The boiler should be installed in a fixed

location and shall be carried out only by

specialized and qualified firms in com-

pliance with all instructions contained

in this manual.

2.1 BOILER ROOM

AND VENTILATION

There are no particular regulations to

follow with reference to the boiler

room because “RX 19-26” boilers,

which do not exceed the 35 kW limit,

can be installed in rooms that are suf-

ficiently ventilated.

The rooms where the gas-fired

systems are installed must receive at

least the quantity of air necessary for

the normal combustion of the gas used

by the various installations.

Therefore, to ensure the air circulation

in the rooms, it is necessary to make

some holes in the walls.

These holes must have the following

characteristics:

– Have e total free surface of mini-

mum 6 cm

2

for each kW of thermal

capacity, for a minimum of 100 cm

2

.

–

They must be located as close as

possible to floor level, not prone to

obstruction and protected by a

grid which does not reduce the

effective section required for the

passage of air.

The “RX 37÷55” models with a capa-

city exceeding 35 kW shall instead be

installed in a boiler room that meets

the existing safety regulations for

network gas-fired heating systems,

where minimum distances must be

observed.

2.2 BOILER CONNECTION

Before connecting the boiler circulate

some water in the pipes to eliminate

any foreign bodies which may prevent

the equipment from working properly.

When making the hydraulic connec-

tions, follow the instructions of fig. 1

carefully.

Connections shall be easily disconnec-

ted by means of unions with revolving

fittings. It is always advisable to mount

suitable interception gate valves on the

C.H. flow and C.H. return plant pipes.

