44

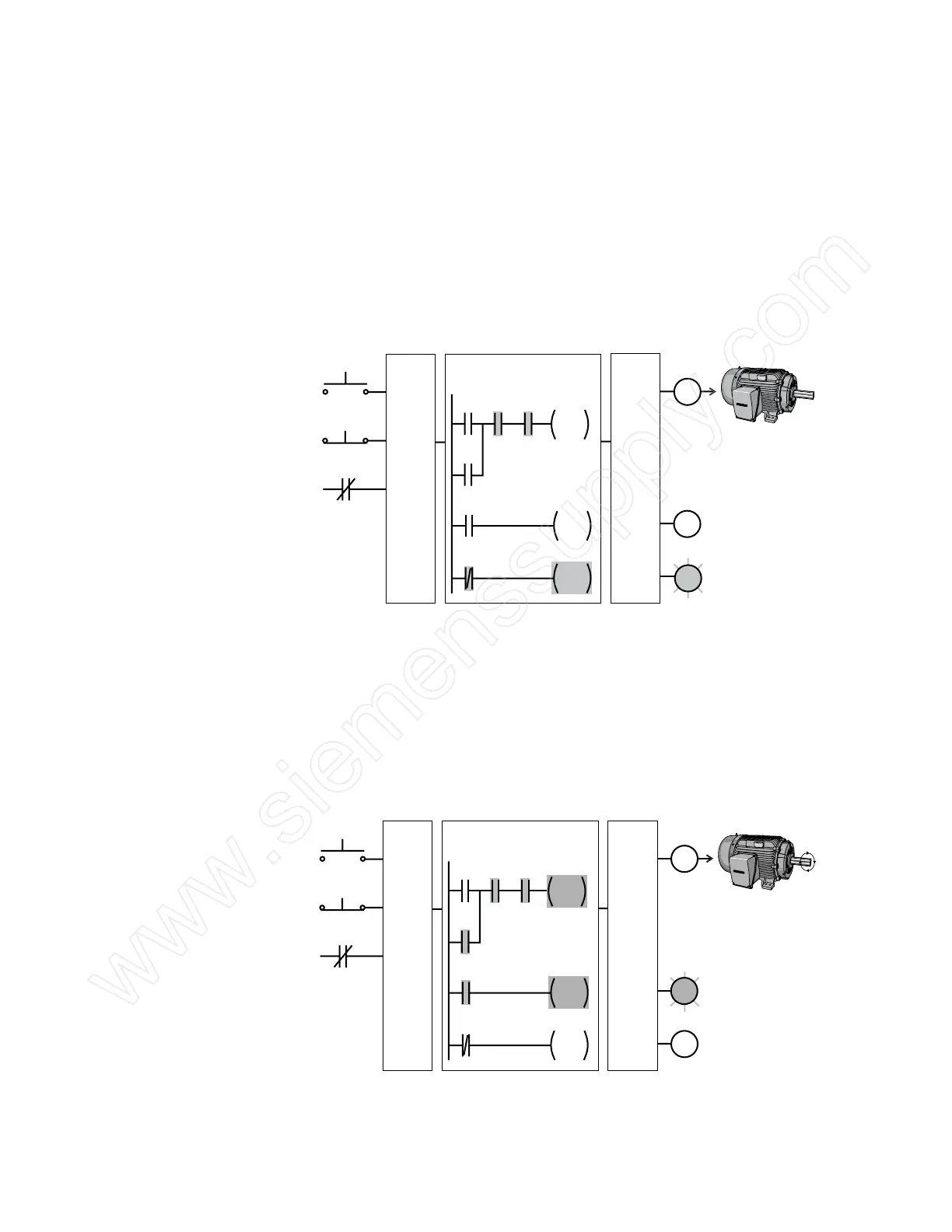

Adding Run and Stop The application can be easily expanded to include indicator

Indicator Lights lights for run and stop conditions. In this example, a RUN

indicator light is connected to output Q0.1 and a STOP indicator

light is connected to output Q0.2.

The ladder logic for this application includes normally open

Q0.0 contact connected on Network 2 to output coil Q0.1

and normally closed Q0.0 contact connected on Network 3

to output coil Q0.2. When Q0.0 is off, the normally open Q0.0

contact on Network 2 is open and the RUN indicator off. At the

same time, the normally closed Q0.0 contact is closed and the

STOP indicator is on.

