14

PART REMOVAL, REPLACEMENT & TOOL ADJUSTMENTS

The following procedure fully describes the disassembly of the PRHM-34. The instructions can

be reversed to assemble the tool. Please note that areas of the tool which require specific

adjustments for reassembly will be explained as well.

The disassembly instructions begin at a logical point for fully disassembling the tool, yet this is

not always necessary. Some disassembly procedures may be appropriately skipped in order to

avoid unnecessary labor.

Use the following instructions to disassemble the PRHM-34:

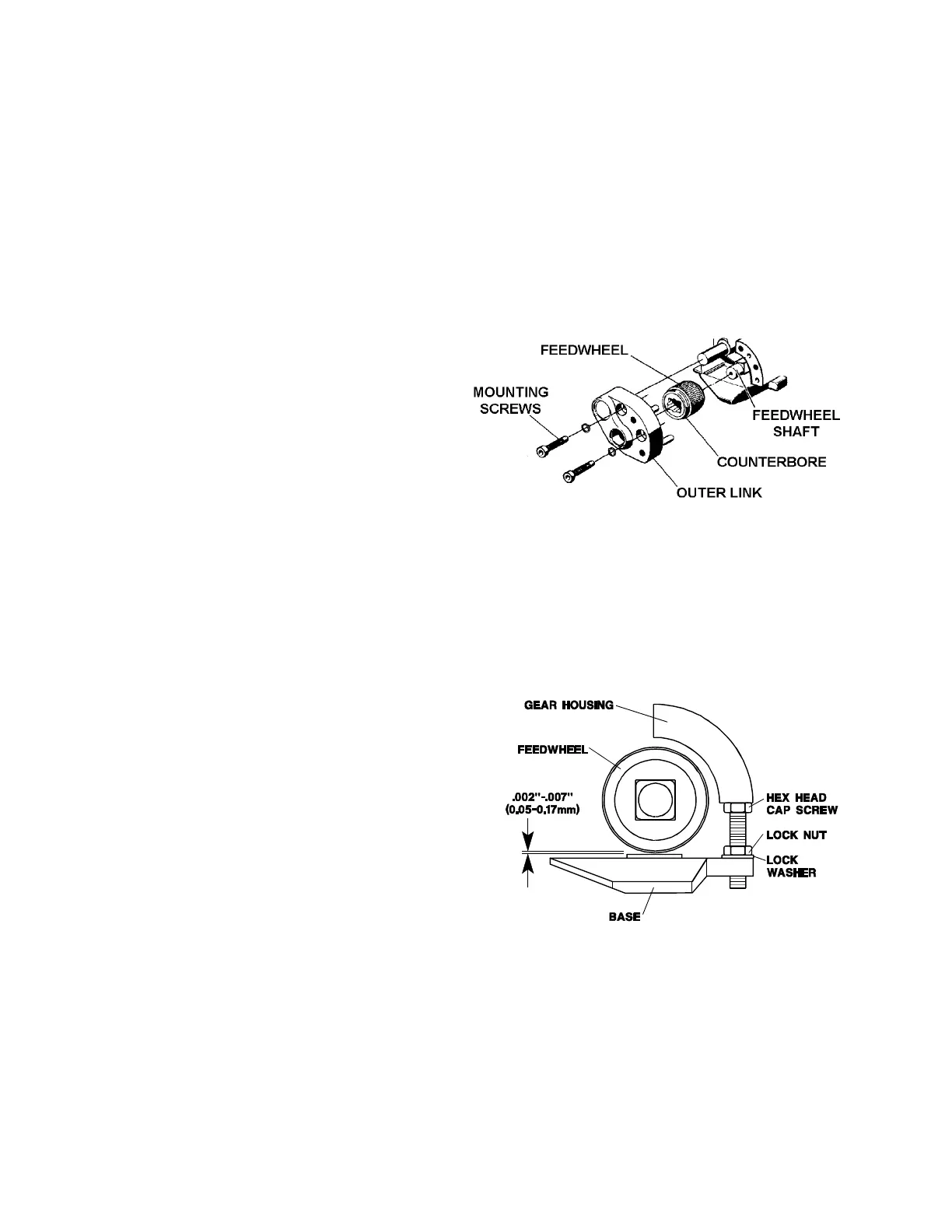

STEP 1 - FEEDWHEEL (For additional part information see pages 22 & 23)

1. To replace the feedwheel, remove the two

socket head cap screws which secure the

outer link. Remove the outer link from

the gear housing. Slide the feedwheel off

the feedwheel shaft. The counterbore

face of the feedwheel must face the outer

link in order to match up with the flange

bushing in the outer link.

