EN - 16 WWW.SENIXTOOLS.COM

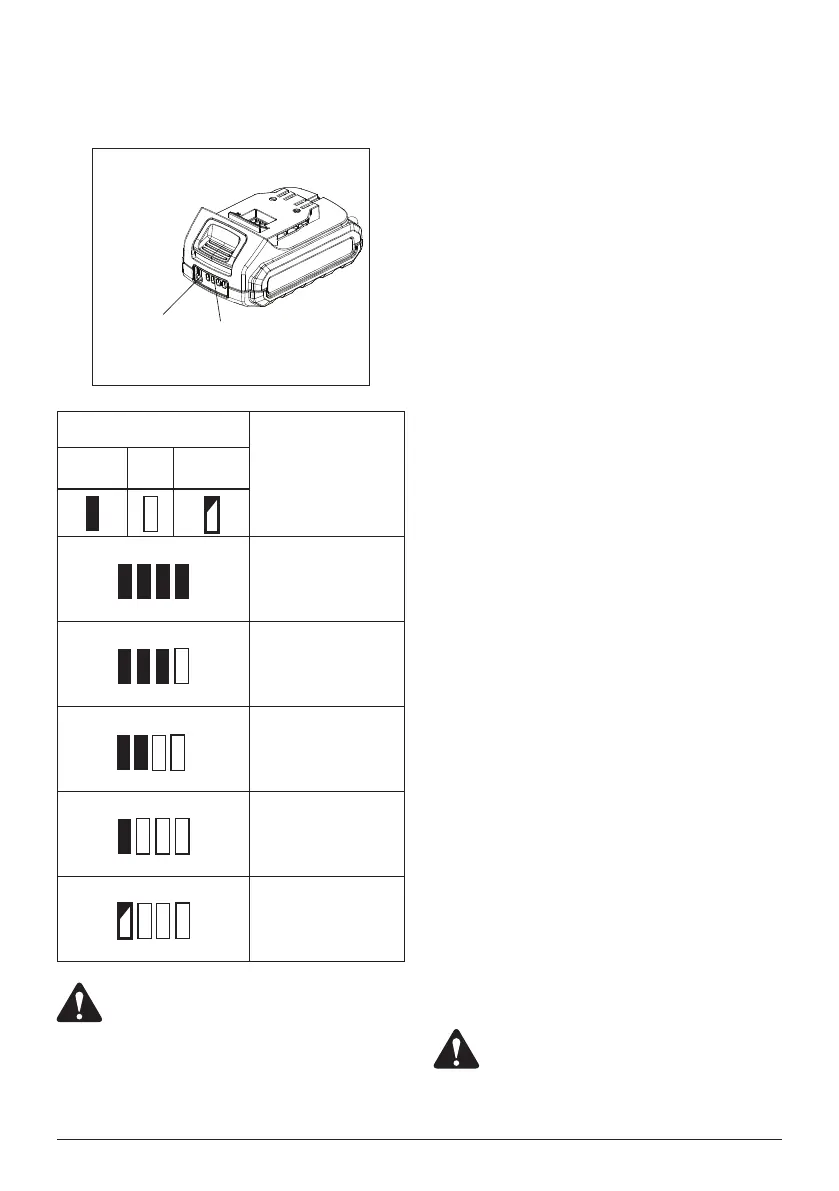

CHARGING INDICATOR

Press the light button on the battery pack to check whether

it needs to charge.

Light Button

Indicator

Lights

Status

Lighted Off Blinking

The battery is at full

capacity.

The battery is at 75%

capacity.

The battery is at 50%

capacity and requires

charging.

The battery is at 25%

capacity and requires

charging soon.

The battery is less than

5% capacity and requires

charging immediately.

WARNING:

Malfunctions may occur when the four lights

blinking in turns.

OVERHEAT PROTECTION

When the tool/battery is overheated, the tool stops

automatically. In this situation, let the power tool/battery cool

before turning the tool on again.

OVERDISCHARGE PROTECTION

When the battery capacity is not enough, the tool stops

automatically. In this case, remove the battery from the tool

and charge the battery.

WORKPIECE AND WORK AREA

SET UP

1. Designate a work area that is clean and well lit. The

work area must not allow access by children or pets to

prevent distraction and injury.

2. Secure loose workpieces using a vise or clamps (not

included) to prevent movement while working.

3. There must not be objects, such as utility lines,nearby

that will present a hazard while working.

PRACTICAL ADVICES

1. Ensure that correct application tool is tted and all

controls are set in correction position.

2. Always hold the product perpendicular to the workpiece.

Holding it at an angle may cause slipping, jamming or

damage of application tool, screw/bolt and workpiece.

3. Always place the application tool in position before

switching the product on.

4. Start with low speed until the screw penetrates

workpiece perpendicularly or bolt is tted along the

thread properly.

5. Before screwing larger, longer screws into hard

materials, it is advisable to pre-drill a pilot hole with the

core diameter of the thread to the entire screw length.

6. Apply proper feeding force to keep the connect of bit/

socket and screw/bolt/nut. Too big feeding force will not

increase working effectiveness but increase the risk of

loss of control and heating of screw/bolt.

7. If the screw/bolt gets stuck in the workpiece, switch

the power tool off, switch to reverse rotation mode and

press the switch trigger slightly to loosen the screw/bolt.

8. Check the application tool regularly during work. Ret or

replace it if necessary.

WARNING:

Do not use the power tool like a hand screw

driver or wrench, this could damage the spindle

lock in the power tool.

Loading...

Loading...