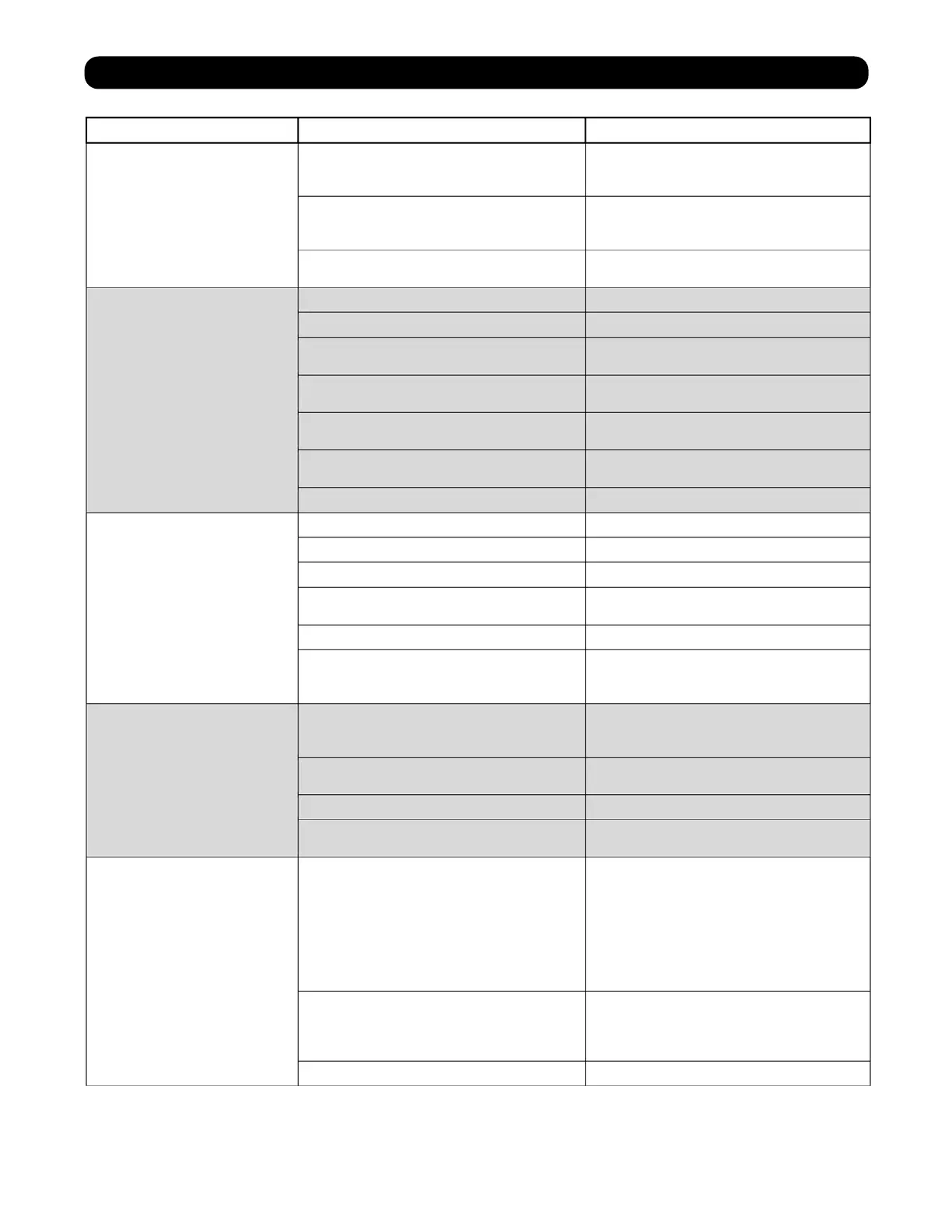

Residual salt in service lines

Low water pressure

Check incoming water pressure. Water

pressure must remain at minimum of 40

Incorrect injector size

Replace Injector with correct size for the

application. Refer to System Specification

Restricted drain line

Check drain line for restrictions or debris

and clean

Excessive water in Brine Tank

Improper program settings Check refill setting

Plugged Injector Remove Injector and clean or replace

Drive cap assembly not tightened in

properly

Re-tighten the drive cap assembly

Damaged Seal and Spacer Stack

Assembly

Replace Seal and Spacer Stack Assembly

Restricted or kinked drain line

Check drain line for restrictions or debris

and or un-kink drain line

Plugged backwash flow controller

Remove backwash flow controller and

Missing Refill Flow Controller Replace Refill Flow Controller

Control Valve fails to draw

brine

Injector is plugged Remove Injector and clean or replace

Faulty Brine Piston Replace Brine Piston

Brine line tubing connection leak Inspect Tubing and Fittings for air leak

Drain line restriction or debris can cause

excess back pressure on Injector

Inspect drain line and clean to correct

Drain line too long or elevated too high Shorten length and or height

Low water pressure

Check incoming water pressure. Water

pressure must remain at minimum of 40

Water running to drain

Power outage during regeneration

Upon power being restored Control Valve

will finish the remaining regeneration time.