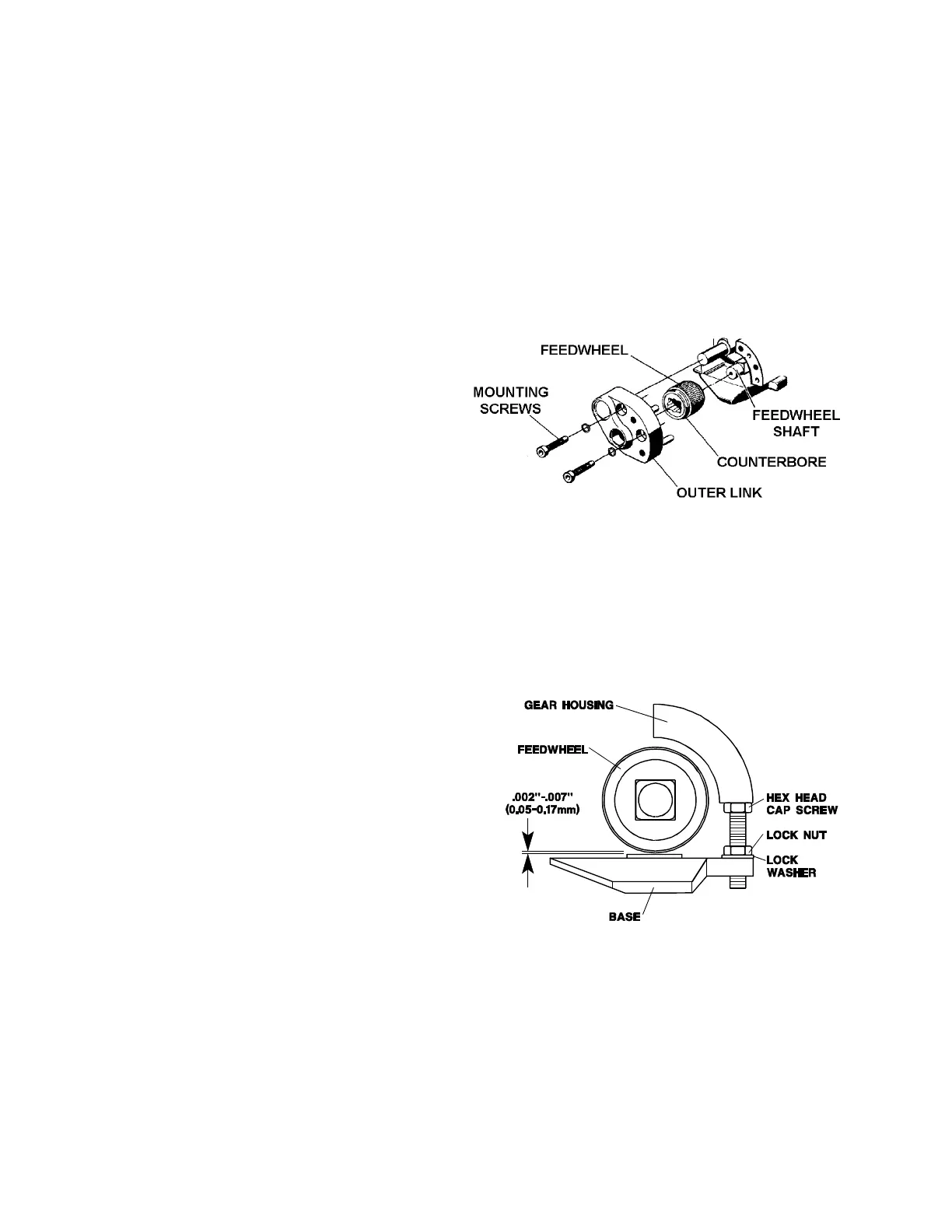

2. Replace the feedwheel in the same manner in which it was removed. Feedwheel clearance

should be checked after replacing any parts associated with the tensioning system. This

clearance should be maintained to prevent the feedwheel from touching the wear pad and

encouraging early failure of these parts.

Feedwheel clearance can be set as follows:

a. Loosen the lock nut which secures the hex head adjustment screw which controls

feedwheel clearance.

b. Feedwheel clearance should be adjusted to

.002"-.007" (0.05mm-0.17mm) clearance.

Place an appropriate feeler gauge between

the feedwheel and the wear plug, turn the

hex head screw until the proper feedwheel

clearance has been reached.

c. When the clearance has been set, secure the hex head screw with the lock nut. Recheck

feedwheel clearance and adjust if necessary.

Loading...

Loading...