throttle in the low position. Allow muffler manifold pressure from

the tank vent line to get fuel to the carburetor. Avoid “choking” fuel

through the line by placing your finger over the carburetor. With

properly broken-in engines, these procedures should work

perfectly every time.

2-STROKE ENGINES:

If you plan to use a 2-stroke engine, some basic openings in the

nose of the fuselage must be made to allow for muffler clearance

and mounting, as well as an exit hole for the needle valve. In

addition, if you plan to use a fuel filler valve, such as the Du-Bro

#334 Kwik-Fill Fueling Valve or some other type of fueling system,

this will be the time to install it. For reference, the engine shown in

the following assembly and installation steps is the Irvine .46,

typical of engines in the .40 class.

The fuselage has the throttle pushrod housing tube already

installed. However, this tube has not

been glued in place and is

removable. The firewall has been pre-drilled for installing the

throttle tube on either side of the firewall. This allows for the

different locations of various engine throttle arms, including

4-strokes. Before starting the engine installation, be sure the

throttle pushrod tubing is on the correct side of the firewall for your

particular engine. The remaining hole in the firewall can be filled

with a short piece of rounded balsa, sanded smooth and fuel-

proofed with thin CA, dope or epoxy resin.

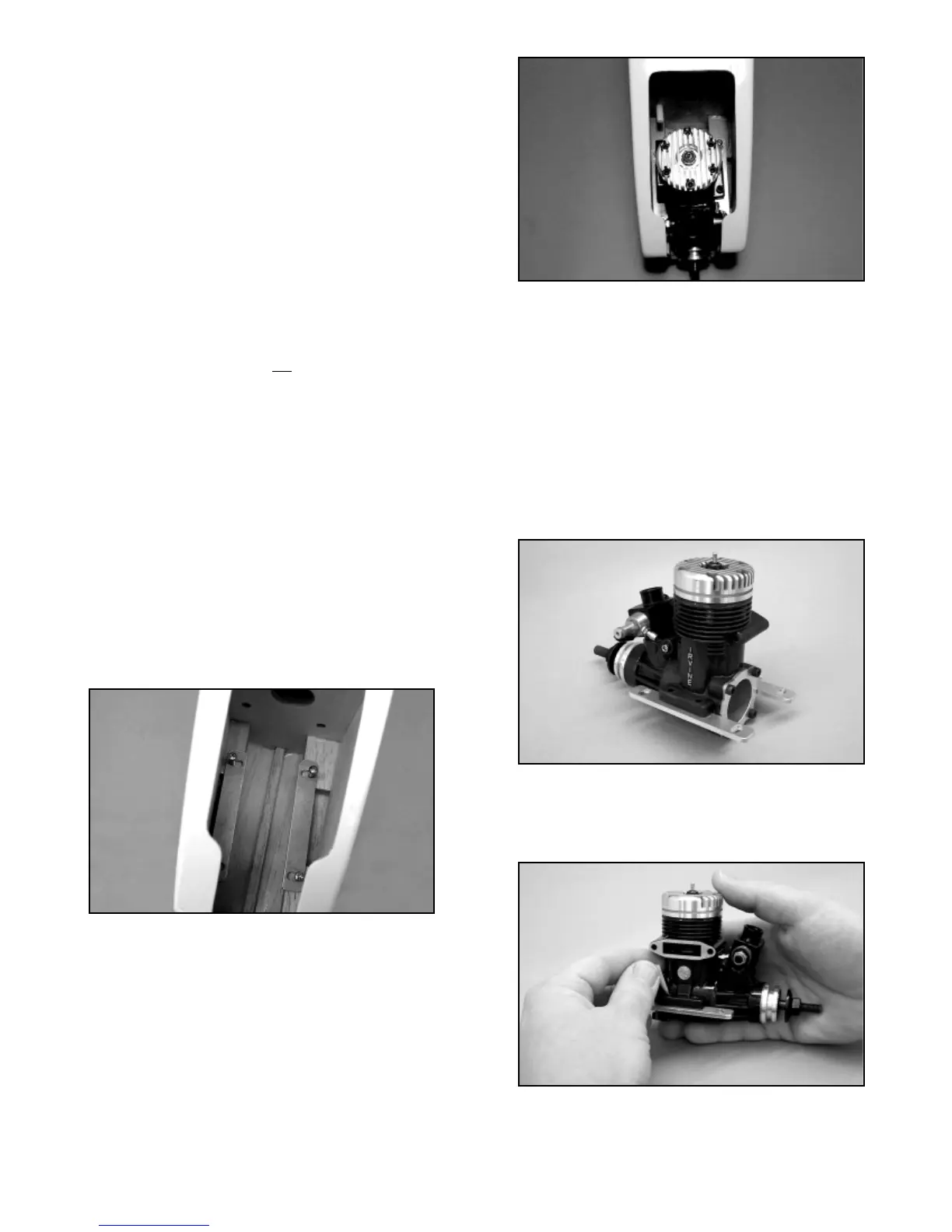

❑ 1) With the fuselage upside down on your workbench,

temporarily install the two aluminum motor mount rails onto the left

and right hardwood motor mount bearers in the nose of the

fuselage. Align the oblong holes over the pre-drilled bolt holes and

insert the four M3 x 20mm bolts with the large washers only (the

lock washers will only be used when the engine is final-mounted)

through the aluminum mount holes. Use a screwdriver to thread

the bolts in place but do not tighten them. The aluminum rails

should be just free enough to move.

