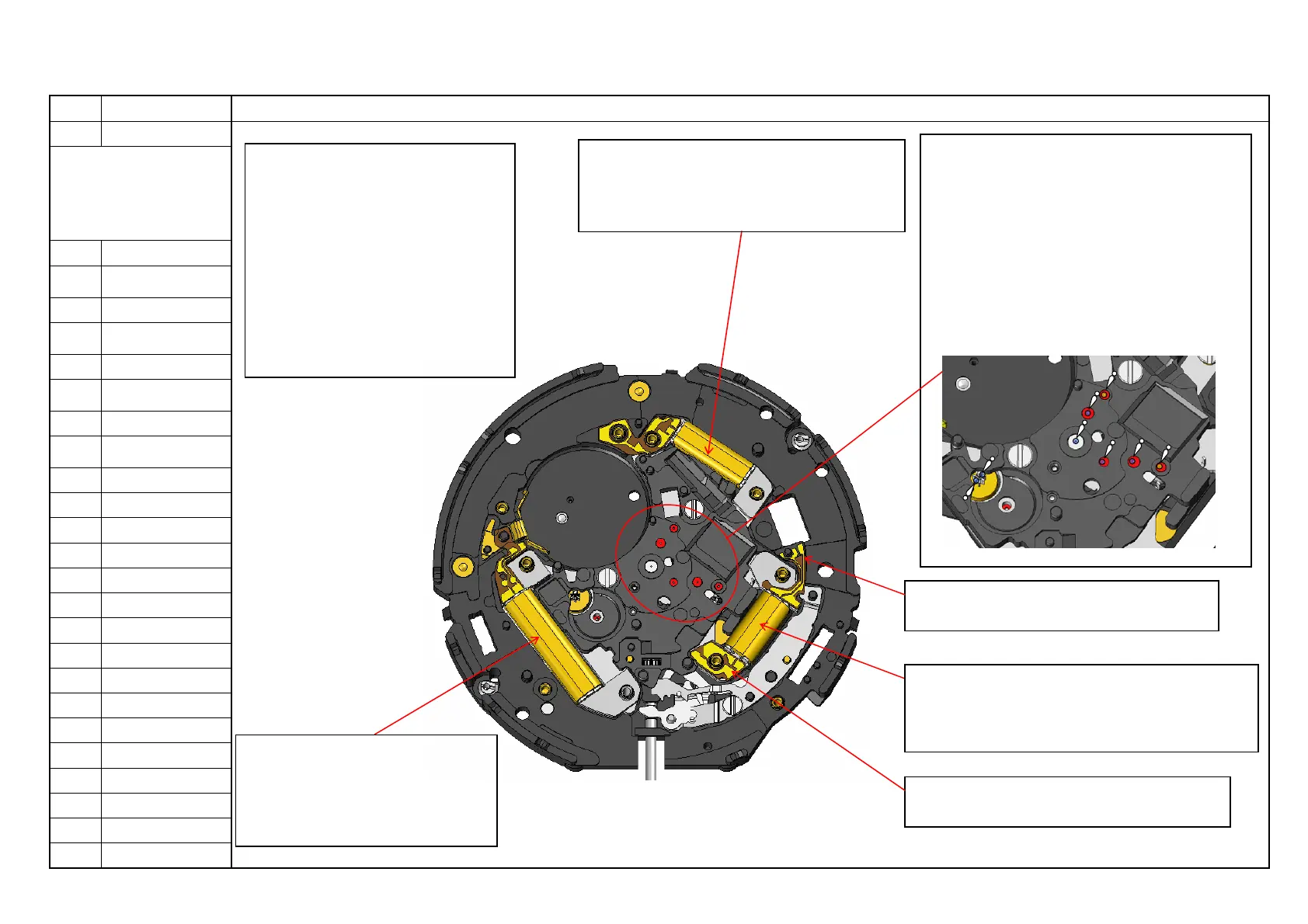

Lubricate the upper pivots

of the wheels.

(5#, 76#, 4#, 3#, 74#, 75#,

Tips of the teeth of the

pinion of generating rotor

66#)

↓

63

Set the hour and

minute coil block.

↓

62

Set the second coil

block.

↓

61

Set the generating

coil block.

↓

Check each coil

block resistance.

Lubricate the upper pivots of the wheels.

5#, 76#

*Type of oil, oil quantity: A0-2II-1

(To maintain good performance)

◆4#, 3#, 74#, 75#

*Type of oil, oil quantity: A0-3II-1

(To maintain good performance)

◆Tips of the teeth of the pinion of the generating

rotor (66#)

*Type of oil, oil quantity: A0-3II-2

(To prevent parts from wearing)

<62> Set the second coil block.

*When mounting the second coil block, take care

not to deform or deform the coil block core.

