-25-

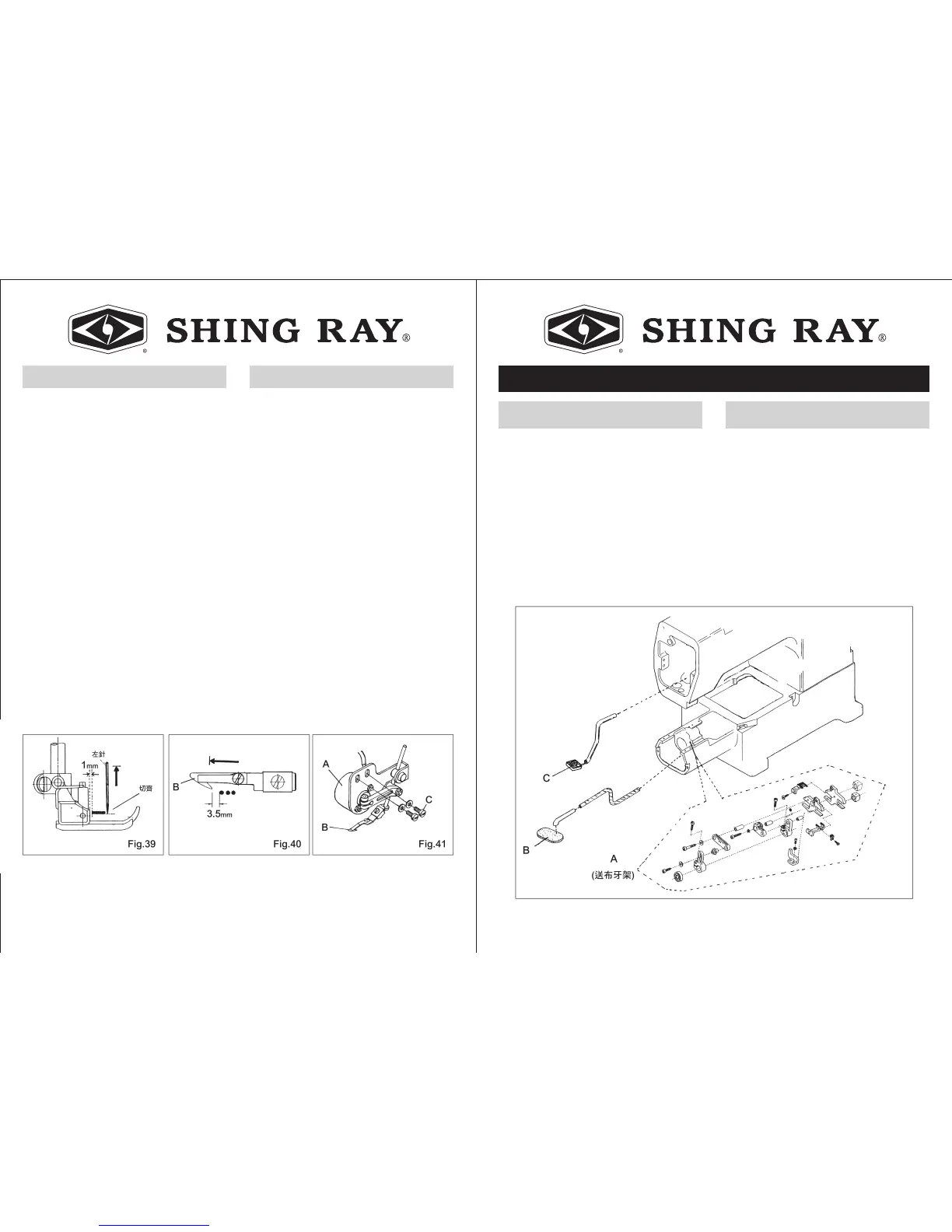

1. 撥線器(A)之高度—

當撥線片(B)往下擺動至呈水平狀態

時,撥線片底部與左針之針尖正好

切齊,此為撥線器之高度。(圖39)

2. 撥線片(B)之前後位置—

當撥線片(B)通過押腳時,撥線片與

押腳前沿之間隙為1mm。(圖39)

3. 撥線片(B)之左右位置—

當撥線片(B)移到左定點時,撥線片

之勾線尖端與左針之距離約為3.5mm。

(圖40)

注:

調整時,可放鬆兩個螺絲(C),調整撥線器

(A)之相關位置。(圖41)

E 撥線器相關位置調整:

1. The height of Top Wiper (A)

-

When the Wiper (B) swings to the bottom

in level, the bottom of Wiper align with

the tip of left needle which is the height

of Top Wiper. (Fig.39)

2.

The front & rear position of Wiper (B)

-

When the Wiper (B) passed the Presser

Foot, the clearance between the Wiper and

Presser Foot is 1mm. (Fig.39)

3.

The right & left position of Wiper (B)

-

When the Wiper (B) swings to the left dead

point, the clearance between the hook tip

of Wiper and left needle is 3.5mm. (Fig.40)

Remarks :

To loose the two screws (C) for adjusting

the relative position of Top Wiper (A)﹒

(Fig﹒41)

E.

