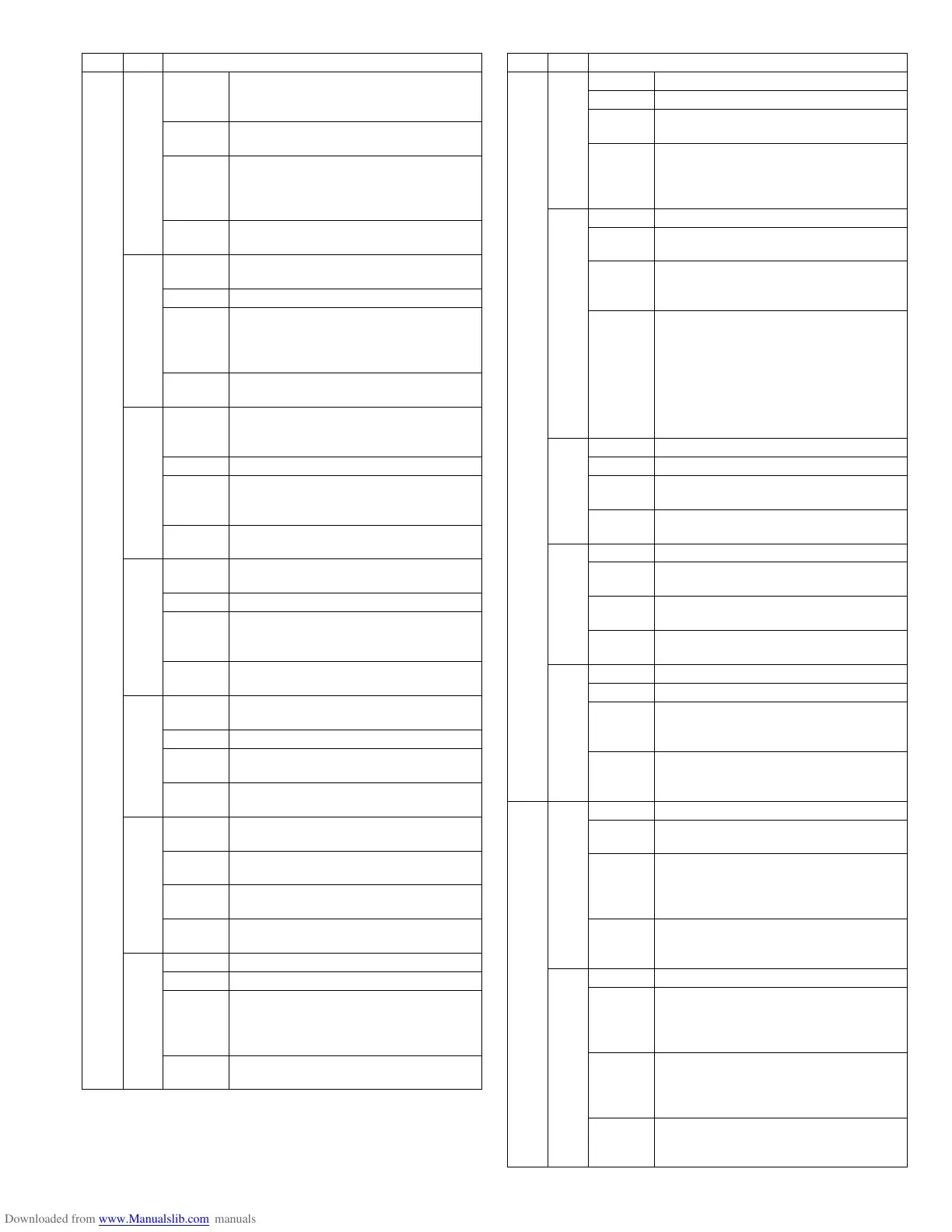

AR-M350 TROUBLE CODES 11-6

F1 33 Content Console finisher (AR-FN7)

punch (AR-PN1) side registration motor

trouble

Detail Punch side registration motor operation

abnormality

Cause Motor lock

Motor rpm abnormality

Overcurrent to the motor

Console finisher control PWB trouble

Check and

remedy

Use DIAG (SIM3-3) to check the motor

operation.

