SHOPSMITH MARK V 845180

Page 6

now.

Also, remember that your MARK V could possibly

go out of alignment if it is moved to an area with

varying floor levelness. Remember to recheck

alignment and make needed adjustments after

moving your MARK V, if needed.

ADJUST THE HEADREST LOCK

(ALL MARK V MODELS)

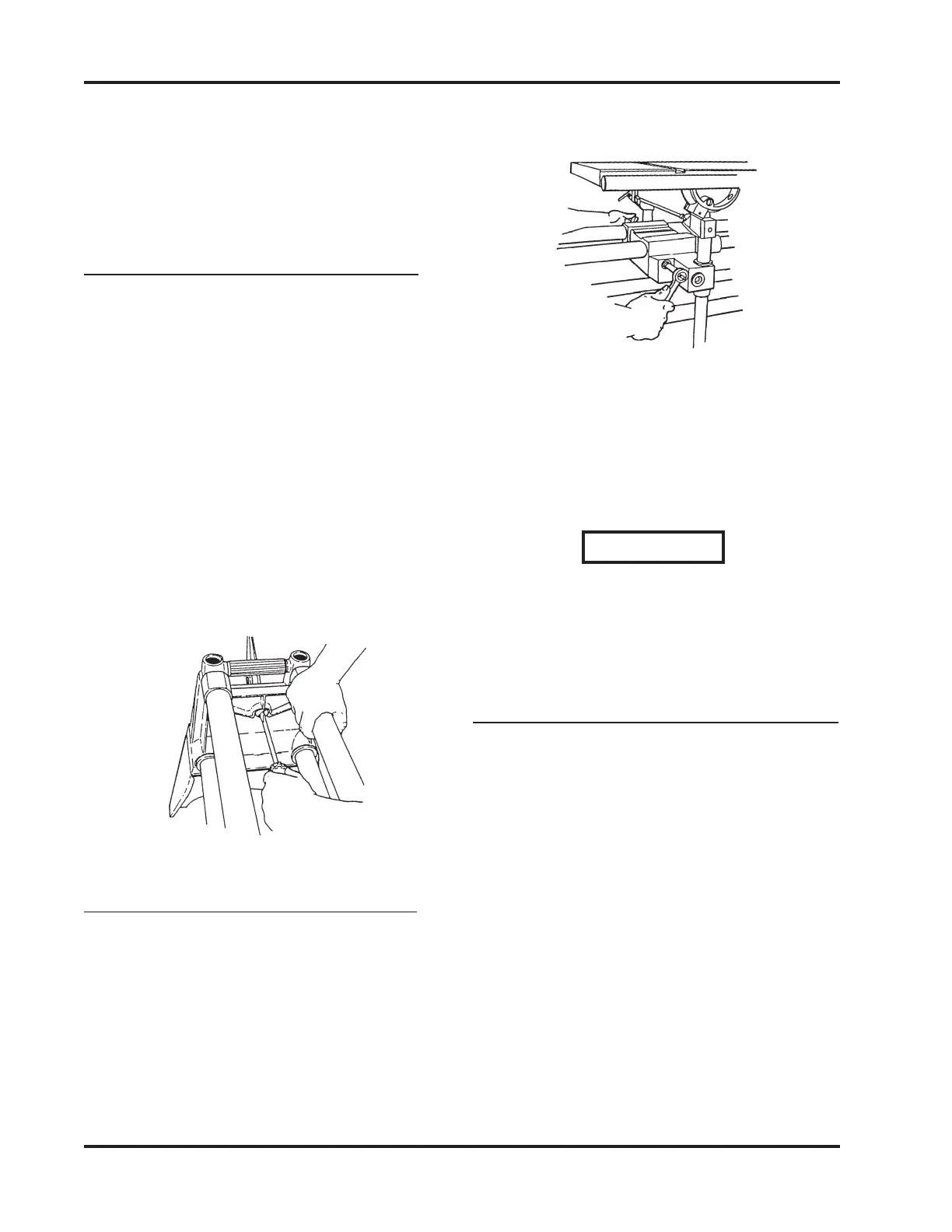

1. To check the Headrest Lock, grasp the

Way Tubes near the Tie Bar and pull up,

as demonstrated by the Right Hand in

Figure 1.

2. If there is "give" in the Lock, unlock the

Handle and use Medium Straight Blade

Screwdriver to turn the Lock Shaft clock-

wise, as done by the Left Hand in Figure

1. If the Lock is difficult to operate, the

Lock Shaft is too tight. To loosen, unlock

the Handle and turn the Lock Shaft coun-

terclockwise.