The gas connection must be made

43

GR

RO

RUS

SCG

IT

ES

PT

GB

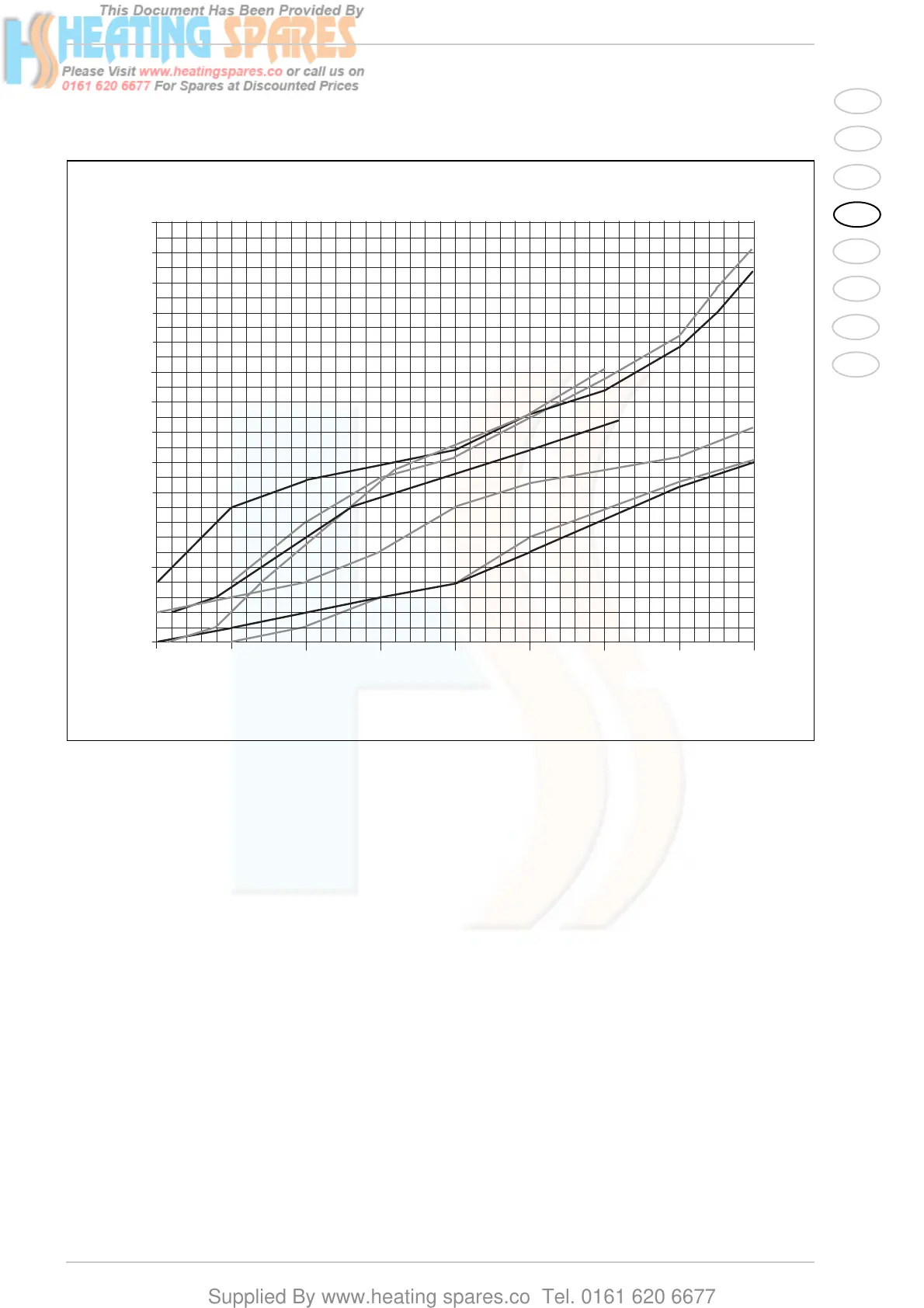

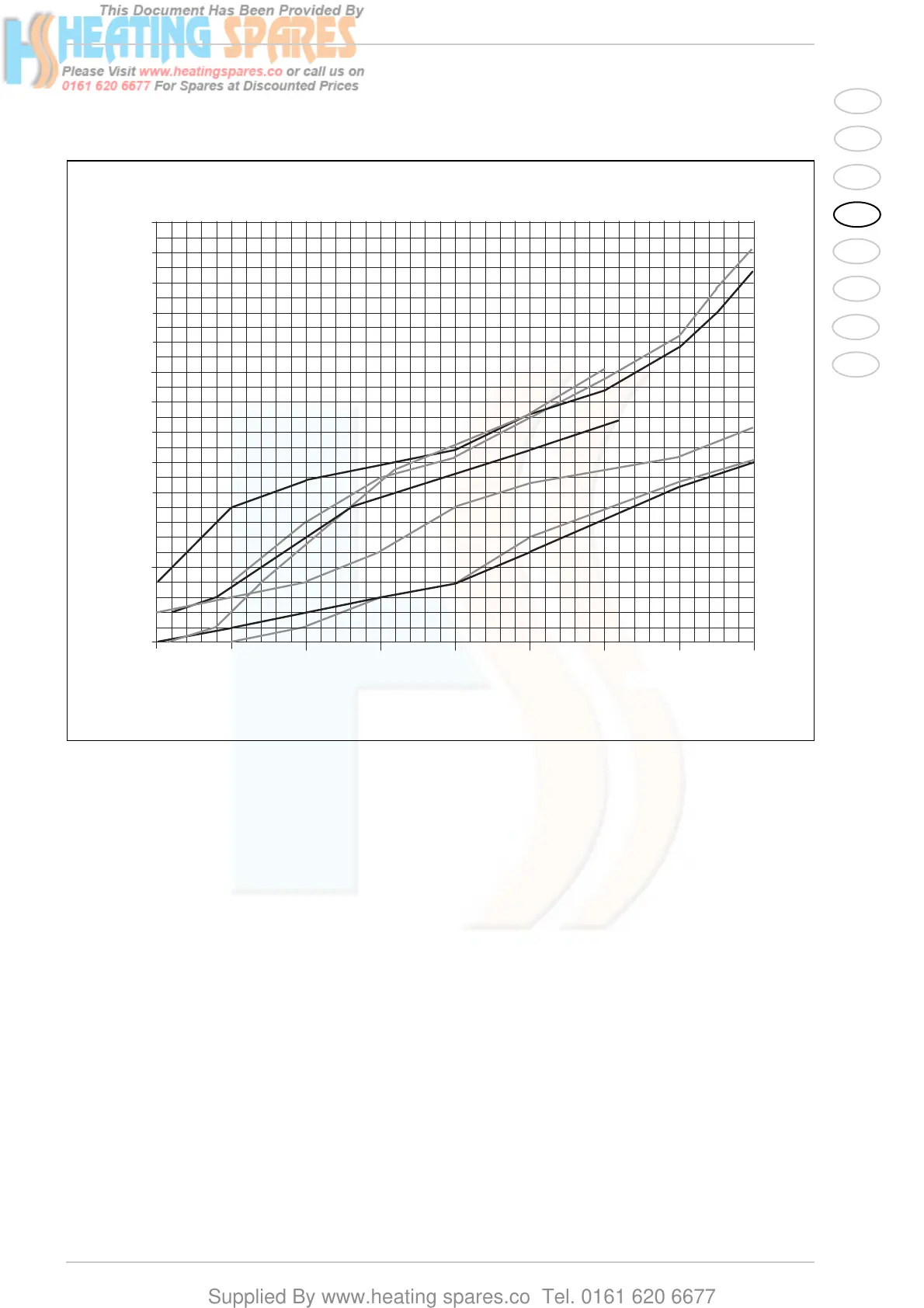

1.5 BOILER CIRCUIT LOAD LOSS

Fig. 2/a

Loading...

Loading...