- 7 -

TROUBLE SHOOTING

Additional help and information can be found by contacting Tempest.

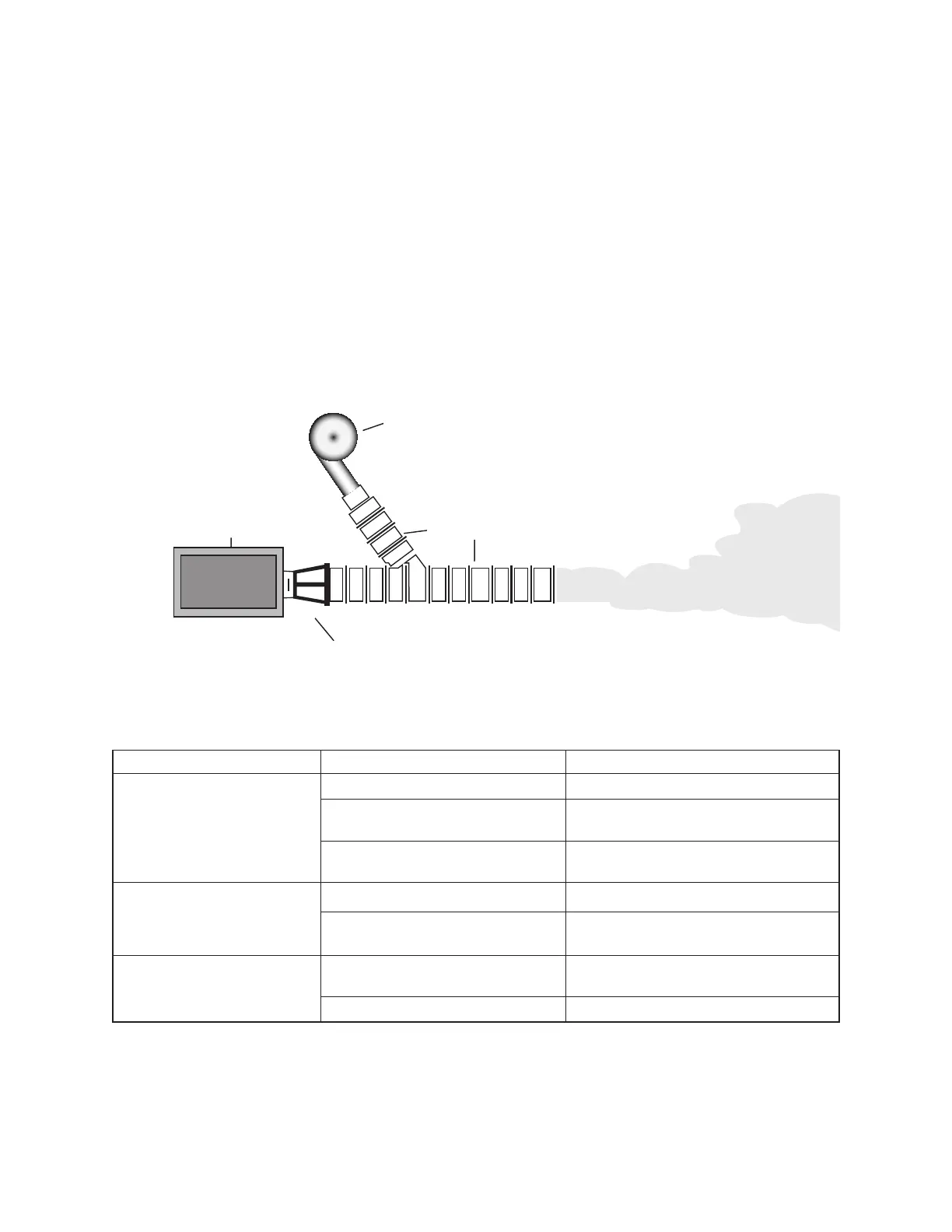

DUCTING FOG

It is often desirable to duct fog from the machine to another location. This can be accomplished using

flexible hose (“dryer hose”) or similar large diameter ducting such as 4in (100mm) PVC. Avoid sharp

bends in the duct, which can create turbulence or back flow.

The duct should be positioned no closer than 2in (50mm) to the nozzle. An open airflow between the

nozzle and opening of the duct is crucial to allow for aerosolization and create proper airflow. Placing

ductwork or tubing directly over the nozzle or nozzle guard will cause damage to the machine and will

void the warranty. Take all precautions to avoid fire hazards as the nozzle is extremely hot.

In some instances, it is desirable to use a fan to accelerate the fog through the ductwork. Never run fog

through the blades of a fan as the action of the impeller will cause condensation of fluid particles. To

properly use a fan, create a vent in the ducting system such as a “branched wye” and introduce a fan at

the vent point. This will create a low pressure point that “pulls or pushes” the fog through the ductwork.

