MX3500N SIMULATION 7 – 57

44-4

Purpose

Setting

Function (Purpose)

Used to perform the correction operation of

the image forming section and to set the

process control sensor adjustment condi-

tions.

Section

Process

Item

Operation

Operation/Procedure

NOTE: Unless a special change is required, set the set values to

the default values.

1) Select the set item with [↑] and [↓] buttons.

The highlighted set value is switched and the value is dis-

played in the setting area.

* If there is any item over [↑], an active display is made and

item is shifted.

If there is no item over [↑], the display grays out and the

operation is invalid.

If there is any item under [↓], an active display is made and

item is shifted.

If there is no item over [↓], the display grays out and the

operation is invalid.

2) Enter the set value with 10-key.

* Press [C] key to clear the entered values.

When setting is completed, [OK] button returns to the normal

display.

3) When [OK] button is pressed, the current set value is saved to

EEPROM and RAM.

* When [↑], [↓], [COLOR], or [BLACK] key is pressed, the cur-

rent set value is saved to EEPROM and RAM.

<Set range and default value of each setup>

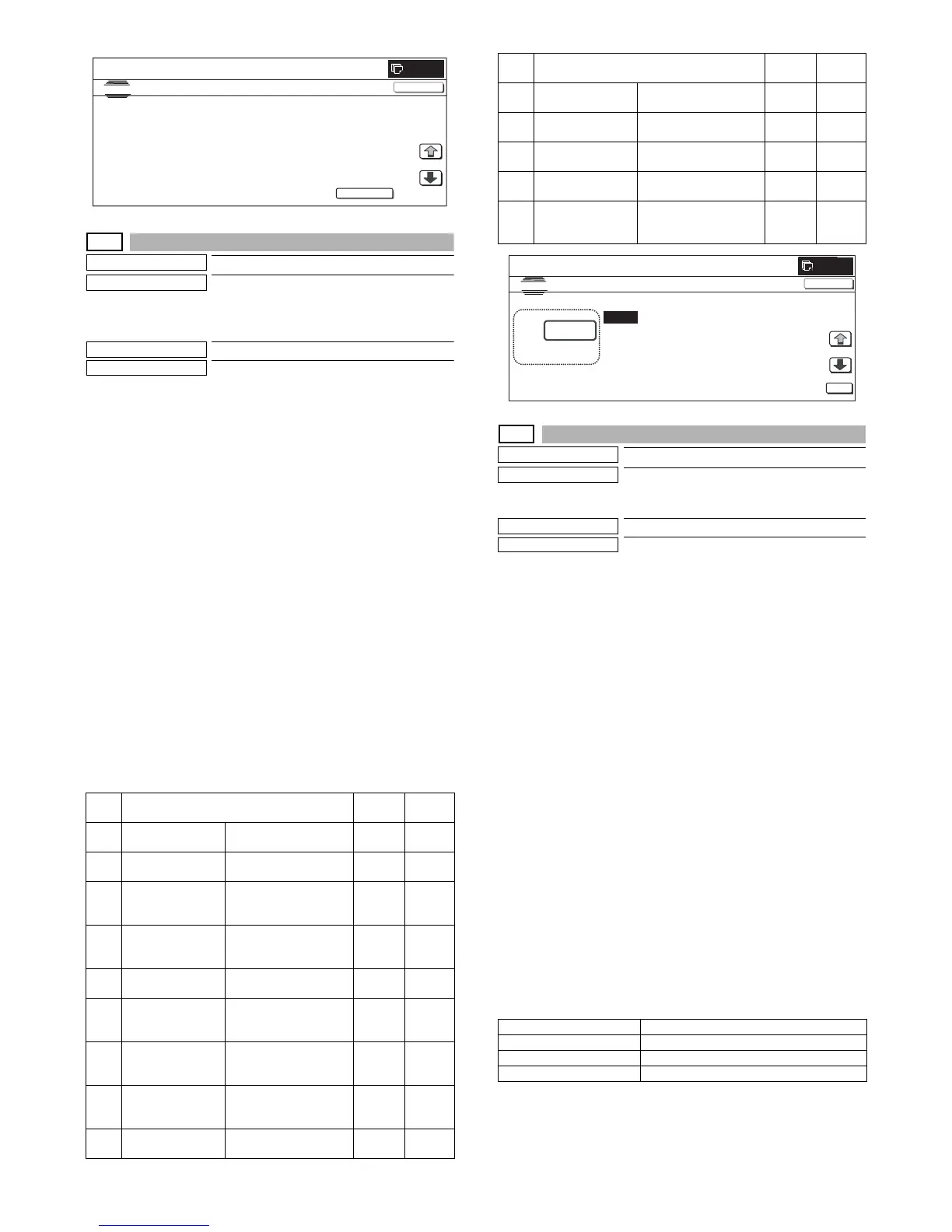

44-6

Purpose

Operation test/Check

Function (Purpose)

Used to forcibly execute the correction in

the image process section (high-density

process correction) (process correction).

Section

Process

Item

Operation

Operation/Procedure

1) When the machine enters SIM 44-06, the screen shown on the

right is displayed.

2) When [EXECUTE] button is pressed, it is highlighted and all

the drum motors are driven to rotate. The high-density process

control is started.

3) While the high-density process control is executed, "NOW

EXECUTING..." is displayed.

4) After completion of the high-density process control, the drum

motors are stopped and [EXECUTE] button returns to the nor-

mal display.

When the operation is completed normally, "COMPLETE" is

displayed and the execution result is saved to EEPROM and

RAM.

In case of an error, "ERROR" is displayed and the details of

the error are displayed below.

* When the high-density process control is interrupted by an

external factor (pressing [EXECUTE] button), the forcible

interruption screen is displayed and the drum motors are

stopped. [EXECUTE] button returns to the normal display.

* The result of the high-density process control is displayed

with the following simulations:

SIM.44-09 (Process control result display (High density cor-

rection))

SIM.44-12 (Process control result display (Half tone correc-

tion))

<Result display and content description>

Item Display content

Set

range

Default

value

A PCS_CL TARGET Color sensor target set

value

1 to 255 108

B PCS_K TARGET Black sensor target set

value

1 to 255 155

C LED_CL OUTPUT Color sensor light

emitting quantity set

value

1 to 255 21

D LED_K OUTPUT Black sensor light

emitting quantity set

value

1 to 255 21

E PCS ADJSTMENT

LIMIT

Sensor adjustment

target limit value

1 to 255 2

F BELT GROUND

DIF

Belt 1 lap, effective

difference between

upper and lower values

1 to 255 255

GBIAS_CL

STANDARD DIF

Bias (for color)

reference calculating

difference

0 to 255 0

HBIAS_BK

STANDARD DIF

Bias (for black)

reference calculating

difference

0 to 255 0

I BIAS PATCH

INTERVAL

Patch bias output

interval

1 to 255 60

0

SIMULATION NO.4402

TEST

PROCON GAI N ADJUSTMENT

EXECUTE

PCS_CL LED ADJ

21

:

PCS_㧷 GRND

0

:

PCS_㧷 LED ADJ

21

:

PCS_K BELTM AX

0

:

PCS_CL DARK

0

:

PCS_K BELTM IN

0

:

PCS_K DARK

0

:

PCS_K BELTDIF

0

:

1/3

Loading...

Loading...