42

The motor will run until the normally closed Stop button

is pressed, unless the overload relay (OL) contacts open.

When the Stop button is pressed, the path for current flow is

interrupted, opening the associated M and Ma contacts, and

the motor stops.

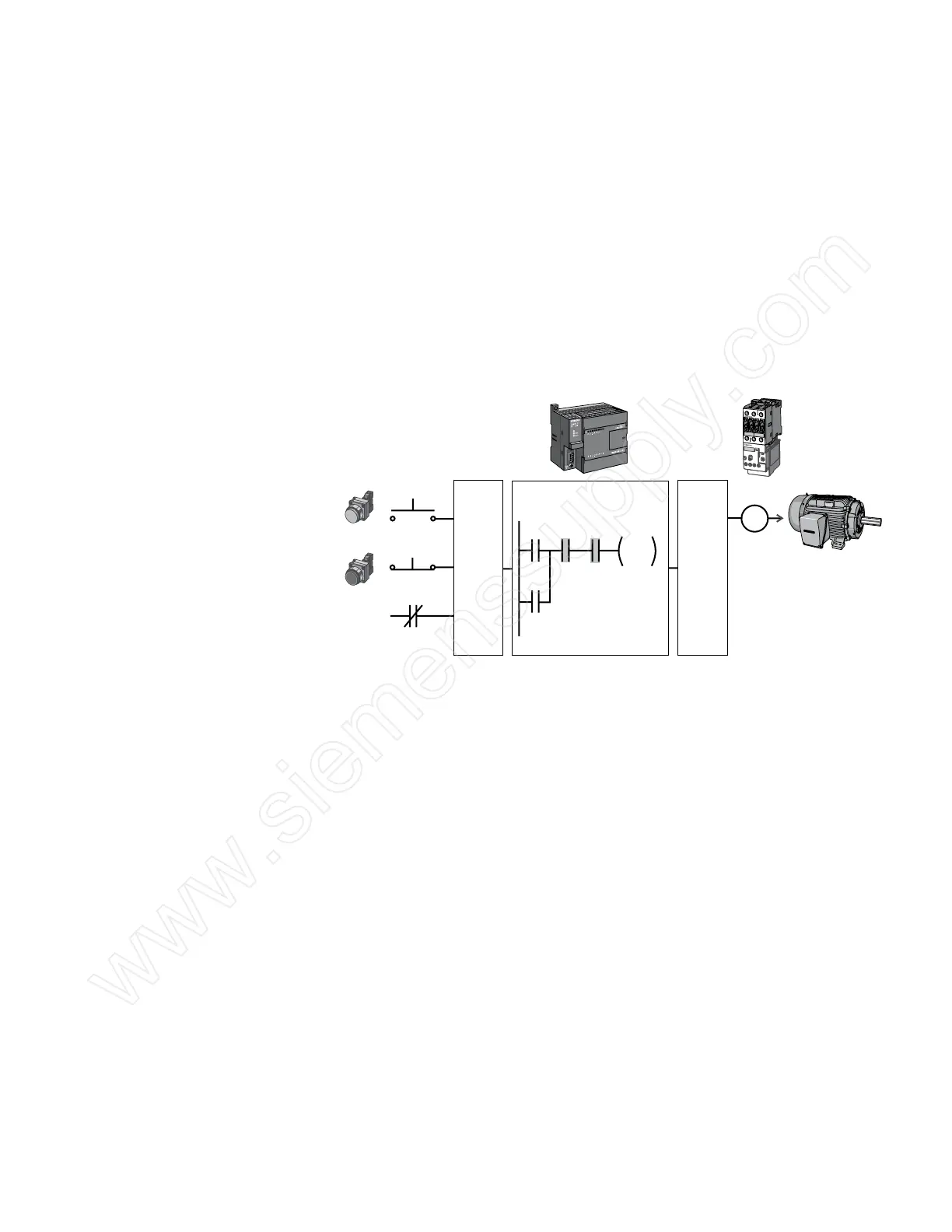

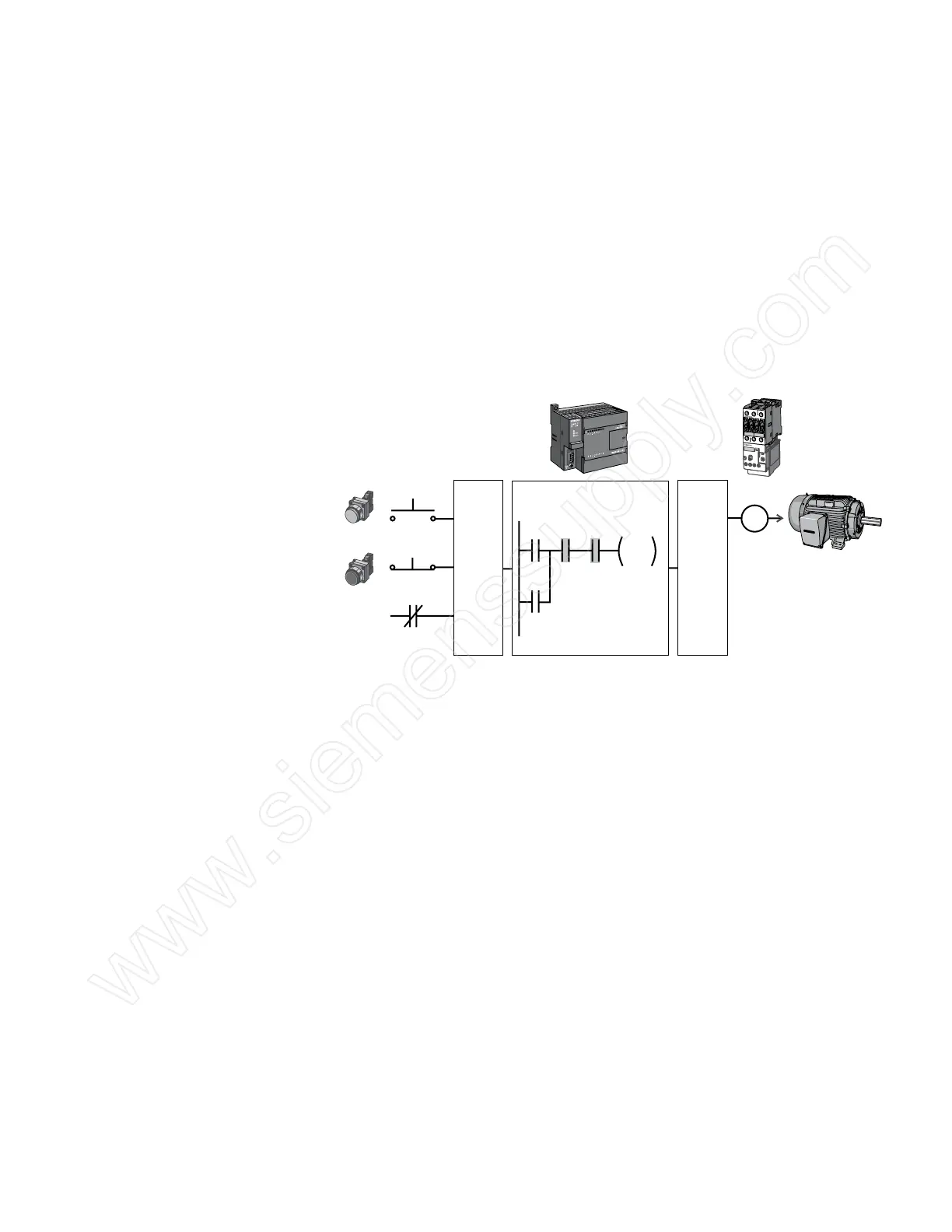

PLC Motor Control This motor control application can also be accomplished

with a PLC. In the following example, a normally open Start

pushbutton is wired to the first input (I0.0), a normally closed

Stop pushbutton is wired to the second input (I0.1), and

normally closed overload relay contacts (part of the motor

starter) are connected to the third input (I0.2). These inputs are

used to control normally open contacts in a line of ladder logic

programmed into the PLC.

SF/DIAG

Start (NO)

Stop (NC)

OL

I0.0

I0.1

I0.2

Input

Points

Output

Point

Q0.0

Network 1

CPU Program

I0.0 I0.1 I0.2

Q0.0

Q0.0

Motor

Starter

Motor

Initially, I0.1 status bit is a logic 1 because the normally closed

(NC) Stop Pushbutton is closed. I0.2 status bit is a logic 1

because the normally closed (NC) overload relay (OL) contacts

are closed. I0.0 status bit is a logic 0, however, because the

normally open Start pushbutton has not been pressed.

Normally open output Q0.0 contact is also programmed on

Network 1 as a sealing contact. With this simple network,

energizing output coil Q0.0 is required to turn on the motor.

Loading...

Loading...