Contact Tempest

for more advice on ducting fog

.

Squirrel Cage Fan

Ducting Hose

Hose Adaptor

Fog Machine

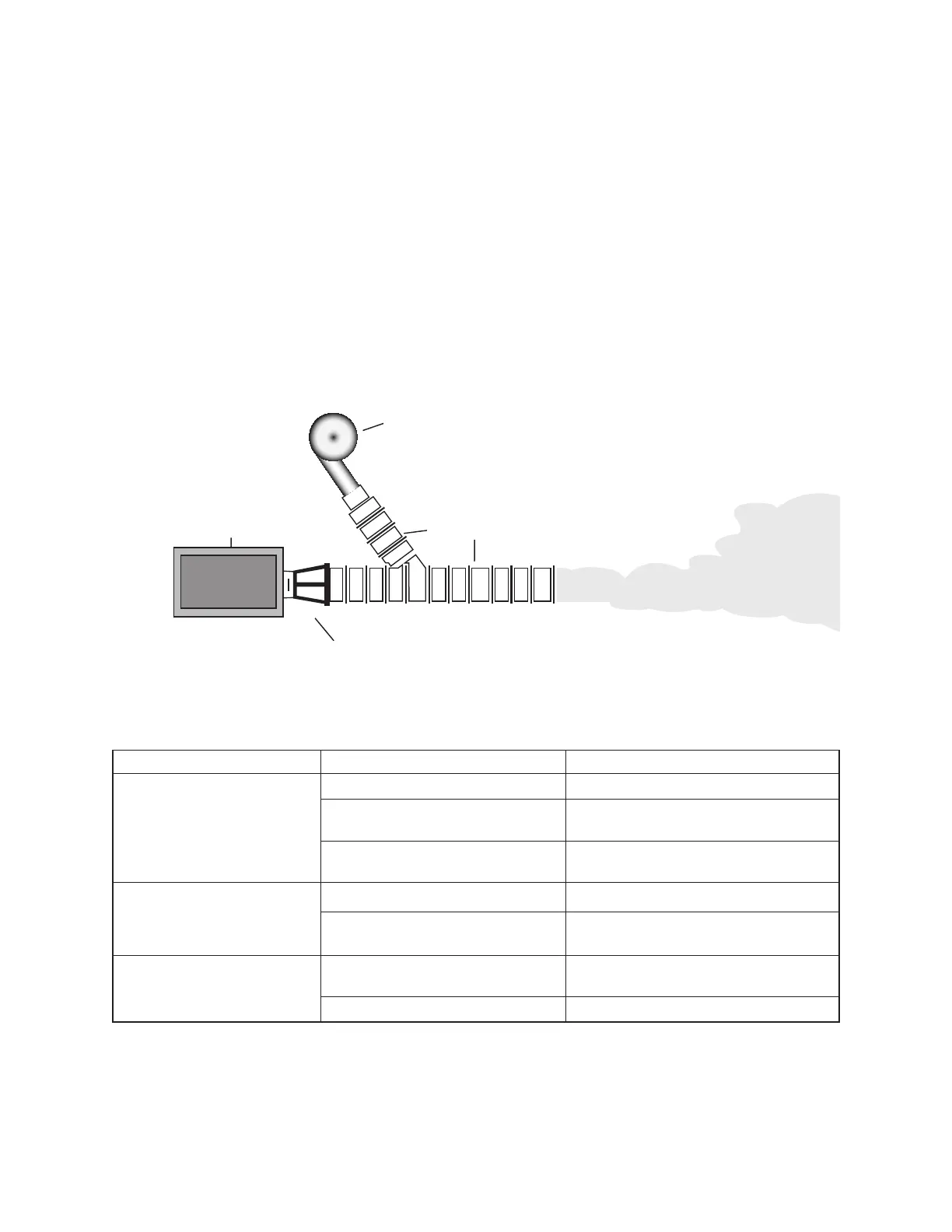

Machine does not heat up

Machine is not turned on

No power at AC cable inlet

Machine has overheated and

internal thermal fuse is blown

Ensure Main Power Switch is on

Check to make sure machine is plugged in

properly. Check the circuit breaker.

Contact nearest Service Center for repair

Machine does not produce fog

when the Fog Switch on the

remote control is pressed

Ensure Main Power Switch is on

Machine not turned on

Problem Probable Cause(s) Suggested Remedy

Fog output is weak

Machine not at

operating temperature

Wait 7-10 minutes until green Ready

Indicator light illuminates on remote

Fluid filter above fluid line

Ensure filter is submerged inside

the bottle

Heat exchanger is clogged

Contact nearest Service Center for repair

Loading...

Loading...