THE RELATIVE POSITION OF TOP WIPER.

-26-

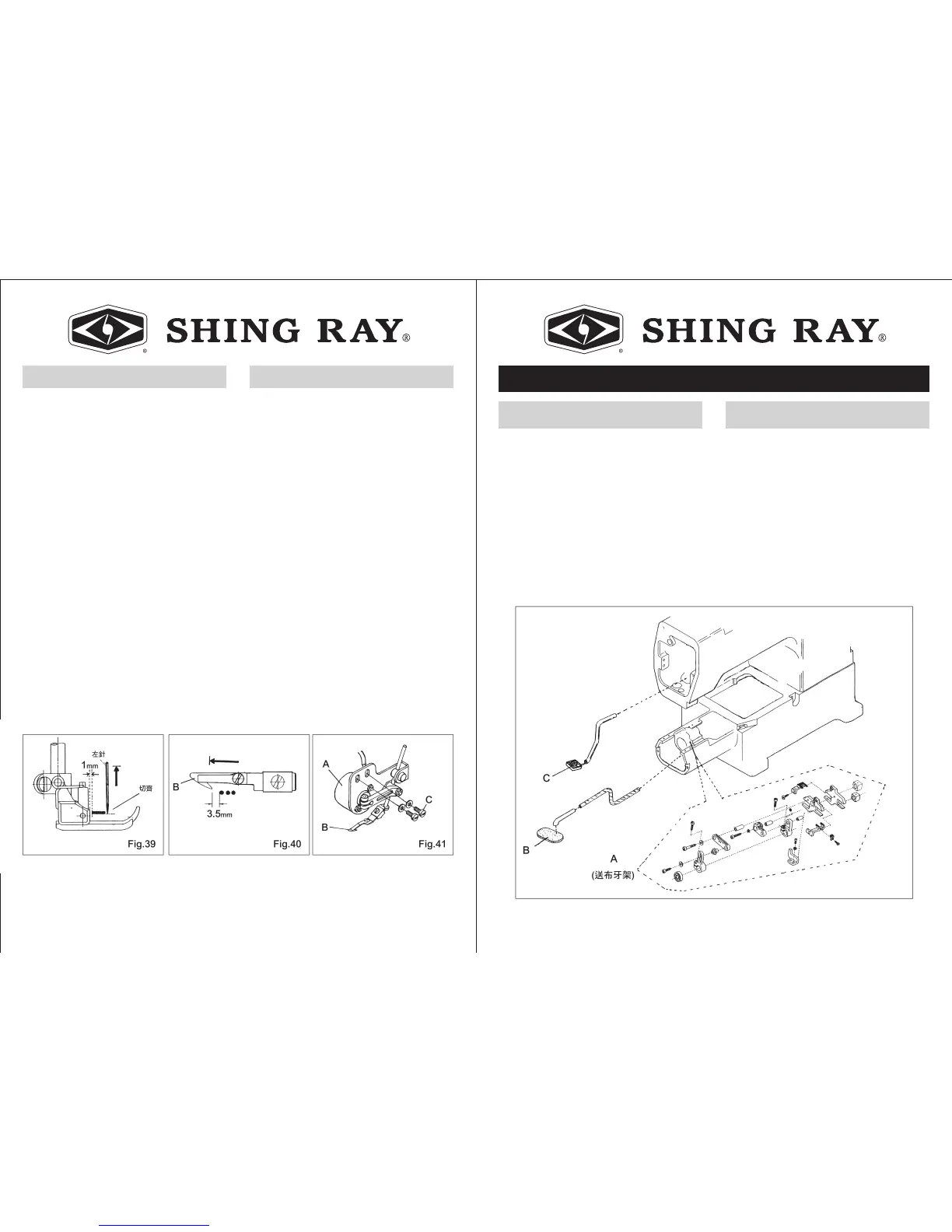

1. 機器外表須經常保持乾淨避免棉屑阻

塞過線孔及夾線片,造成線跡不順。

2. 針板下方之送布牙架結構(A)縫隙之

清潔最為重要,須經常清除乾淨。

如有積油而造成滲油情況,就是棉屑

累積太多或吸油管阻塞造成的。故須

定期清除送布牙架(A)裡面及更換回

油管之吸油海棉(B)、(C)。(圖42)

A 清潔保養:

1.

Please always clean the machine appearance

to avoid the cotton waste obstructs the threading

hole and thread clamp which to cause the stitch

unstable.

2.

It's very import to always clean the crack (A)

of feed dog system which under the needle

plate. If the cotton waste accumulate too many

in cylinder or block the suck oil tube for which

will cause the oil leaking. Please always clean

the Feed-Dog System and change the felt of

suck oil tube (B), (C) in regularly. (Fig.42)

A. THE CLEAR AND MAINTENANCE.

簡易故障排除

REGULAR MAINTENANCE :

FW787

Fig.42

Loading...

Loading...