840D/828D SINUMERIK Operate Page 3

B502

B502

Notes

Section 2

Right hand rule

Z-Axis: This is parallel to the working spindle or coincides with it. The

positive direction is away from the work piece. In case there is more

than one spindle, one of them will be declared as the main spindle.

X-Axis: This is parallel to the setting-up plane or coincides with it. If the

Z-axis is vertical, the positive X-axis is directed towards the right. If the

Z-axis is horizontal, the positive X-axis is directed towards the left.

Y-Axis: This is at right angles to both the X- and Z-axis, such that a

spatial cartesian coordinate system results.

The direction "FROM" the work piece "TO" the tool is "PLUS".

A mobile tool must "ALWAYS" be programmed!

Definition of axis according to DIN-standard

Explanation:

According to DIN standard the various axes of motion within work space of

CNC machines are addressed by alphabets.

The machine coordinate system that is derived from the DIN-standard be-

comes extremely important for the geometrical description of work pieces

which allows us to clearly determine the points in a plane or in space.

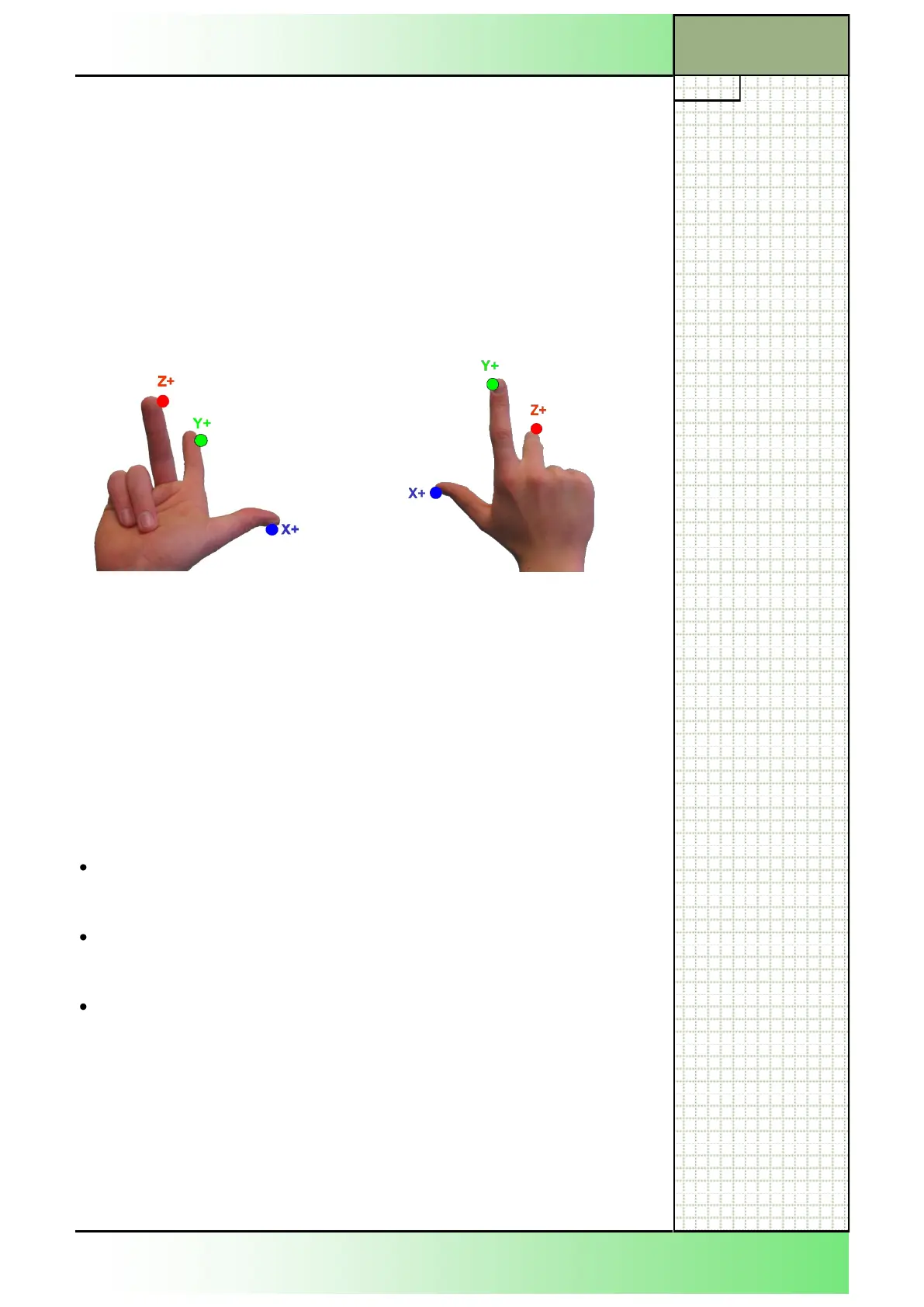

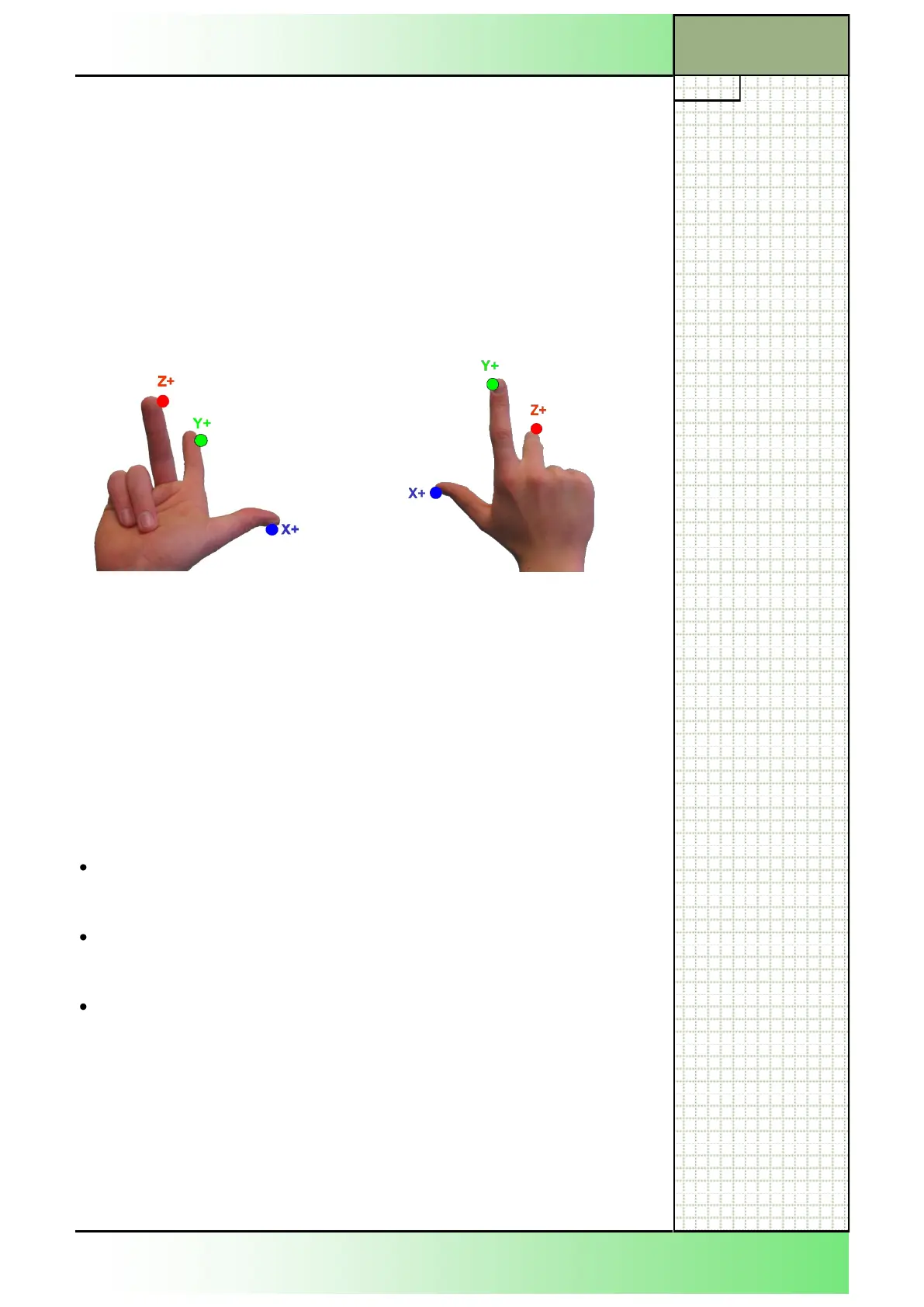

The cartesian (rectangular) spatial coordinate system can be best de-

scribed with the "Right hand rule". Here the fingers of the right hand rep-

resent the axes: “X” (thumb), “Y” (first finger) and “Z” (middle finger). The

finger tips point in the positive direction.

The position of the machine coordinate system is specified by the machine

manufacturer keeping the following in mind:

Vertical turning machine

Horizontal milling machine

Loading...

Loading...