-“Clutch Setup” is to provide motor and pump rotational axis over in straight line If

TKF-K/MKF/TAP type motors are ordered with motor and frame, necessary clutch

adjustments are made in our factory. However, adjustment can have failure during

carrying, storage and installation. Make a clutch adjustment discarding the

adjustment made in our factory.

- Two pieces of suitable length of smooth sided template, or steel ruler and a precise

caliper is necessary for clutch setup. (More precise tools should be used for more

precise adjustment)

- Two types of failure may occur during adjustment

a) Angular Failure

b) Parallel Shifting failure

- Distance between two parts of clutch are mutually measured in vertical and

horizontal plane

- Distance which were measured between those four points should be equal.

- A smooth edged template is pressed parallel with one part of clutch and position of

template with respect to other part is observed. Template should contact with both

parts same time and with whole edge.

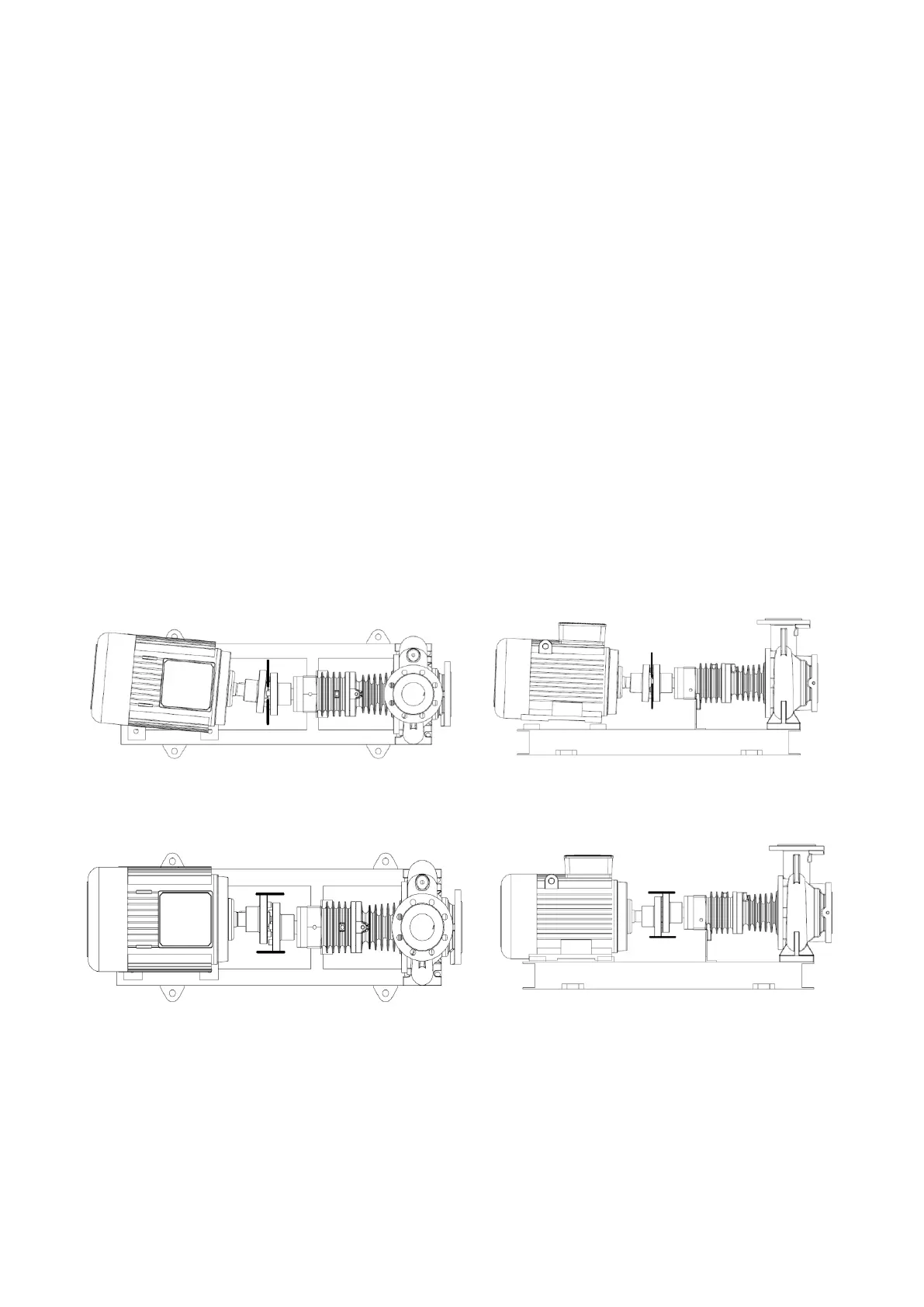

(Figure 3-1) Angle Error in Horizontal Plane (Figure 3-2) Angle Error in Vertical Plane

