3

Before any intervention on the device, the power supply must be cut-off. The

electrical connection must be performed by a qualied professional in compliance

with the applicable standards in the country. Only use the supplied 2 conductors +

ground cable that must be connected to earth (class 1 device). This socket must be

accessible after installation.

Use only the three-conductor

cable supplied

• Blue/Neutral

• Brown/Live

• Green & Yellow/Earth

An all-pole mains disconnect switch with a contact separation ensuring a complete

cut-off, as per Overvoltage Category III, must be provided in xed installations in

accordance with the installation instructions.

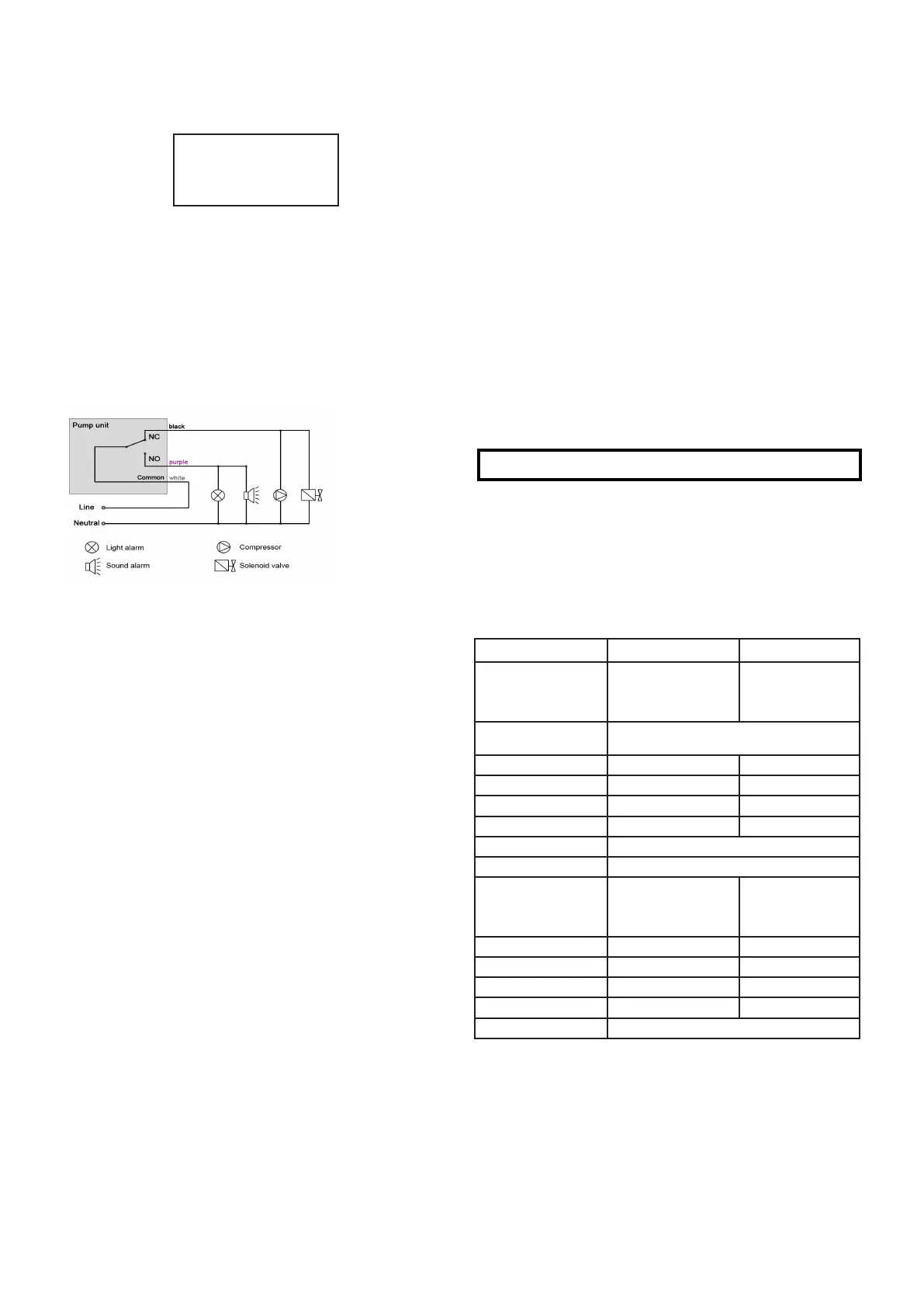

2.d ELECTRICAL CONNECTION OF THE ALARM

There is a change-over contact with a maximum breaking capacity of 4A at 250V

(resistive) and a minimum of 10mA at 5 VDC. Use the alarm (visual or audible

alarm) installed by you to notify of any risk of overow (NO contact) and to cut off

the condensate production (NC contact). The supplied three conductor cable must

be used:

2.e HYDRAULIC CONNECTION

You can use one or more of the four holes diameter 27.5 mm by breaking the cap

with a screwdriver to collect the water to be evacuated by possibly using our gear

reducer Ref. GCO78H2008 (not supplied) for diameters of 40, 32 and 25 mm.

