840D/828D SINUMERIK Operate Page 3

B503

B503

Notes

Section 2

Absolute and incremental dimensioning, mixed programming

When writing CNC-Programs a fundamental differentiation must be made

between absolute and incremental coordinates.

Which of the two options the programmer chooses depends on the usage

of the program and the dimensioning on the drawing.

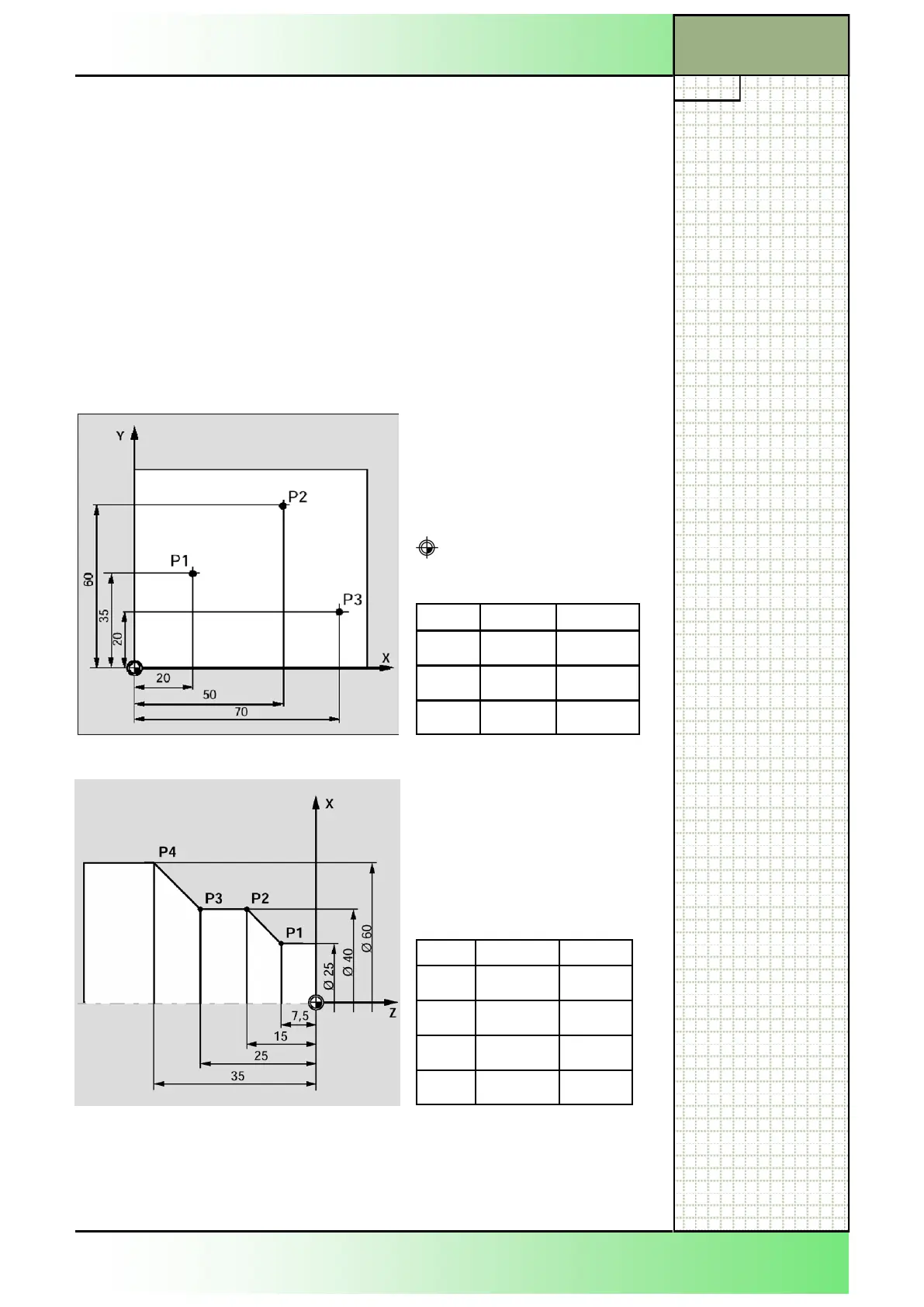

Absolute dimensioning: Code G90

All dimensions always refer to the active work piece zero point.

The absolute coordinates in a departure command describe the position,

to which the tool is to traverse.