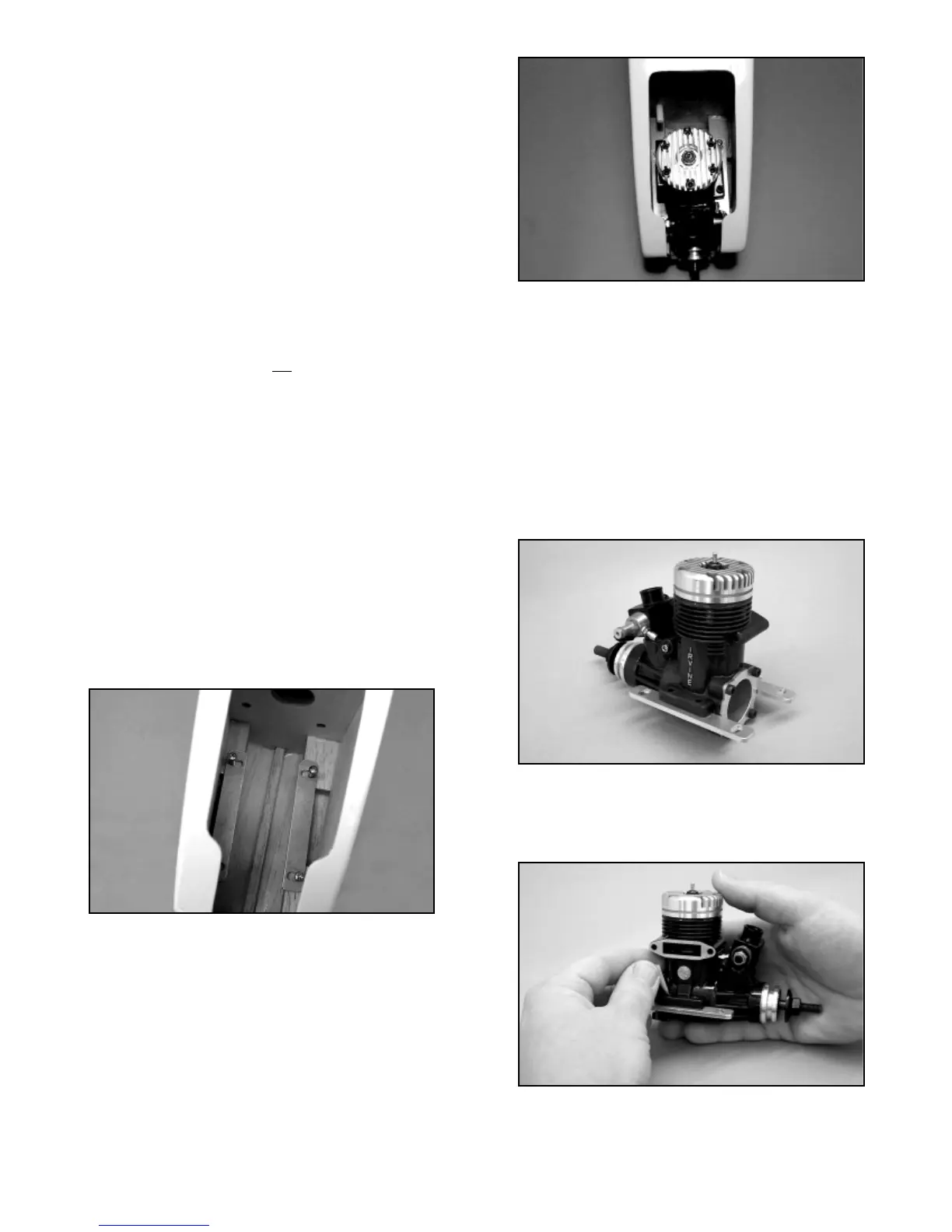

❑ 2) With the muffler and needle valve removed, fit your engine

in place between the aluminum rails, with its mounting lugs on top

of the rails. Slide the engine into its approximate mounting position

with the prop hub just ahead of the front of the fuselage by

approximately 1/16” - 3/32”. This spacing will be the clearance for

the spinner backplate (temporarily mounting the spinner backplate

to the engine and using 1/16” scrap balsa “spacers” makes this

spacing easy and accurate). Be sure the aluminum motor mount

rails are against the sides of the engine case and the engine is

centered at the front. With the engine and aluminum mounts now

in position, lightly tighten the four motor mount bolts to hold the

aluminum rails in place. Remove the engine.

❑ 3) Use alcohol or acetone to clean the bottom surfaces of the

engine mounting lugs, removing any oil or grease. Do the same

thing to the tops of the aluminum motor mounts, cleaning them

completely. Apply 3 or 4 drops of thin CA glue to the bottom of

each mounting lug on the engine. Carefully place the engine

back into the nose of the airplane, positioning it with the proper

1/16” - 3/32” clearance for the spinner backplate. Hold the engine

in place to the aluminum rails and use a little accelerator to set the

CA glue.

❑ 4) Loosen and remove the four bolts holding the aluminum

rails in place and carefully remove the engine, with the attached

aluminum rails, from the nose of the model.

❑ 5) Use a shortened pencil with a sharp point to mark the

locations of the engines mounting holes onto the aluminum motor

mounts. To remember which rail fits on the right and left side of the

engine, mark them with an “R” and “L” (left and right).

Tap the aluminum mounts to free them from the engine. Use the

pencil marks to drill clearance holes through both motor mounts

for the engine mounting bolts (not supplied). If you use typical

6-32 socket head bolts for mounting the engine, the holes should

7

Loading...

Loading...