Figure 1

ADJUST THE CARRIAGE LOCK

(MARK V MODELS 510 & 520)

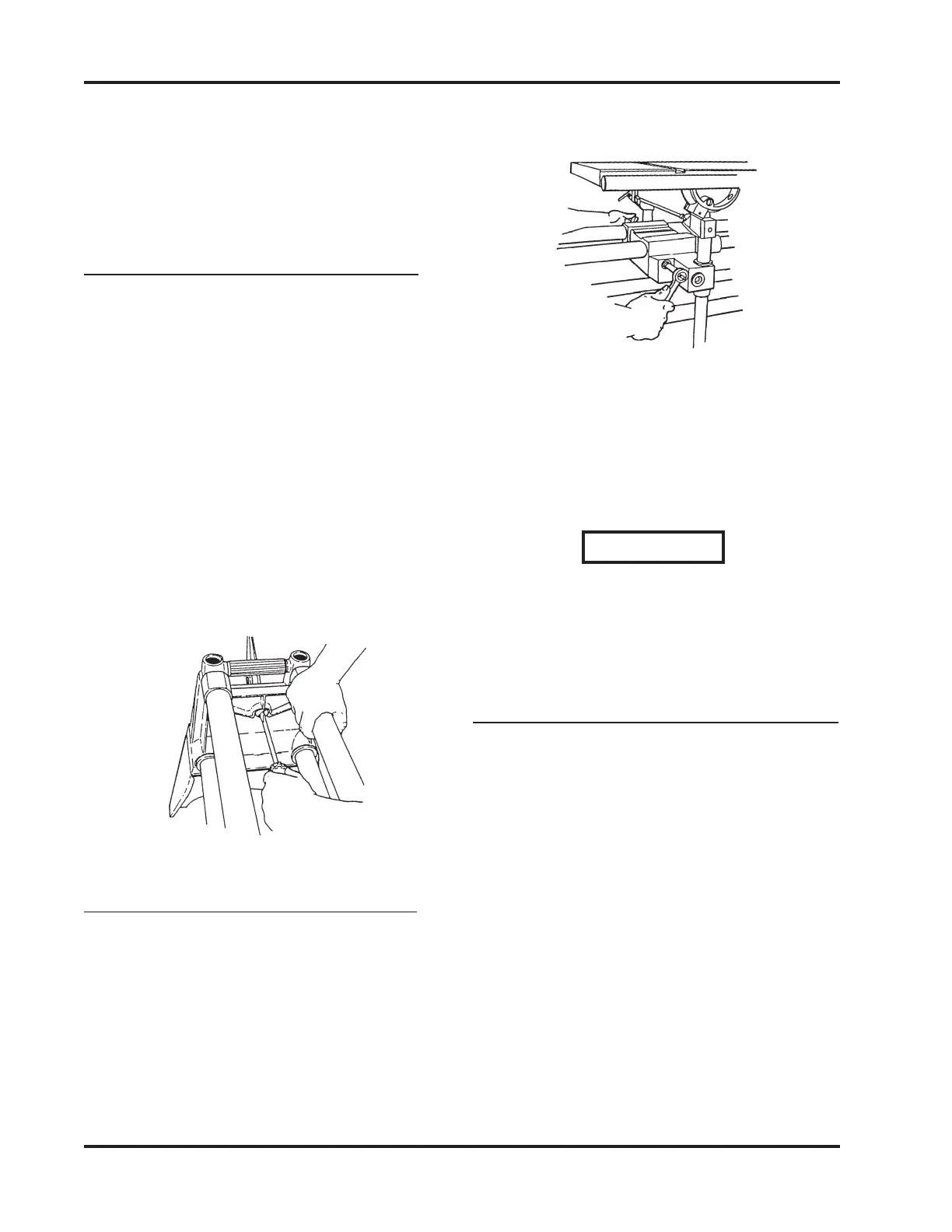

1. If the Carriage Lock Handle does not

lock past the horizontal position to four-

o’clock or the Carriage moves when the

lock handle is in this position, the Lock

needs adjusting. To adjust the Lock, use

a 1/2" Socket with an Extension and

Ratchet Handle to tighten or loosen the

Nut located at the back of the Carriage

Assembly, as shown in Figure 2.

Figure 2

2. When the Carriage Lock Handle locks

past the horizontal position to four-

o’clock and the Carriage no longer moves

when the Handle is in this position,

tighten the Nut a final 1/4 turn.

WARNING

The Carriage Lock Handle MUST lock

past the horizontal position to Four-

O’clock, otherwise the Carriage Lock

will vibrate loose.

SET WORKTABLE'S 90° LEFT STOP

(MARK V MODEL 500)

1. Unlock the Carriage and Headstock.

Move the Headstock to the middle of the

Way Tubes. Then move the Carriage

between the Headstock and Base Mount

(right side).

2. Tighten the Headstock and Carriage

Locks. Place the MARK V in the vertical

position by loosening the Headrest

Handle, firmly grasping the Way Tubes

near the Headrest end, and lifting the

Tubes into the 90° position, as demon-

strated in Figure 3.

Loading...

Loading...