G90 X Y

P1

20 35

P2

50 60

P3

70 20

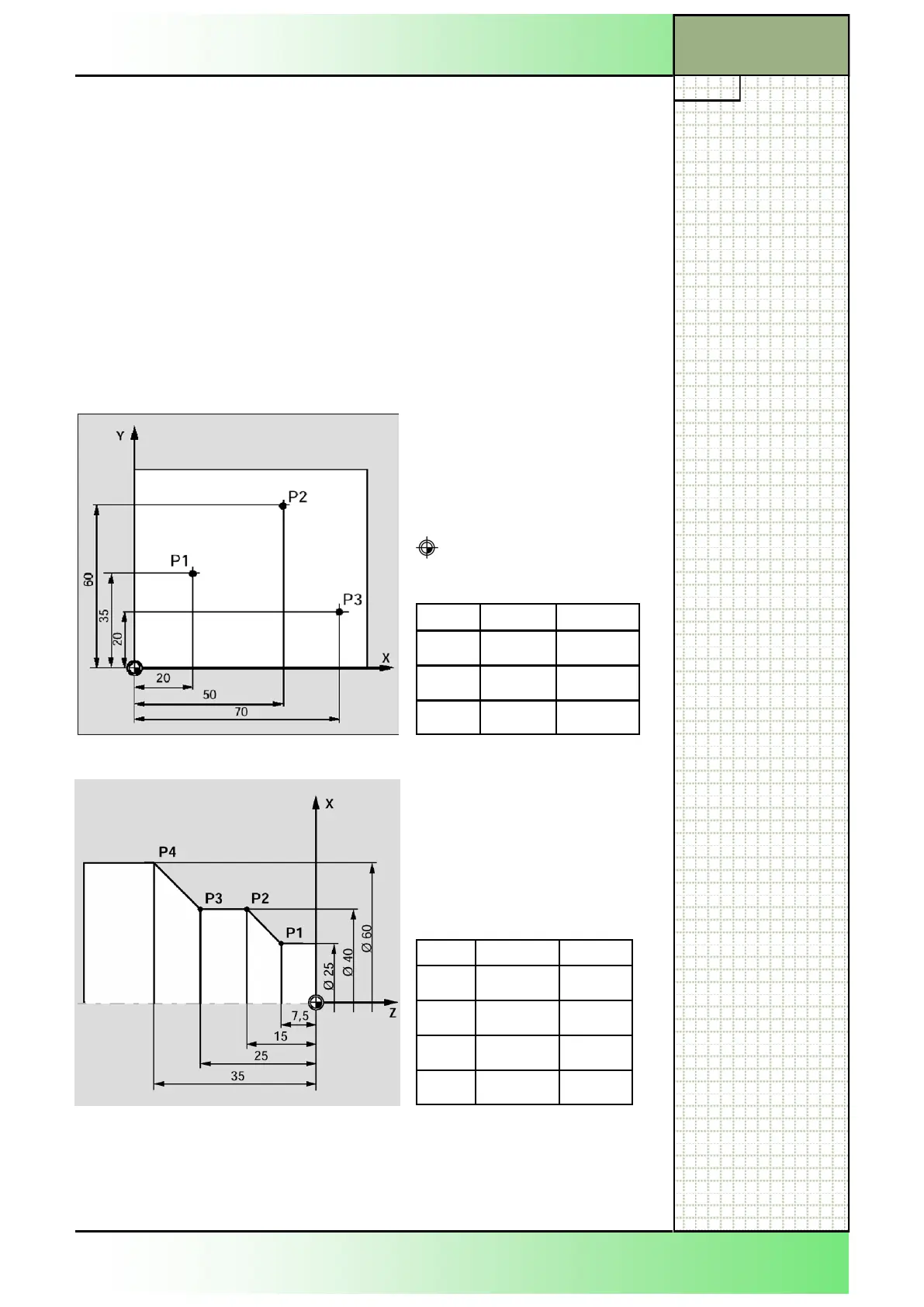

G90 X Z

P1

25 -7.5

P2

40 -15

P3

40 -25

P4

60 -35

Coordinates,

an example for milling:

Coordinates,

an example for turning:

(All X values are diameters,

DIAMON)

Code G90 is usually activated as machine status when switching ON.

It is modally active for all axes simultaneously and can be reset to incre-

mental dimensioning with G91.

2. 1 Absolute dimensioning

Workpiece zero point

Loading...

Loading...