s

© Siemens AG 2013-2015 A5E43029185

4. Electrical, magnetic and electromagnetic fields generated in

operation that can pose a risk to people with a pacemaker,

implants or metal replacement joints, etc., if they are too close.

5. Release of environmental pollutants or emissions as a result of

improper operation of the system and/or failure to dispose of

components safely and correctly.

The components must be protected against conductive contamination

(e.g. by installing them in a control cabinet with degree of protection

IP54 according to IEC 60529 or NEMA 12).

Assuming that conductive contamination at the installation site can

definitely be excluded, a lower degree of cabinet protection may be

permitted.

For more information about residual risks of the components in a drive

system, see the relevant sections in the technical user documentation.

1.5 Warning labels

Warning labels on servo motors

Do not strike the shaft end or the keyway.

The surface temperature of the motor may exceed 80°C. Do

not touch the hot surfaces.

Warning labels in this document

Indicates that death, severe personal injuries or material

damages may result if proper precautions are not taken.

Indicates the actions that must not be performed.

2 Installation environment

• Operation:

− Low inertia motor: 0°C to 40°C

− High inertia motor: 0°C to 40°C

Note: When the surrounding

temperature is between 30 °C and

40 °C, the 1FL605❑ motors and

1FL609❑ motors with brake will have a

power derating of 10%.

• Storage:

− Low inertia motor: -20°C to 65°C

− High inertia motor: -15°C to 65°C

• Operation: ≤ 90% RH (non-condensing

at 30°C)

• Storage: ≤ 90% RH (non-condensing at

30°C)

≤ 1000 m

≤ 49 m/s

2

• Continuous axial shock:

≤ 25 m/s

2

• Continuous radial shock: ≤ 50 m/s

2

• Short-term (6 ms) shock:

≤ 250 m/s

2

To avoid magnetic interference to the absolute encoder, do not use

electromagnetic devices near the absolute encoder, such as

electromagnetic memory sticks, memory cards, and key cards.

Keep the servo motor with an absolute

encoder at least 15 mm away from the

devices that produce a magnetic field

stronger than 10 mT.

• A motor with fitted connectors has a

protection class of IP65 (dust-tight and

water jetting proof). The shaft opening

(②) is protected with an oil seal.

• To guarantee adequate protection, use

specified connectors

(①) when wiring.

3 Mechanical installation

Lifting a motor (for high inertia motor only)

Death or injuries by unresolved burdens

At the transport the motor can cause death or injuries by unchecked

movements.

• Use lifting equipments and load suspension devices which are only

interpreted for the burden of the motor and intact.

• Do not stay under and in the jib range of unresolved burdens.

• Safeguard the motor against rolling away at the side when removing.

• Do not lift a motor by pulling the cables.

Do not overtighten the eyebolts of 1FL609❑ motors.

• For 1FL609❑ motors, the eyebolts must

be manually screwed in completely.

• Lift 1FL609❑ motors at the eyebolts.

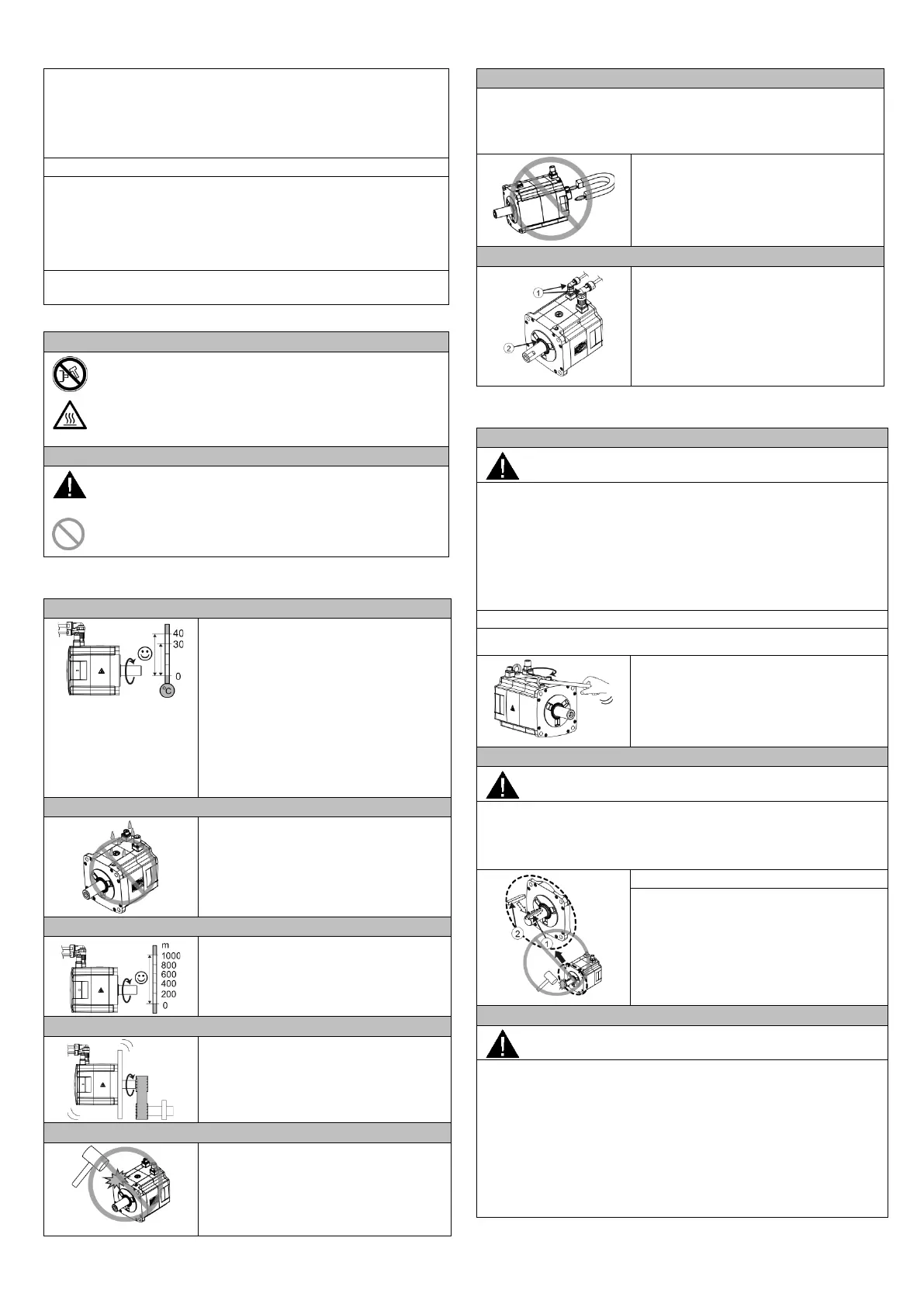

Installing a key (optional)

Injuries by an ejected key

When a motor using a key is running, the fitted key on the shaft may be

ejected, which can cause personal injuries. The fitted key on the shaft

must be firmly secured to prevent them from being flung out.

For the motor using a key (②), the key is

preinstalled on the shaft extension. When

reinstalling it, do not strike the key slot (①).

Personal injuries and material damages by the drop of a vertical

axis

When a servo motor with a brake is used as a vertical axis, the axis will

drop if the positive and negative poles of the 24 V DC power supply for

the servo drive are connected inversely. Unexpected drop may cause

personal injuries and material damages.

Before commissioning, mechanical end stops should be fixed at the

end of the absolute traversing range of the machine axis in prevention

of an unexpected drop. In addition, make sure that the 24 V DC power

supply is correctly connected.

Loading...

Loading...