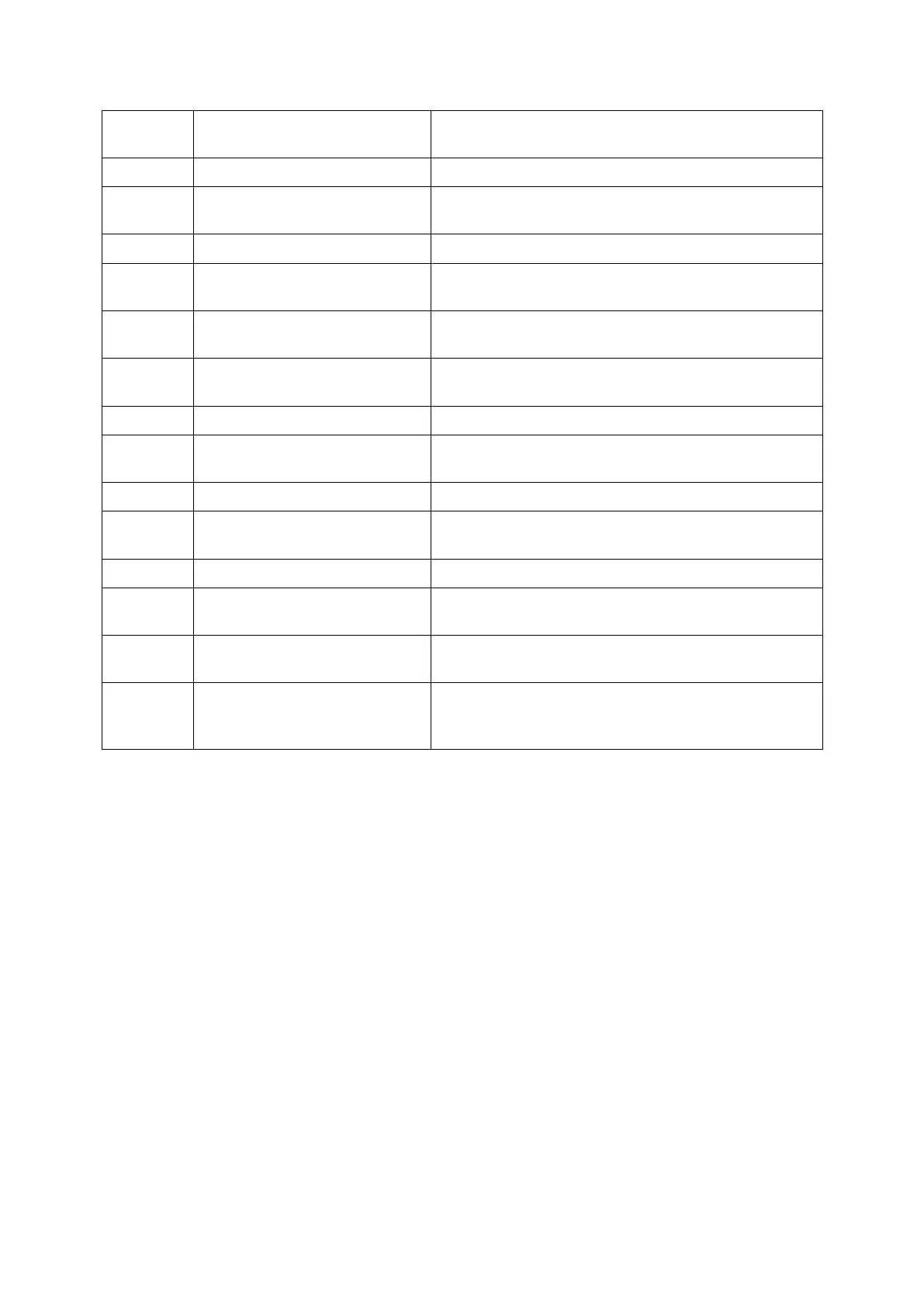

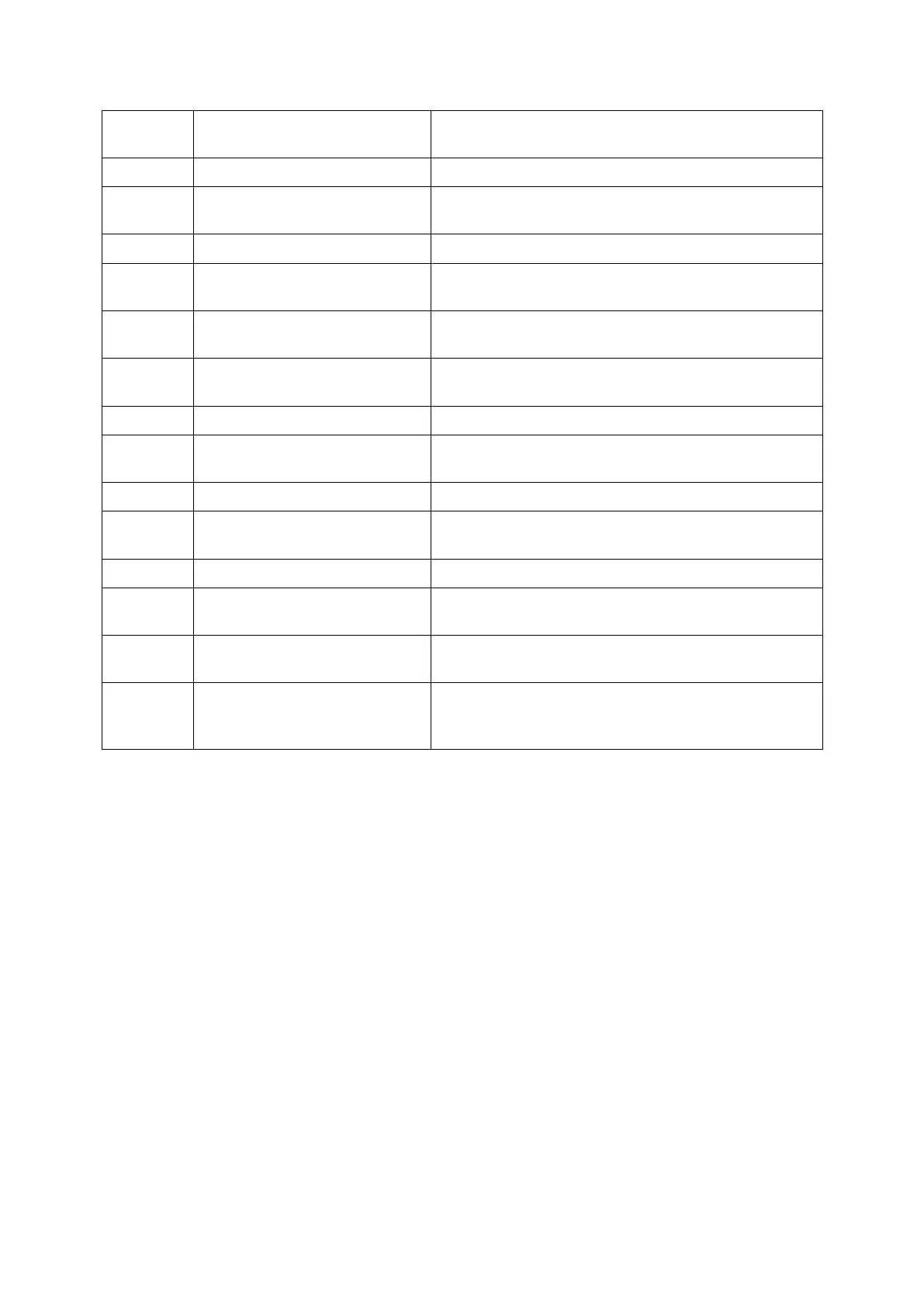

Impellor, check valve or filter

clogged

Clean Impellor, check valve or filter

Impellor, partially filter clogged

Clean Impellor, or filter

Mechanical friction in pump

Check whether there are any obstacle or bend in

pump rotor

Soft seals are over tightened

Worn or malfunctioned

impellor

Bearing covers are over

tightened.

Check the covers and make necessary corrections

Flow rate is less than pumps

necessary flow rate

Increase the flow rate, use by pass valve or line if

necessary

Clutch adjustment is broken

Check the clutch rubber and adjust again

There is so much grease in

bearing

Imbalanced rotating parts

Adjust the balance of rotating parts

Pump operates out of its

operation region

Check the operational region values

Check the shaft and replace if necessary

Insufficient lubrication or

lubricant is dirty

Check the amount of lubricant, clean bearing bed

and capsules and grease again

Check the motor,. Motor is not suitable for its air

conditioning position

Density or viscosity of

discharged liquid is more than

given value

Use motor having greater power

Table 4

22

Loading...

Loading...