s

© Siemens AG 2013-2015 A5E43029185

To ensure better heat dissipation, do not insert any insulators between

the motor flange and the mounting flange.

Mount the motor through a mounting steel

flange, as shown in the left figure.

• Low inertia motor:

2 x M4 (1FL602❑)

❑

)

Tightening torque 4.7 Nm

❑

4 x M8 (1FL605❑)

120x100x40

• High inertia motor:

❑

)

Tightening torque: 8 Nm

❑

)

Tightening torque: 20 Nm

4 x M12 (1FL609❑)

420x420x20

Use a flexible coupling with high torsional

rigidity specifically designed for servo

motors, which allow to transfer the motor

torque to the mechanics and to

compensate radial, axial and angular

misalignments.

Do not strike the shaft when installing a

coupling and ensure that the radial and

axial forces are smaller than the allowable

maximum values specified in the Operating

When a motor is used with a flange coupling, ensure that the radial

deviation is smaller than 0.03 mm. Otherwise, the bearing will be

The required alignment accuracy differs with the motor speed and the

coupling type. Please determine the accuracy according to actual

• Turn the motor shaft and the machine

shaft to align the coupling.

• An alignment accuracy test is preferred.

If unachievable, judge the accuracy by

observing whether the coupling can slide

smoothly on both shafts.

If the coupling gives out abnormal sounds, refer to the step “Aligning a

coupling” to realign the coupling until the sounds disappear.

The belt tension must be smaller than the allowable radial forces of the

• Measure the belt tension at multiple

points using a tension meter while

turning the motor shaft by 45°.

• Try your best to reduce the axial

misalignment of the belt-pulleys to keep

the axial forces to the motor shaft to a

minimum

.

Do not use a motor with an oil seal submerged in oil.

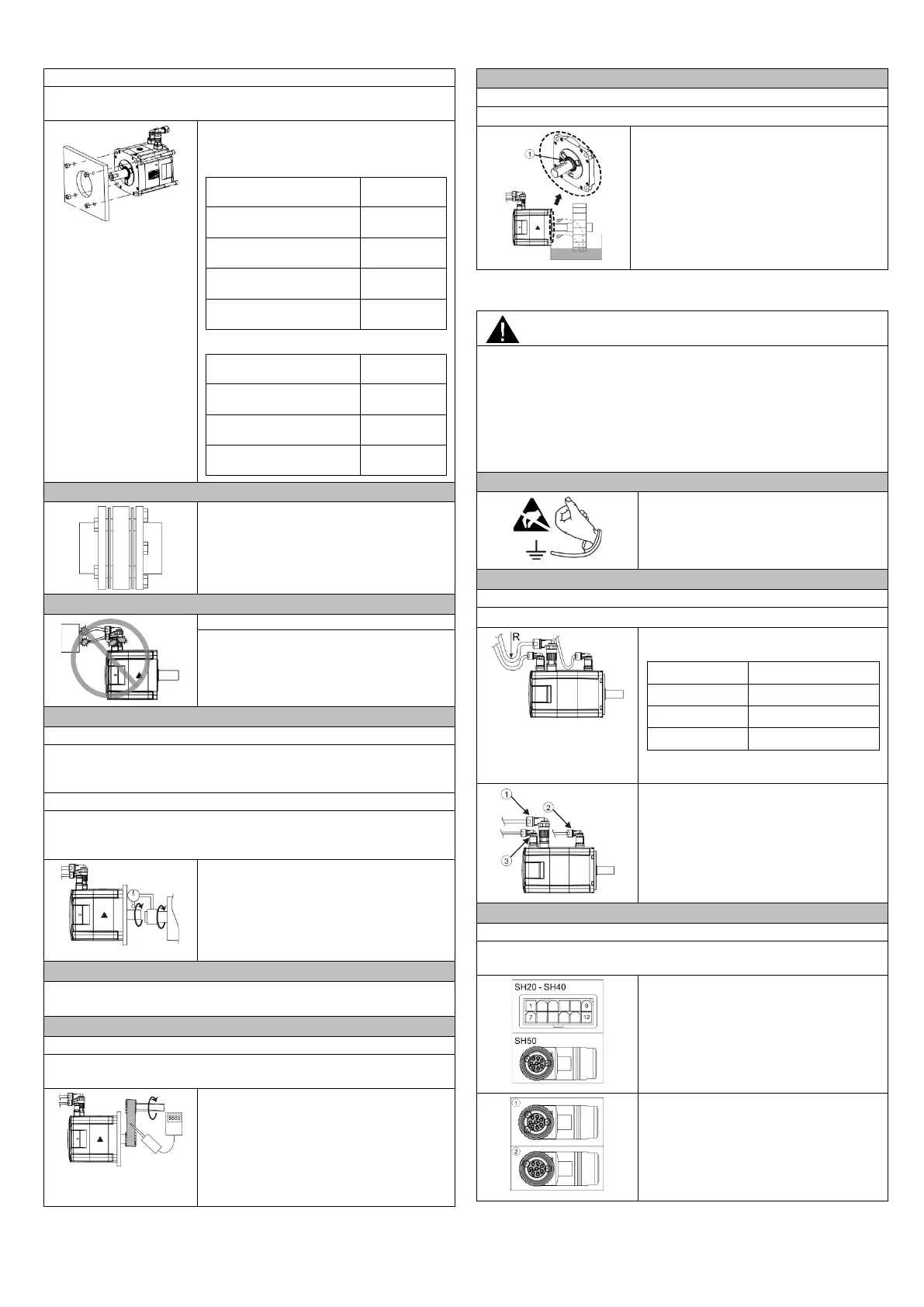

The oil seal (①) should be used with

sufficient lubricant oil splashed on it.

4 Electrical installation

Personal injuries by hazardous voltage and unregulated move

If you connect the cables with the power supply switched on, it may

cause personal injuries by a hazardous voltage and unregulated move

from the motor.

• Switch off the power supply.

• Make sure that there are no voltage conditions.

• Prevent the energy sources from switching on again.

Before connecting the cables, you must

take necessary ESD protection measures,

e.g. wearing an ESD wrist strap, ESD

gloves, and ESD clothes.

Do not put much stress upon cables or connectors while wiring.

The minimum cable bending radiuses

are listed as follows:

Type Radius

Power cable 6 x outer diameter

Encoder cable 6 x outer diameter

Brake cable 6 x outer diameter

The minimum dynamic bending radius

Connect the cables in the following order:

1. Encoder cable (③)

2. Brake cable (②)

3. Power cable (①)

Connecting the encoder cable

Do not touch the encoder pins at the motor with naked hands to avoid

For the low inertia motor with shaft-height

50 mm, the incremental encoder cable

connector has two notches.

For the high inertia motor, the absolute

encoder cable connector (①) has three

notches. The incremental encoder cable

connector (②) has two notches.

Loading...

Loading...