Discharge takes place at the check valve outlet which has a smoothed end-piece

diameter 12 mm for an inner tube diameter of 10 mm. You can, by using the reducer

kit provided (reducer diameter 12/8 mm + intermediate tube), connect a PVC tube

of diameter 6x9 mm. NB: with this set up ow rates will be reduced. Make sure

that the tube used allows a perfectly airtight and mechanically sound connection to

remain compatible with the ow rate and pressure of this pump

Activation: Pour some water into the pump until it runs and then stops. Resume

the test by rapidly pouring in water to reach the alarm level and check the proper

operation of this safety device: visual or audible signal or shutdown of refrigeration.

MAINTENANCE

This operation must be performed by a qualied professional and always with the

power off. The inside of the tank should be cleaned regularly by removing the pump

from the tank and using a 5% bleach solution. Run the liquid through the pump for

one minute.

Next, rinse thoroughly with clean water by running the pump for one minute.

Then, check that all hydraulic and electrical connections are compliant and follow

the operating instructions described above. If the cable is damaged, it must be

replaced by the manufacturer, its after-sales service or similarly qualied persons

in order to avoid any possible hazards.

SAFETY

• Siccom strongly recommends that the high level alarm cable be

connected to an audible or visual alarm or is used to stop the production

of condensates.

• The pump motor is equipped with a thermal cut-off set to 120°C with

automatic restart.

• Connection of the earth wire (class 1 device)

WARRANTY

Your pump is guaranteed to be in perfect working order at delivery. Pumps produced

by SICCOM SAS are guaranteed for 1 years (12 months) from the SICCOM SAS

billing date against all operating faults. In the case of detection of a fault, customers

not located in France must return the pump postage paid to the nearest SICCOM

distributor. All products returned will be subject to a complete analysis of origin

and operation in relation to its traceability code and the technical performances

ascertained. If it is determined that the fault is unrelated to incorrect use of the

pump and that the installation instructions have been complied with, the product

will be repaired or replaced.

RESTRICTIONS:

Any implicit guarantee will be limited to the duration of the express guarantee

specied above. In all cases, the responsibility related to the SICCOM SAS

warranty is limited to the replacement or repair of the product supplied plus the

cost of its transport to the original delivery location.

NEITHER THE VENDOR NOR THE MANUFACTURER IS RESPONSIBLE

FOR INJURIES OR DAMAGES DIRECTLY RELATED TO THE PRODUCT

OR SUBSEQUENT TO ITS USE (INCLUDING BUT NOT LIMITED TO LOSS

OF PROFIT, LOSS OF TURNOVER, DAMAGE TO GOODS OR PERSONS

DIRECTLY RELATED TO THE PRODUCT OR RESULTING FROM ITS USE)

OR ANY PREJUDICE ARISING FROM THE USE OF OR INABILITY TO USE

THE PRODUCT. THE USER AGREES THAT THIS SITUATION IS WITHOUT

RECOURSE OR COMPENSATION.

THE WARRANTY WILL BE INVALIDATED IN THE FOLLOWING CASES:

- Pump motor cover opened

- Product connected to an incorrect supply voltage

- Pump used with any other liquid than condensate water

- Incorrect use of the pump by the customer

- Alarm not connected

Before using the product, the user must determine whether it is compatible with his

or her intended use of the product. They will be responsible for all risks and legal

implications resulting from its use or installation.

SICCOM SAS reserves the right to modify the product completely or partially

without rst informing its customers about it

DE

BESCHREIBUNG

ECO TANK ist eine Zentrifugalpumpe aus einem Stück mit großem Durchuss,

die Kondenswasser aus Klimaanlagen, Kühlanlagen oder aus Heizkesseln mit

Gasverdichtung ableitet.Aufgrund ihrer 135 mm Höhe mm ist sie besonders für

Kühlvitrinen, Verdampfer und Kühlschränke geeignet.

Technische Eigenschaften

ECOTANK +

1.2 L 2.5 L

Art der Flüssigkeit:

Kondenswasser mit

einem pH > 2,5 und

einer Temperatur

< 40°C < 40°C

Stromversorgung/

Leistung

230 V 50 Hz / 65 W

Betriebstemperatu 3°C à 45°C 3°C à 45°C

Lagertemperatur: 0 à 70°C 0 à 70°C

Klasse: Geräteklasse 1 1

Maximaler Durchuss 300 l/h 400 l/h

Maximale Fördermenge 4,6 meter

Einschaltdauer S3 (30%) 170 s ON / 340 s OFF

Integrierte

Alarmfunktion: Kontakte

normal offen + normal

geschlossen

Maximal 3A resistiv

unter 250 V 50 Hz

Maximal 3A resistiv

unter 250 V 50 Hz

Volumen der Wanne 1,2 l 2.5 l

Hitzeschutz des Motors Oui Oui

Schutzindex IP20 IP20

Höhe der Pumpe 12,9 cm 15.9 cm

Aufstellungshöhe < 2500 m

Stellen Sie bitte sicher, dass diese Eigenschaften mit allen Anforderungen

Ihrer Anwendung kompatibel sind.

Loading...

Loading...