9

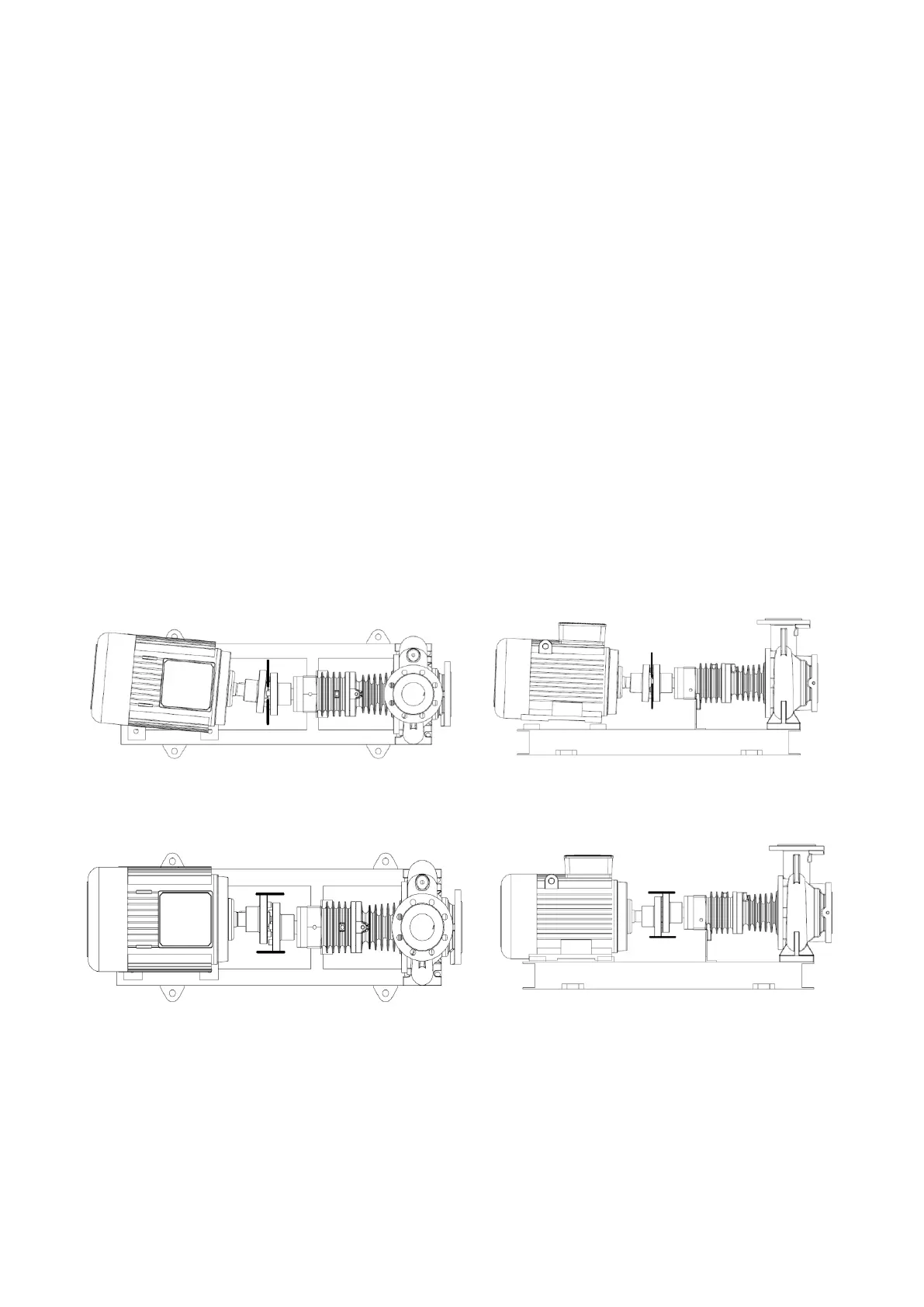

(Figure 3-3) Parallel Sliding Error

in Horizontal Plane

(Figure 3-4) Parallel Sliding Error

in Vertical Plane

Loading...

Loading...