Start (NO)

Stop (NC)

OL

I0.0

I0.1

I0.2

Input

Points

Output

Points

Q0.0

Network 1

CPU Program

I0.0 I0.1 I0.2

Q0.0

Q0.0

Motor

Starter

Motor

Q0.1

Q0.2

Q0.1

Q0.2

Q0.0

Q0.0

Network 2

Network 3

STOP Indicator

RUN Indicator

Motor is

Stopped

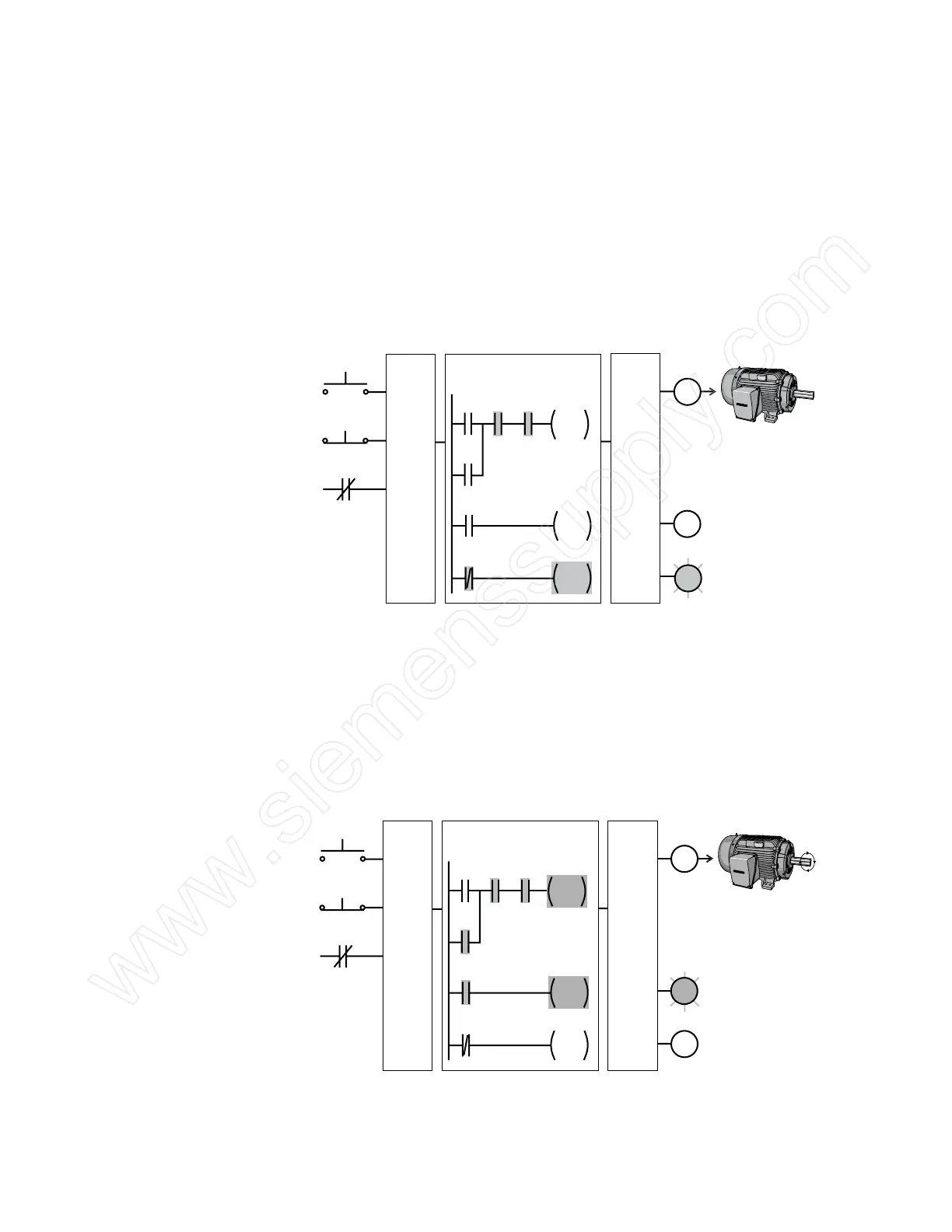

When the Start button is pressed, the PLC starts the motor.

Output Q0.0 is now on. Normally open Q0.0 contact on

Network 2 is now closed and the RUN indicator is on. At the

same time, the normally closed Q0.0 contact on Network 3 is

open and the STOP indicator light connected to output Q0.2 is

off.

Motor is

Running

Start (NO)

Stop (NC)

OL

I0.0

I0.1

I0.2

Input

Points

Output

Points

Q0.0

Network 1

CPU Program

I0.0 I0.1 I0.2

Q0.0

Q0.0

Motor

Starter

Motor

Q0.1

Q0.2

Q0.1

Q0.2

Q0.0

Q0.0

Network 2

Network 3

STOP Indicator

RUN Indicator

Loading...

Loading...