18BMaintenance

Standard motors

56100000002001, 02/2013

61

Bearing lifetime

Prolonged storage periods reduce the useful lifetime of the bearing grease. In the

case of permanently lubricated bearings, this leads to a shorter bearing lifetime.

Bearing or grease replacement is recommended after a storage time of 12 months,

for longer than four years, replace the bearings or grease.

Replacing bearings

Recommended interval after which bearings are to be replaced under normal

operating conditions:

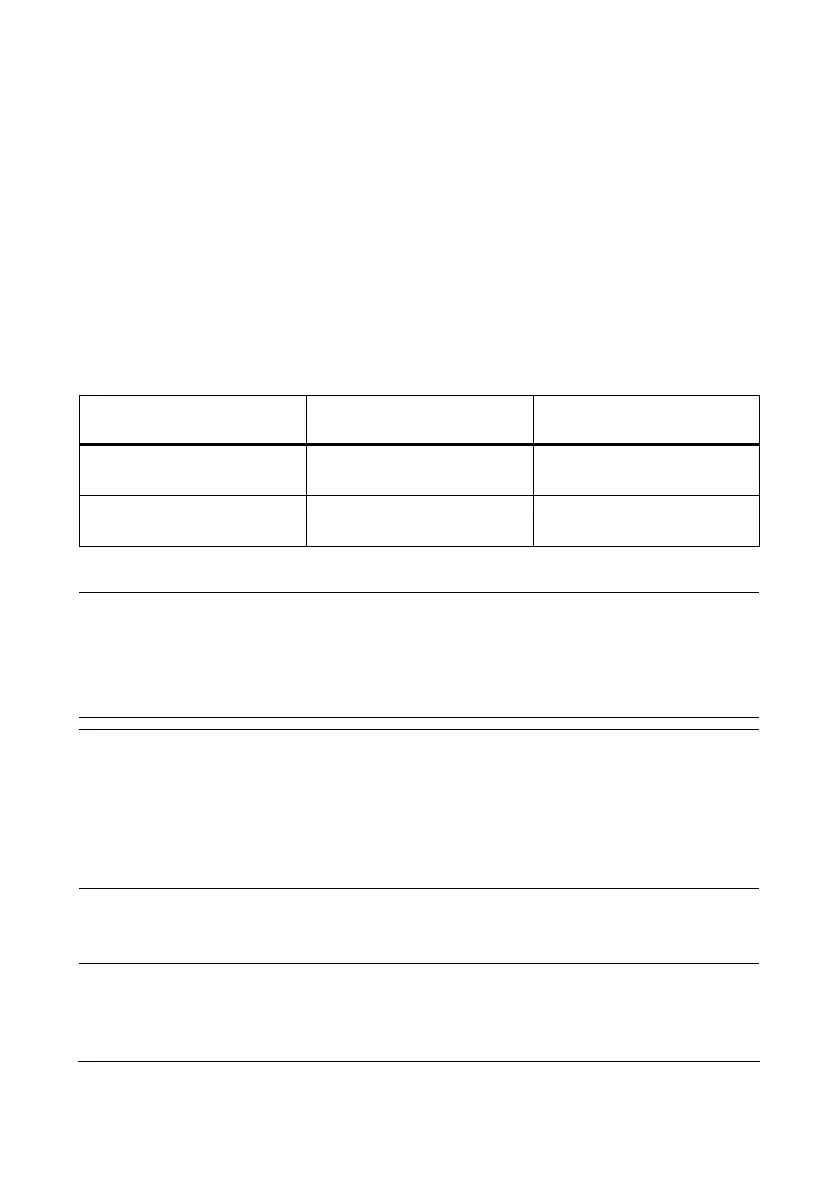

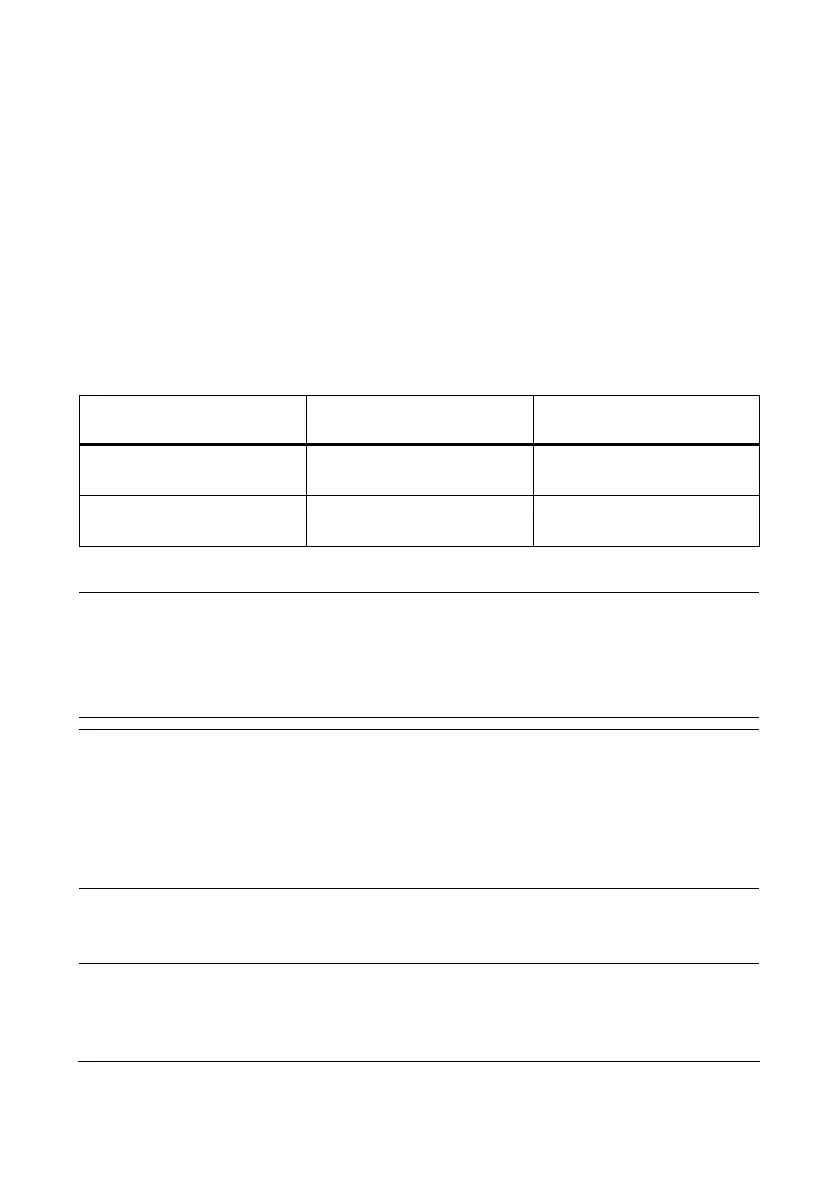

Table 9-1 Bearing replacement intervals

Ambient temperature Principle of operation Bearing replacement

intervals

40° C Horizontal coupling

operation

40 000 h

40° C With axial and radial

forces

20 000 h

Note

Special operating conditions

Examples of factors that can reduce operating hours are vertical machine installation,

high vibrational and impact loads, frequent reversing, higher ambient temperature,

higher speeds, etc.

Note

● Do not reuse bearings that have been removed.

● Remove any existing contaminated old grease from the bearing shield!

● Replace old grease with new grease!

● Replace the shaft seals when the bearings are replaced.

● Lightly grease the contact surfaces of the sealing lips!

9.2.3 Dismantling

Note

Before commencing disassembly, you should mark how each of the fastening

elements has been assigned, as well as how internal connections are arranged, for

re-assembly purposes.

Loading...

Loading...