840D/828D SINUMERIK Operate Page 5

B502

B502

Notes

Explanation:

For the determination of all points within the work space, the control unit

requires a zero point of the coordinate system. This has been determined

by the machine manufacturer. All other points have either fixed distances

from the machine zero point or else the distance must be defined.

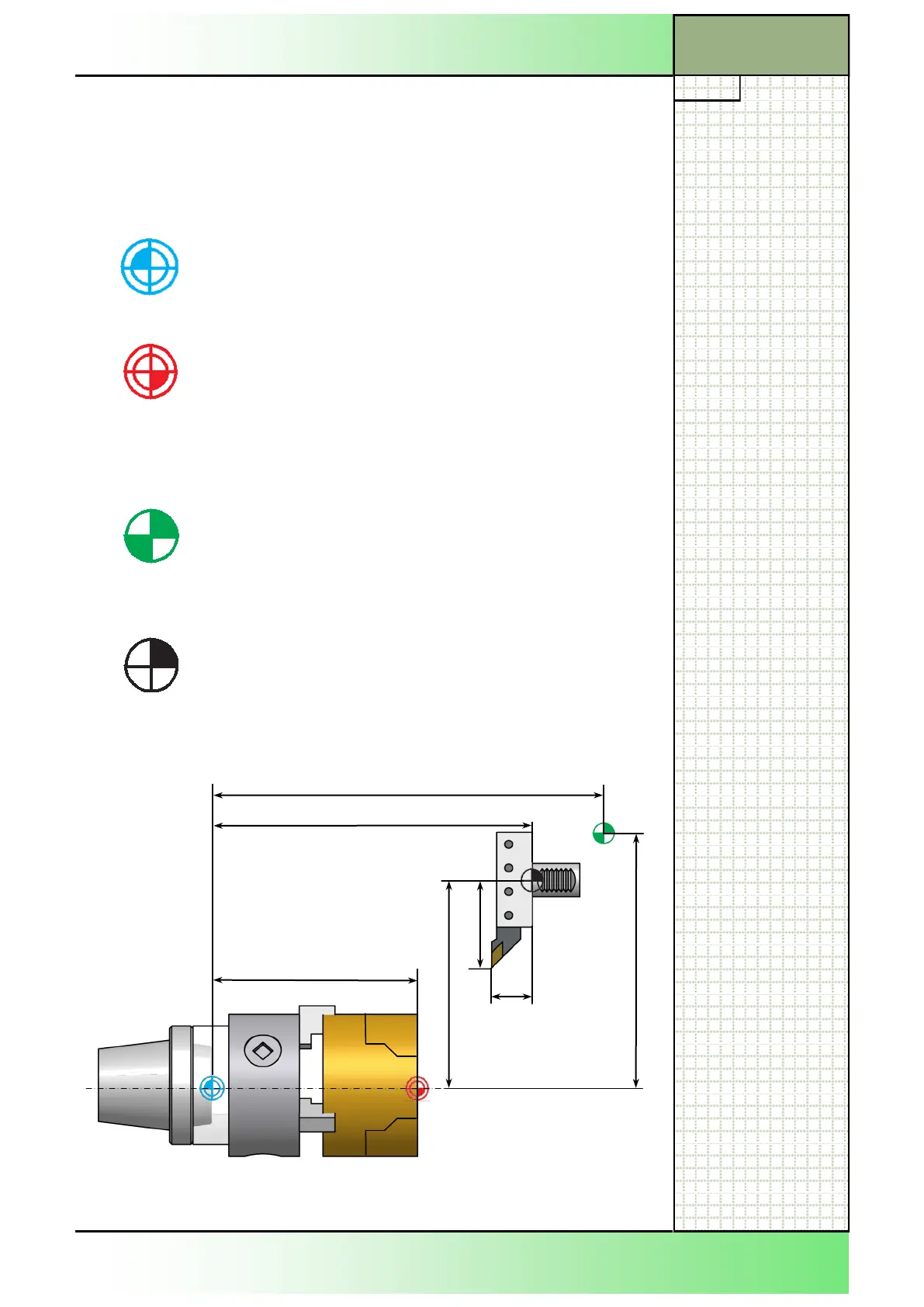

The machine zero point (M) is determined by the

machine manufacturer and cannot be altered. On

milling machines it usually lies on the work table,

while on turning machines it is on the spindle flange.

The work piece zero point (W) is the origin of the

work piece coordinate system. This can be specified

by the programmer and should always be chosen in

a way that the least calculation work is required to

determine points on the contour given the dimen-

sioning of the drawing. For turning work it lies mostly

on the turning axis and the right hand planar face.

The reference point (R) is approached for initializ-

ing the path measuring system, which means that at

this point all axes are set to zero. This is necessary

since generally speaking the machine zero point

cannot be approached.

The tool carrier reference point (F) is of prime im-

portance for the adjustment of preset tools. The

lengths L (XPF) and offset O (ZPF) shown in the im-

age below are used as tool calculation values for

instance for the tool radius correction and must be

entered into the tool memory of the control unit.

ZMW

ZMR

ZMF

XMR

ZPF

XMF

XPF

Points and distances within the work space

Section 4

Loading...

Loading...