34 Content Console finisher (AR-FN7)

punch (AR-PN1) motor trouble

Detail Punch motor operation abnormality

Cause Motor lock

Motor rpm abnormality

Overcurrent to the motor

Console finisher control PWB trouble

Check and

remedy

Use DIAG (SIM3-3) to check the motor

operation.

35 Content Console finisher (AR-FN7)

punch (AR-PN1) side registration sensor

trouble

Detail Sensor input value abnormality

Cause Sensor breakage

Harness disconnection

Console finisher control PWB trouble

Check and

remedy

Use DIAG (SIM3-2) to check the sensor

operation.

36 Content Console finisher (AR-FN7)

punch (AR-PN1) timing sensor trouble

Detail Sensor input value abnormality

Cause Sensor breakage

Harness disconnection

Console finisher control PWB trouble

Check and

remedy

Use DIAG (SIM3-2) to check the sensor

operation.

37 Content Console finisher (AR-FN7)

backup RAM trouble

Detail Backup RAM contents are disturbed.

Cause Console finisher control PWB trouble

Malfunction by noise

Check and

remedy

Replace the console finisher control PWB.

38 Content Console finisher (AR-FN7)

punch (AR-PN1) backup RAM trouble

Detail Punch unit backup RAM contents are

disturbed.

Cause Punch control PWB trouble

Malfunction by noise

Check and

remedy

Replace the punch control PWB.

81 Content Console finisher transport motor abnormality

Detail Transport motor trouble

Cause Motor lock

Motor rpm abnormality

Overcurrent to the motor

Console finisher control PWB trouble

Check and

remedy

Use DIAG (SIM3-3) to check the motor

operation.

