mount it and make the required hole in the side of the fuselage for

the fueling probe. Locate the aluminum bracket to the firewall,

(with the fuel valve in place), and mark the approximate location of

the required opening in the fuselage side. Like the needle valve

opening, start with a small drilled hole and open it up to match the

center of the fueling valve.

❑ 9) The engine compartment was fuel-proofed at the factory.

However, the exposed wood edges of the muffler and needle valve

openings should now be coated to make them fuel proof as well.

We suggest using clear dope or epoxy resin to seal the exposed

wood. To make the job look totally complete and custom, try using

flat white or flat black dope or other fuel-proof paint.

❑ 10) The fuel tank can now be installed. Apply a bead of silicon

sealer around the neck of the tank and install it into the fuel tank

compartment, through the top of the fuselage. Press the neck into

the hole in the firewall. Included in the kit contents is a balsa piece

measuring 5/16” x 3/4” x 3-3/16”. This is used to hold the fuel tank

in place at the rear. Position the balsa retainer directly behind the

tank, between the fuselage sides. Apply a couple of drops of thin

CA glue to each side of the balsa piece to hold it in place. If for

any reason you need to remove the tank, the balsa piece can be

easily popped loose and tank removed.

❑ 11) Apply a little thread-locking compound to the threads of the

M3 x 20mm mounting bolts. Install the lock washers onto each

bolt, followed by the larger flat washers. Install the engine and

aluminum rails into the engine compartment. Slip the four bolts

(with washers) into the oblong holes in the aluminum rails. Thread

the bolts into their blind mounting nuts and tighten the bolts firmly

to the wood motor mounts - be sure to maintain the 1/16” - 3/32”

spinner backplate clearance. Use medium fuel tubing (not

supplied) to now make the required connections between the

engine and fuel tank and the vent line and muffler manifold

pressure nipple.

The throttle linkage will be made during the radio installation

phase of these instructions. This completes the engine and fuel

tank installation.

4-STROKE ENGINES:

Installing the typical .40 - .52 4-stroke engine is similar to installing

2-stroke engines. However, there are obvious physical differences

in the basic configurations of these engines, including totally

different carburetor, throttle arm, and muffler locations. For

reference, the engine shown in the following steps is a Magnum

®

XLFS .52AR 4-stroke, (to more easily install this particular engine,

we reversed the carburetor position 180

O

on the intake manifold).

The engine compartment in the Rascal Forty will accept virtually

any make of 4-stroke engines in .40 to .52 c.i. sizes.

As mentioned in the 2-stroke instructions, the fuselage comes with

the throttle pushrod housing tube installed, but not yet glued in

place. The firewall has already been pre-drilled to allow installing

this tube on either side. Before starting the engine installation, be

sure the throttle pushrod tubing is on the correct side of the firewall

for your particular engine. The unused hole can be filled with a

short piece of dowel and sanded smooth. It should then be fuel-

proofed with thin CA, dope or epoxy resin.

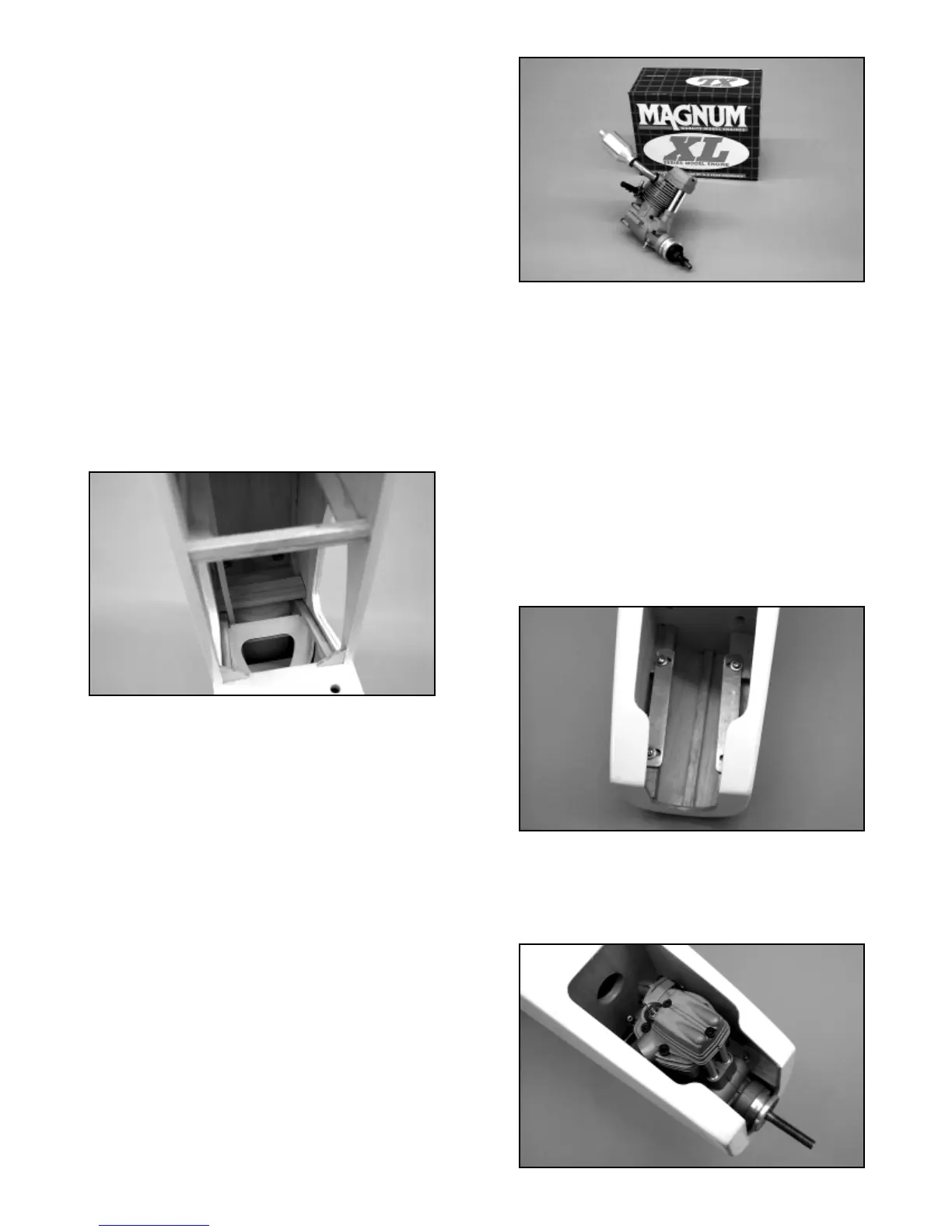

❑ 1) Place the fuselage upside down on your workbench and

temporarily install the two aluminum motor mount rails onto the

hardwood motor mount bearers built-in to the nose of the fuselage.

Align the oblong holes in the aluminum rails over the pre-drilled

holes in the wood bearers and insert the four M3 x 20mm bolts

with the larger washers only (the lock washers will only be used

when the engine is final-mounted) through the aluminum mount

holes. Use a screwdriver to thread the bolts in place but do not

tighten them. Leave the aluminum rails just free enough to move.

❑ 2) Remove the muffler header pipe and needle valve from the

engine. Fit the engine in place onto the aluminum rails. Slide the

engine to its approximate mounting position with the prop hub just

ahead of the front of the fuselage by approximately 1/16” - 3/32”.

This spacing will be the clearance for the spinner backplate

9

Loading...

Loading...