Installation, Operation, Maintenance

Instructions for Severn Glocon

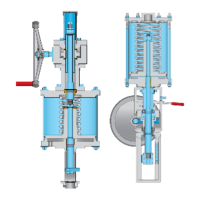

Piston Actuators – P Series

Typical Piston Actuator –List of Parts

Top and Side

Mount Handwheel

override options

shown above

General Inspection of parts

General inspection is for visual actuator condition only and a

test to confirm smooth movement of the piston in operation.

Advanced maintenance items:

Actuator ‘O’ ring seals, wiper ring and Piston rod guides

(Soft parts are available as an actuator repair kit)

Advanced Inspection – (to be carried out by trained /

experienced personnel only)

ACTUATOR ‘O’RING SEAL’S - Not re-useable

ACTUATOR SPRING – If damaged contact Severn Glocon

for advice on repair or whether replacement is needed

PISTON ROD GUIDES - Examine general condition; renew

if necessary

USE OF THIS MANUAL, LEGAL DIRECTIVES,

ENVIRONMENTAL AND OTHER SAFETY NOTICES

This manual to be read in conjunction with Severn Glocon

“Supplementary Installation, Erection, Maintenance and

Operating Procedures” document number SGG-IOM-5000,

DS610 and any other related O & M instructions relating to

any accessories fitted to the Control Valve. All notices,

warnings and guidance given in that manual are also

applicable to this document.

INTENDED USE

Reference is to be made to the Control Valve Specification

Sheet, Installation and Operation Instructions, nameplate to

check product is suitable for the intended use / application.

See Installation, Operation and Maintenance Instructions for

Severn Glocon Control and Choke valves SGG-IOM-5000-

M01-REV02 for information on the following (Latest Ed.’s):

a) MACHINERY DIRECTIVE INCORPORATED INTO A

MACHINE

b) ATEX DIRECTIVE

c) PRESSURE EQUIPMENT DIRECTIVE PED

d) ENVIROMENTAL and OTHER LEGISLATION & IPPC

DIRECTIVE

e) RETURNING PRODUCTS

DISPOSAL

Unless otherwise stated in the Instructions, this product is

recyclable and no ecological hazard is anticipated with its

disposal providing due care is taken

If any doubts exist, contact SEVERN GLOCON LTD

quoting the valve serial number

Safety: Always ensure safe working practices are followed:

Always isolate valve before maintenance.

Always use lockout methods to ensure safety

Caution: Do not put hands inside yoke area

Always use correct tools. Do not over tighten.

Do not use extension bars to force movement

Poison risk: Do not incinerate PTFE. Do not

smoke whilst handling PTFE.

Always read the manual. If any doubts exist,

contact SEVERN GLOCON LTD quoting the

valve serial number.

WARNING: When ordered, the actuator and or control valve

configuration and materials of construction are selected to

meet particular pressure, temperature, pressure drop and

controlled fluid conditions. Personal injury, property

damage, equipment damage, or leakage due to escaping

gas or bursting of pressure containing parts may result if the

actuator and or control valve or its ancillaries are over

pressured or installed where service conditions exceed the

actuator and control valve design limits. To avoid such injury

or damage, provide a relief valve for overpressure protection

as required by accepted industry or local codes and good

engineering practice. Do not apply other conditions to the

valve without written approval from Severn Glocon.

WARNING: Before performing any maintenance operation:

Isolate the actuator and or control valve from process

pressure. Relieve process pressure from both sides of the

control valve. Drain the process media from both sides of

the valve. If the control valve is to be removed from the line

decontaminate any process fluid remaining in the valve to

make safe. Disconnect and isolate any operating lines

providing air pressure, electric power, or a control signal to

the actuator. Vent the air pressure from the actuator. Be

sure that the actuator cannot suddenly open or close the

valve (Note by disconnecting the air and or power lines the

actuator will move the valve to its power failure position).

Ensure persons are a suitable distance from moving parts.

Use lock out procedures to be certain that the above

measures stay in effect whilst work is carried out on the

actuator or control valve.

Scope of this Manual - Installation - General

This manual includes installation, operating and

maintenance information for Severn Glocon P Series

actuators only. Please refer to separate manuals for

Loading...

Loading...