(To prevent deterioration of the motor)

<61> Set the generating coil block.

*When mounting the generating coil

block, take care not to deform or

deform the coil block core. (To prevent

deterioration of the motor)

<63> Set the hour and minute coil block.

*When mounting the hour and minute coil block, take

care not to distort or deform the coil block core.

(To prevent deterioration of the motor)

5#

4#

3#

76#

75#

74#

66#

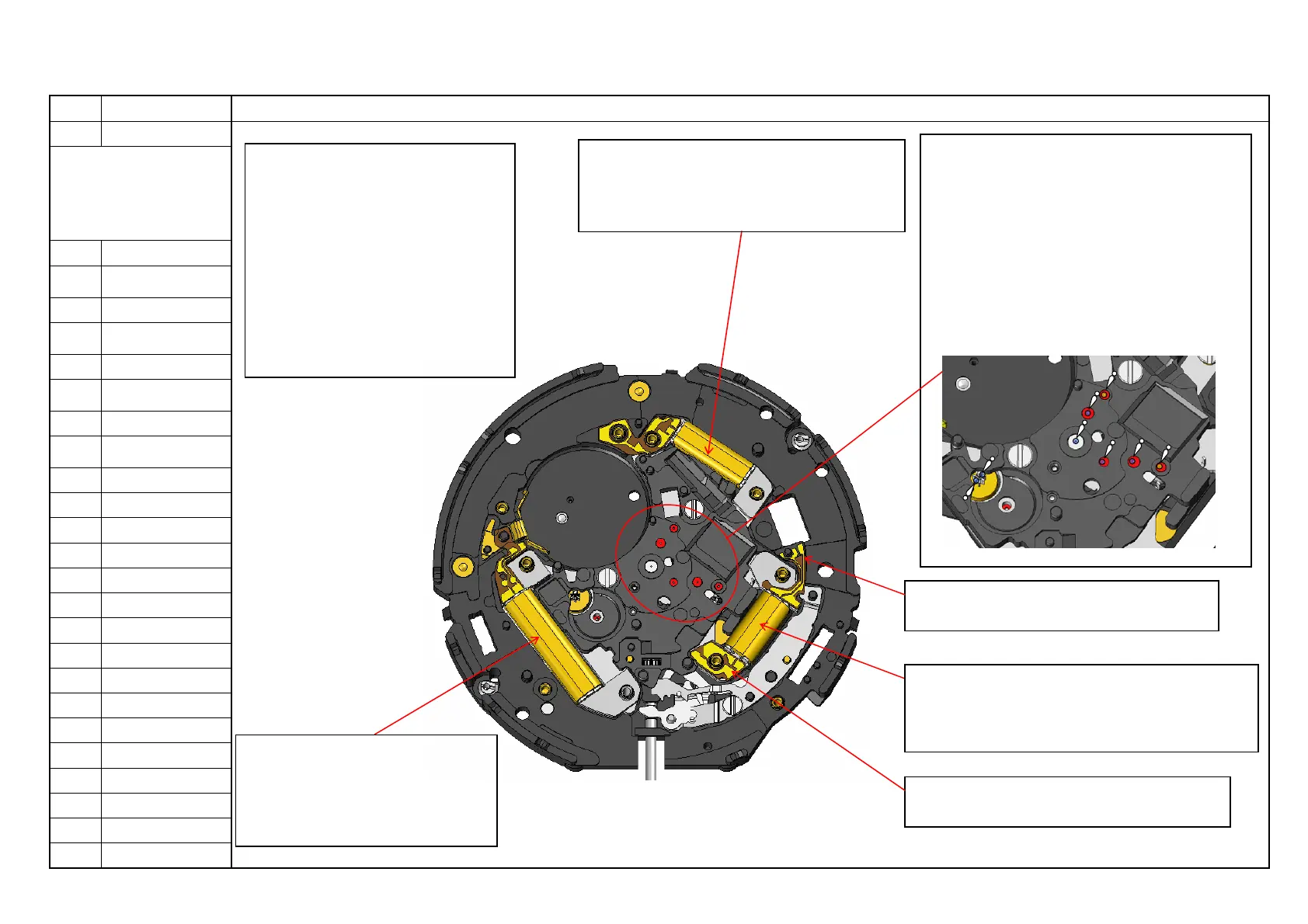

Check each coil block resistance.

*Measure the coil block resistance after

securely installing each coil block to the

movement.

Hour and minute coil block

Coil block for driving: 1.00kΩ–1.25kΩ

Coil block for detection: 270Ω– 330Ω

Second coil block

2.00kΩ – 2.45kΩ

Generating coil block

360Ω – 420Ω

Pattern for checking the coil for detection

Pattern for checking the coil for driving

Loading...

Loading...