-27- -28-

狀況1 :跳針、斷線—

排除:

A 是否使用錯誤型號之機針。

B 使用機針是否已彎曲,毛邊或未裝至定位

或未裝正。

C 車縫線是否存放過久或線本身粗細不均,

接頭太多或有漏穿線情形。

D 注意針線及底線(下勾針線)之控線沙拉組

是否太緊或太鬆。

E 底線(下勾針線)之控線凸輪時位關係,檢查

是否已走位。(此項須由技術人員檢查調整)

F 檢查前後護針片之相關位置是否正確。

(此項須由技術人員檢查調整)

G 下勾針尖是否已毛邊磨損,或下勾針與針

之時位關係已被調整走位。(此項須由技

術人員檢查調整)

狀況2 :車縫不順產生布料波浪或斜紋

狀況—

排除:

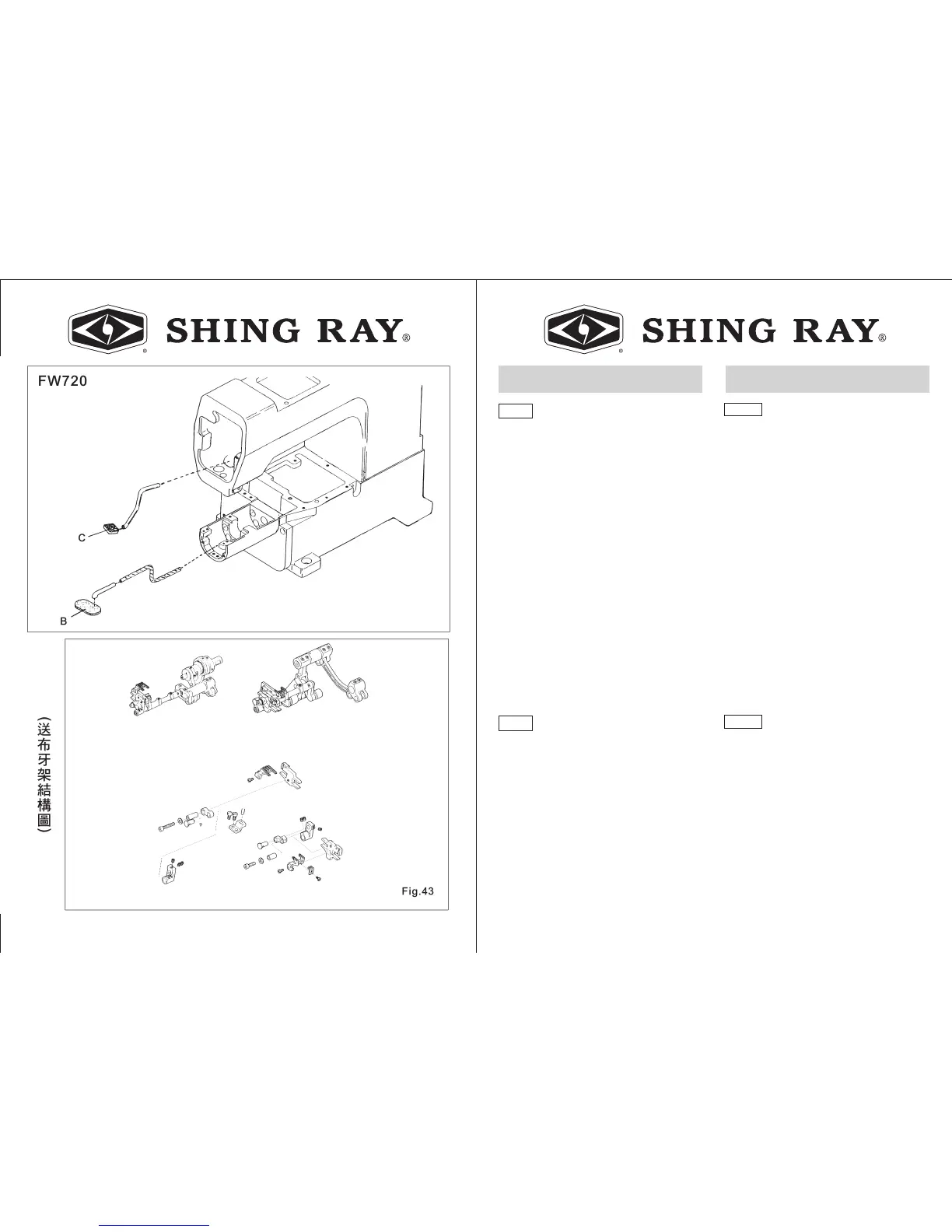

A 針對布料性質調整前牙差動比率:

波浪情形—前牙差動調大;

斜紋情形—前牙差動調小。

B 注意押腳壓力須適中,且不能與針板面有

間隙。

B 故障(用戶)自主檢查:

Status 1 : Skipped Stitch, Broken Thread-

Solution :

(a) Do you use a wrong model needle?

(b) Does the needle bent? Does the tip of needle

cracked? Or, the needle doesn't be installed in

correctly position.

(c) Does the thread keep in stock too long? Does

the thread's thickness uneven? Does the thread

too many connecters? Or, there is lose

threading some threading eyelet.

(d) Please check the tension of needle & looper

thread have been adjusted too loosen or too tight

by Thread Tension Adjuster.

(e) The looper thread take-up is out of timing.

(Please ask the machinist to check and adjust it.)

(f) Please check the relative position of Front &

Rear Needle Guard are correctly. ( Please ask

the machinist to check and adjust it.)

(g) Please check the tip of looper have cracked or

wore. The timing of looper and needle is out of

order. ( Please ask the machinist to checkand

adjust it.)

Status 2 :

The Unstable Sewing engender Puckering

and the folding parts didn't be seamed

in even -

Solution :

(a) To refer the nature of fabric for adjusting the

differential feed-dog. Differential Rate :

Puckering

-

To adjust the differential feed-dog

ratio in large.

The folding parts didn't be seamed in even-To

adjust the differential feed-dog ratioin small.

(b)

The pressure of presser foot must be moderately.

Please take care that the needle plate between

presser foot didn't have any gap.

B. ERROR MESSAGES

(

THE USER INSPECTS

THE MACHINE BY THEMSELVES)

Loading...

Loading...