21

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

a) When touching the pads, a certain group of pads do not produce a signal.

b) When touching the pads, no pads produce a signal.

2-2 In connection with indicators

a) At a certain digit, all or some segments do not light up.

b) At a certain digit, brightness is low.

c) Only one indicator does not light.

d) The corresponding segments of all digits do not light up; or they continue to light up.

e) Wrong figure appears.

f ) A certain group of indicators do not light up.

g) The figure of all digits flicker.

2-3 Other possible problems caused by defective control unit.

a) Buzzer does not sound or continues to sound.

b) Clock does not operate properly.

c) Cooking is not possible.

When testing is completed,

1) Disconnect the power supply cord, and then remove outer case.

2) Open the door and block it open.

3) Discharge high voltage capacitor.

4) Reconnect all leads removed from components during testing.

5) Re-install the outer case (cabinet).

6) Reconnect the power supply cord after the outer case is installed.

7) Run the oven and check all functions.

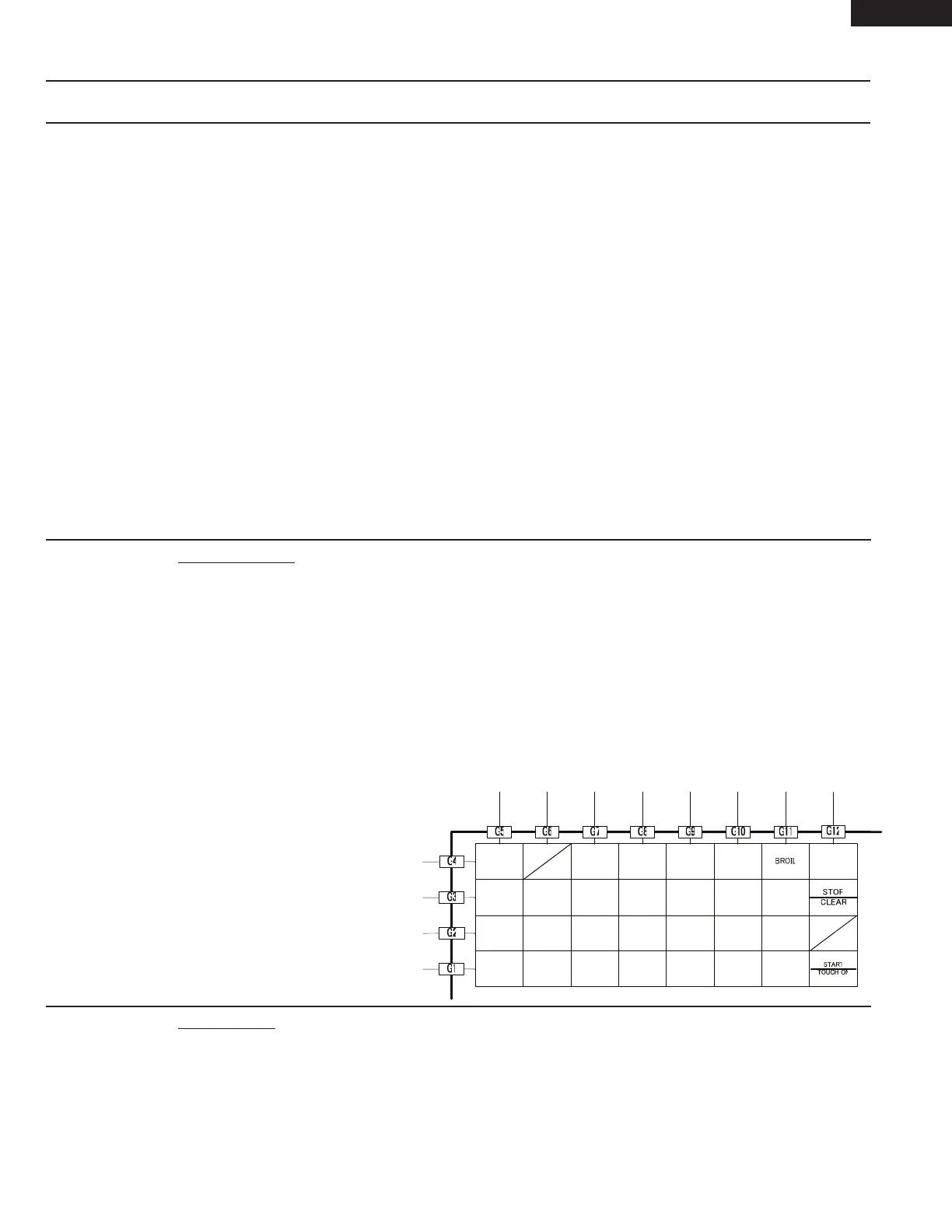

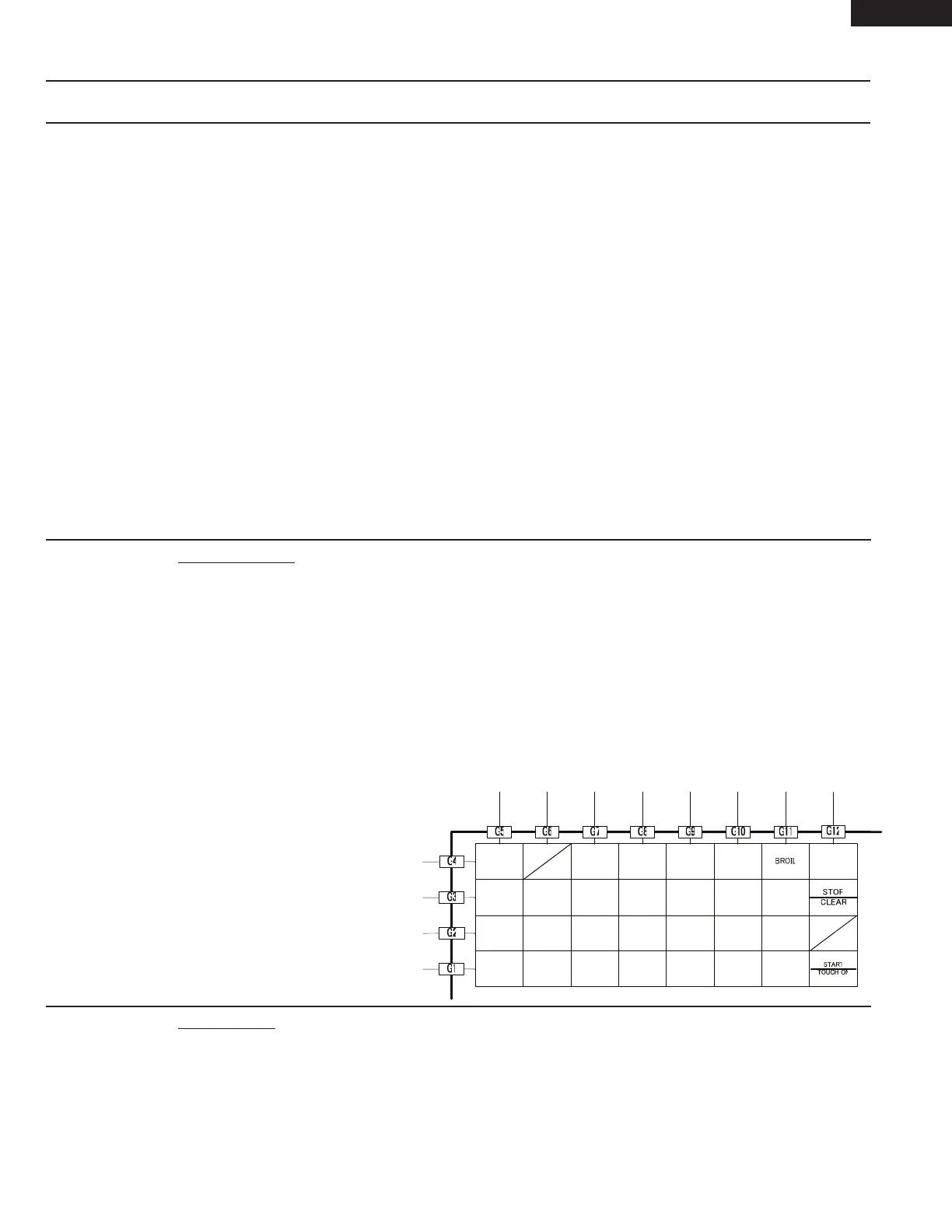

R KEY UNIT TEST

1. Disconnect the power supply cord, and then remove outer case.

2. Open the door and block it open.

3. Discharge high voltage capacitor.

4. If the display fails to clear when the STOP/CLEAR pad is depressed, first verify the flat ribbon cable is

making good contact, verify that the door sensing switch (stop switch) operates properly; that is the

contacts are closed when the door is closed and open when the door is open. If the door sensing switch

(stop switch) is good, disconnect the flat ribbon cable that connects the key unit to the control unit and make

