69

EN

4.4 MAINTENANCE

To guarantee functioning and efficiency of

the appliance, in respect of the legal provi-

sions in force, it must be regularly checked;

the frequency of the checks depends on the

type of appliance and the installation and

usage conditions.

In any case, it should be inspected at least

once a year by a qualified technician.

Carry out the cleaning of the generator in

the following way:

– Turn the main switch off to stop electric

power reaching the boiler and close the

gas feed cock.

– Remove the outer casing and the gas

burner manifold unit. To clean the burner,

blow in a jet of air, so as to remove any

dust particles that may have accumula-

ted.

– Clean the heat exchanger, removing any

dust or residue from combustion. When

cleaning the heat exchanger or the bur-

ners, chemical products or steel brushes

MUST NOT BE USED.

Make sure that the tops of the burners

with the holes are free from encrusta-

tions.

– Reassemble the items removed from the

boiler, making sure to follow the correct

sequence.

– Check operation of the main burner.

– After assembly of all the gas connections,

these must be tested for soundness,

using soapy water or appropriate pro-

ducts. DO NOT USE NAKED FLAMES.

– Do not use calcium chloride to treat

the plastic component during generator

maintenance.

4.4.1 Chimney sweep function (fig. 22)

To check boiler combustion, press the

installer’s key

for a few seconds.

The chimney sweep function will switch on

and will continue for 15 minutes. From that

moment, the boiler will start working in hea-

ting mode at maximum power, with cut off

at 80°C and re-ignition at 70°C.

Before activating the chimney sweep fun-

ction make sure that the radiator valves

or eventual zone valves are open.

The test can also be carried out with the

boiler working in D.H.W. mode.

For this, after activating the chimney sweep

function, open one or more hot water fau-

cets. Under these conditions, the boiler

will function at maximum power with the

D.H.W. kept at between 60°C and 50°C.

During the test, the hot water faucets must

remain open.

If the key

and

are pressed during the

15 minutes of the chimney sweep function,

the boiler will be brought respectively to

maximum and minimum power.

The chimney sweep function will automati-

cally switch off after 15 minutes or when

the key

is pressed again.

4.4.2 Cleaning the filter “Aqua Guard

Filter System” (fig. 23)

To clean the filter, close the delivery/return

on/off taps, turn off the power to the con-

trol panel, remove the casing and empty the

boiler using the drain provided.

Place a container for collection underneath

the filter, unscrew the cap and proceed to

clean the filter, removing impurities and

limestone deposits.

Check the seal o-ring before reassembling

the cap with the filter.