Damaged Seal and Spacer Stack

Assembly

Replace Seal and Spacer Stack Assembly

Piston assembly failure Replace Piston Assembly

Drive Cap Assembly not tightened in

properly

Re-tighten the Drive Cap Assembly

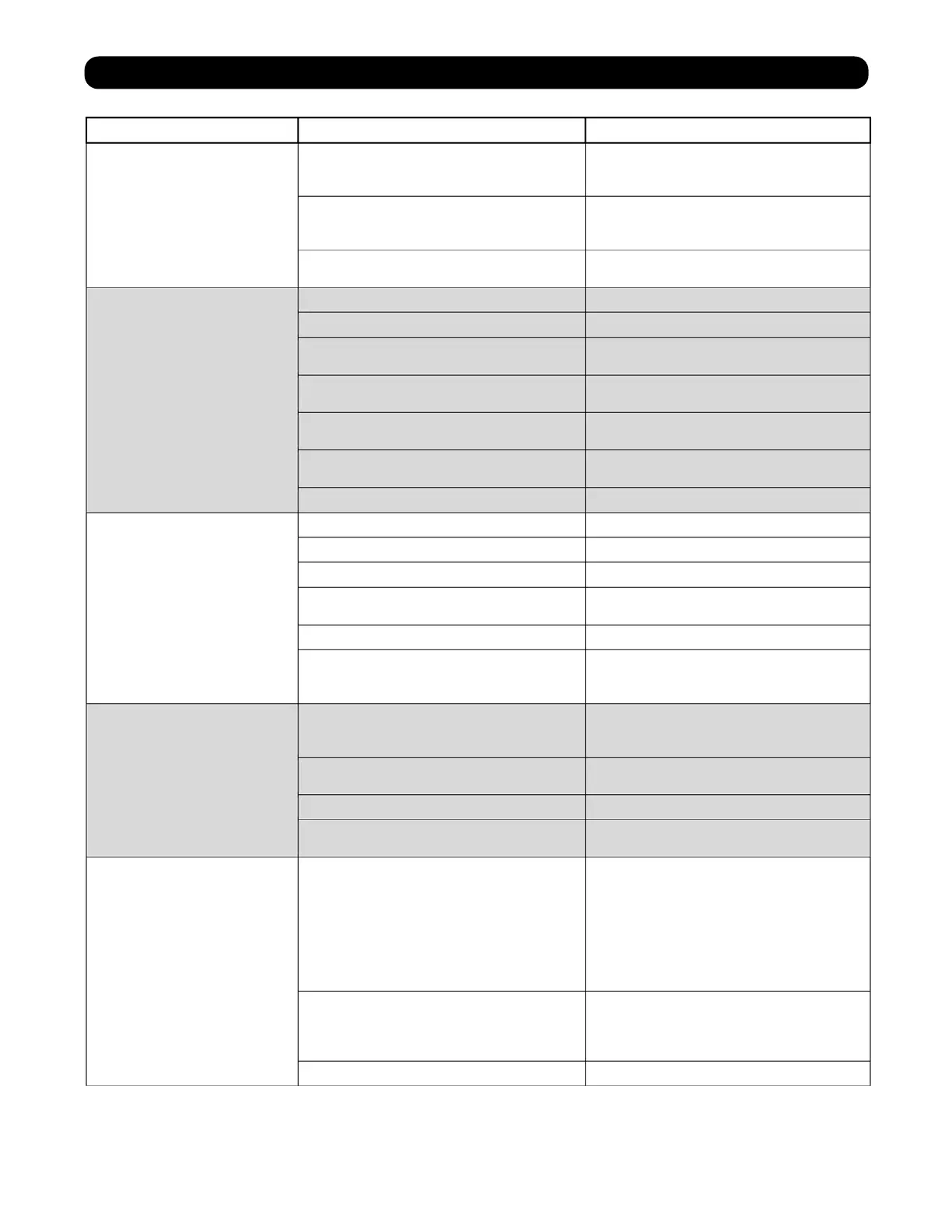

Err - 1001 = Control unable to

sense motor movement

Motor not inserted full to engage pinion,

motor wires broken or disconnected

Disconnect power, make sure motor is

fully engaged, check for broken wires,

make sure two pin connector on motor is

connected to the two pin connection on the

Circuit Board labeled MOTOR. Press

NEXT and REGEN buttons at the same

time for 3 seconds to resynchronize

Circuit Board not properly snapped into

drive bracket

Properly snap Circuit Board into drive

bracket and then Press NEXT and REGEN

buttons at the same time for 3 seconds to

resynchronize software with piston.

Missing reduction gears Replace missing gears

Control Valve Trouble Shooting

Loading...

Loading...