sure the door sensing switch is closed (either close the door or short the door sensing switch connecter).

Use the Key unit matrix indicated on the control panel schematic and place a jumper wire between the pins

that correspond to the STOP/CLEAR pad making momentary contact. If the control unit responds by

clearing with a beep the key unit is faulty and must be replaced. If the control unit does not respond, it is

faulty and must be replaced. If a specific pad does not respond, the above method may be used (after

clearing the control unit) to

determine if the

control unit or key

pad is at fault.

5. Reconnect all leads removed from

components during testing.

6. Re-install the outer case (cabinet).

7. Reconnect the power supply cord

after the outer case is installed.

8. Run the oven and check all

functions.

S RELAY TEST

1. Disconnect the power supply cord, and then remove outer case.

2. Open the door and block it open.

3. Discharge high voltage capacitor.

4. Disconnect the leads to the primary of the power transformer.

5. Ensure that these leads remain isolated from other components and oven chassis by using insulation tape.

6. After that procedure, re-connect the power supply cord.

7. Remove the outer case and check voltage between Pin Nos. 7 and 9 of the 9 pin connector (A) on the

control unit with an A.C. voltmeter. The meter should indicate 120 volts, if not check oven circuit.

SENSOR

MENU

1

100F

2

150F

7

375F

8

400F

HIGH

MIX

AUTO

DEFROST

HELP/

SETTINGS

AUTO

BRKE

AUTO

BROIL

AUTO

ROAST

POWER

LEVEL

3

275F

6

350F

9

425F

CLOCK

4

300F

TIMER

0

450F

5

325F

+60 SEC

REHEAT

CONVECT

POPCORN

LOW

MIX

PREHEAT

SLOW

COOK

SMC1585BSA

SMC1585BBA

SMC1585BWA

Loading...

Loading...