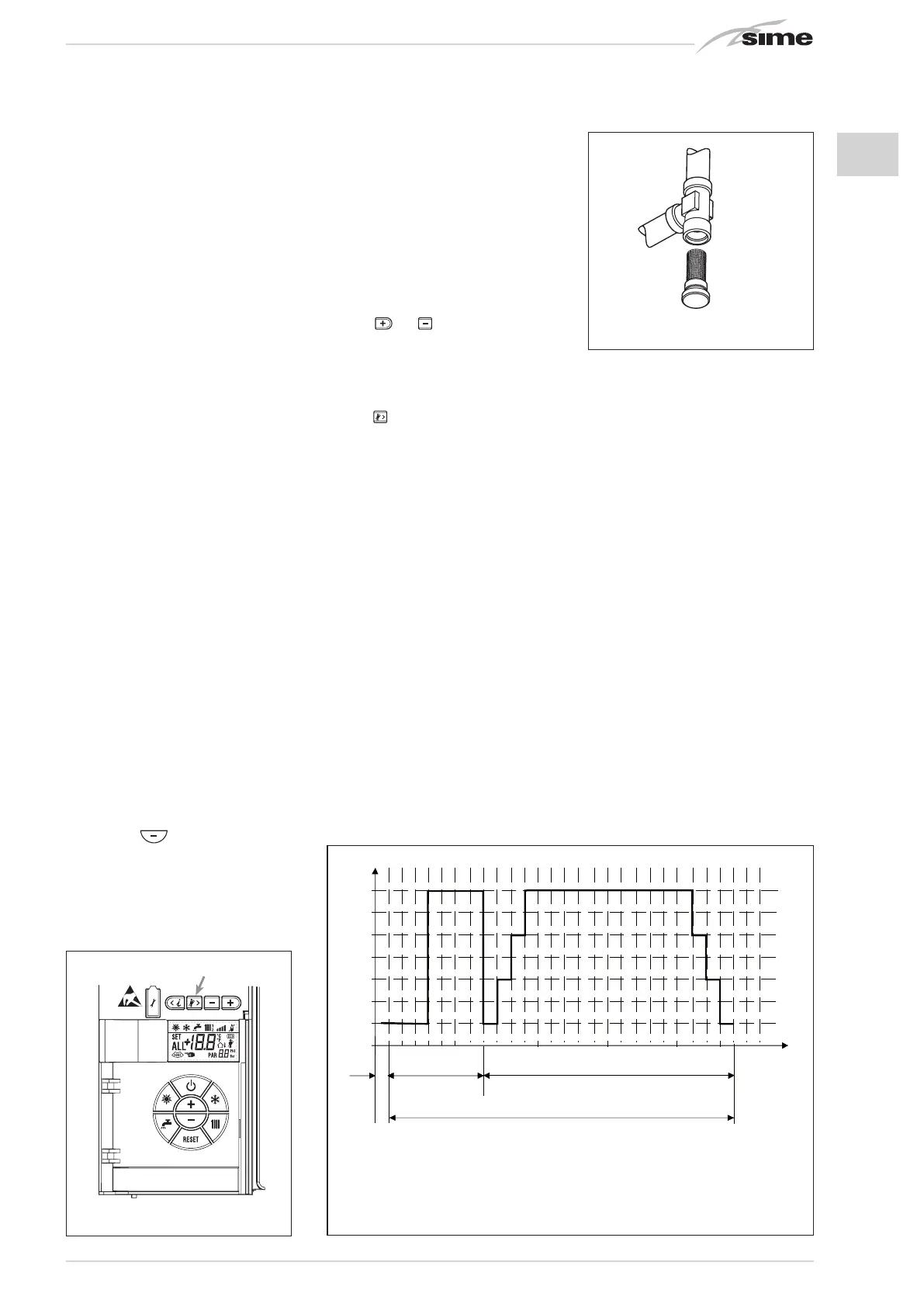

4.4.3 Operation floor drying (fig. 23/a)

The operation floor drying keeps the floor at

a pre-established temperature profile and

it is activated only for those systems com-

bined with the mixed zone card ZONA MIX

code 8092234. The temperature profiles

can be selected by means of the installer

parameter PAR 43:

0 = Not activated function

1 = Curve setting A

2 = Curve setting B

3 = Curve setting A + B

The turning off of the function happens cli-

cking on the button OFF (return of PAR 43

to the value 0) or automatically at the end

of the function.

The set of the mixed zone follows the deve-

lopment of the selected curve and reaches

a maximum of 55°C. During the function

all the other heating demands are ignored

(heating, sanitary, antifreeze and chimney

sweep).

During the functioning the display shows

the remaining days for the completion of

the function (example mains digits -15 =

15 days lack to the end of the function). The

diagram fig. 23/a reports the development

of the curve.

ATTENTION:

- Observe the relevant standards and

regulations of the floor manufacturer!

- Proper functioning is ensured only

when the plant is correctly installed

(hydraulic system, electrical installa-

tion, settings)! If not observed, the floor

might get damaged!

Fig. 23

Apre

2

2

2

Circuito

riscaldamento 2

Circuito

riscaldamento 3

(impianto tre

zone)

Fig. 22

50

45

40

35

30

20

5101518

[Tag

]

0

25

55

AB

11

57

X

A + B

1 25

[TVw]

Fig. 23/a

TVw Flow temperature setpoint

Tag Period in days

x Start day

A Functional heating

B Floor curing heating

Loading...

Loading...