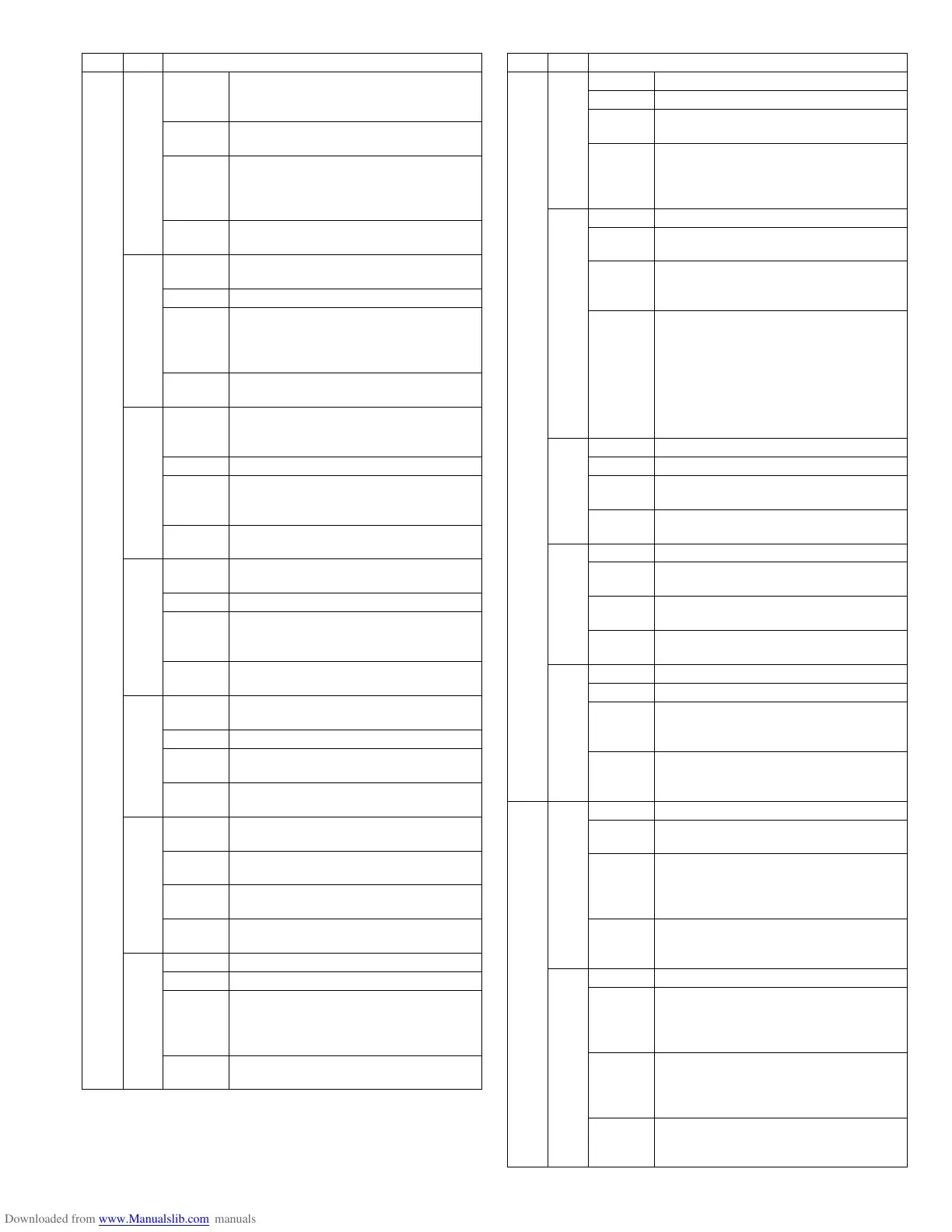

MAIN SUB

F2 00 Content Toner control sensor abnormality

Detail Toner control sensor output open

Cause Connector harness trouble

Connector disconnection

Check and

remedy

Check connection of the toner control sensor.

Check connection of connector and harness

to the main PWB.

Check for disconnection of harness.

02 Content Toner supply abnormality

Detail Toner control sensor output value becomes

under-toner too earlier.

Cause Connector harness trouble

Toner control sensor trouble

The toner cartridge seal is not removed

Check and

remedy

Check connection of the connector in the

toner motor section.

Check connection of connector and harness

to the main PWB.

Check for disconnection of harness.

Toner control sensor output check DIAG

(SIM25-1)

Remove the toner cartridge seal.

04 Content Improper cartridge (life cycle error, etc.)

Detail An improper process cartridge is inserted.

Cause IC chip trouble

Improper cartridge

Check and

remedy

Insert a proper cartridge.

05 Content CRUM error

Detail Communication with IC chip cannot be

made.

Cause IC chip trouble

Improper cartridge

Check and

remedy

Insert a proper cartridge.

39 Content Process thermistor trouble

Detail Process thermistor open

Cause Process thermistor trouble

Process thermistor harness disconnection

PCU PWB trouble

Check and

remedy

Check connection of harness and connector

of the process thermistor.

Check PCU PWB.

F3 12 Content Machine no. 1 tray lift-up trouble

Detail PED does not turn ON in the specified time.

LUD does not turn ON in the specified time.

Cause PED/LUD trouble

No. 1 tray lift-up trouble

Check connection of harness between the

PCVU PWB, lift-up unit, and paper feed unit.

Check and

remedy

Check PED, LUD, and their harness and

connectors.

Check the lift-up unit.

22 Content Multi purpose tray lift-up trouble

Detail MCPED does not turn ON in the specified

time.

MCLUD does not turn ON in the specified

time.

Cause MCPED/MCLUD trouble

Multi purpose tray lift-up motor trouble

Harness disconnection f the PCU PWB, the

lift-up unit, and the paper feed unit.

Check and

remedy

Check MCPED, PCLUD, and their harness

and connectors.

Check the lift-up unit.

MAIN SUB

( !"#

Loading...

Loading...