The boiler should be installed in a fixed location and shall

be carried out only by specialized and qualified firms in

compliance with all instructions contained in this manual.

2.1 BOILER ROOM

There are no particular regulations to follow with referen-

ce to the boiler room because “RX 19-26” boilers, which

do not exceed the 35 kW limit, can be installed in rooms

that are sufficiently ventilated.

The “RX 37÷55” models with a capacity exceeding 35 kW

shall instead be installed in a boiler room that meets the

existing safety regulations for network gas-fired heating

systems, where minimum distances must be observed.

2.2 VENTILATION REQUIREMENTS

The rooms where the gas-fired systems are installed must

receive at least the quantity of air necessary for the nor-

mal combustion of the gas used by the various installa-

tions. Therefore, to ensure the air circulation in the rooms,

it is necessary to make some holes in the walls. These

holes must have the following characteristics:

− have e total free surface of minimum 6 cm

2

for each kW

of thermal capacity, for a minimum of 150 cm

2

(if

necessary, these holes can be obtained by increasing

the space between the door and the floor).

− be on the lower part of an external wall, preferably

facing the one with the burnt gas discharge.

2.3 BOILER CONNECTION

Before connecting the boiler circulate some water in the

pipes to eliminate any foreign bodies which may prevent

the equipment from working properly. When making the

hydraulic connections, follow the instructions of fig. 1

and 2 carefully. The boiler connections shall be made by

using rigid pipe fittings or steel flexible pipes that do not

cause any stress on the installation.

Connections shall be easily disconnected by means of

unions with revolving fittings. It is always advisable to

mount suitable interception gate valves on the C.H. flow

and C.H. return plant pipes.

The gas pipe connection shall be made with weldless

galvanized steel pipes (Mannesmann type) with threa-

ded and lined joints, and using three-piece pipe fittings

only for initial and end connections. Pipes inside walls

shall be covered by a suitable sheath. The size of gas

pipes from the meter to the boiler will depend on both

the volume capacity (consumption) expressed in m

3

/h

and the gas density.

The installation pipe sections must be such as to ensu-

re the supply of the quantity of gas necessary to meet

the maximum requirements, keeping the loss of pressu-

re between the meter and any equipment. The door car-

ries on the inside an adhesive plate with the technical

specifications and the type of gas suitable for the boiler.

2.4 FLUE CONNECTION

A flue for the discharge into the atmosphere of the pro-

ducts of combustion of natural draught plants must have

the following characteristics:

− be sealed against the products of combustion, water-

proof and insulated;

− be made of materials capable of withstanding normal

mechanical stresses, heat and the action of the pro-

ducts of combustion and their condensate;

− be vertical and with no narrowing throughout its whole

length;

− be properly insulated to avoid flue gases condensing

or cooling, especially if it is placed outside a building

or in rooms with no heating;

− be kept at a safe distance from combustible and

easily inflammable materials by an air space or any

other suitable insulating material;

− have a chamber collecting solid materials and con-

densates below the mouth of the first flue; this cham-

ber must be at least 500 mm high.

Access to this chamber must be ensured through a

hole with an airtight metal door;

− its inner section must be round, square or rectangular;

if it is square of rectangular, the corners must be

round and have a radius of 20 mm minimum; however,

hydraulically equivalent sections are also permitted;

− be topped by a chimneypot having its outlet outside

the reflux area in order to avoid back pressures which

may obstruct the free discharge of flue gas into the air;

− there must be no mechanical suction equipment at the

top of the pipe;

− there must be no overpressure in stacks placed insi-

de or adjacent to inhabited rooms.

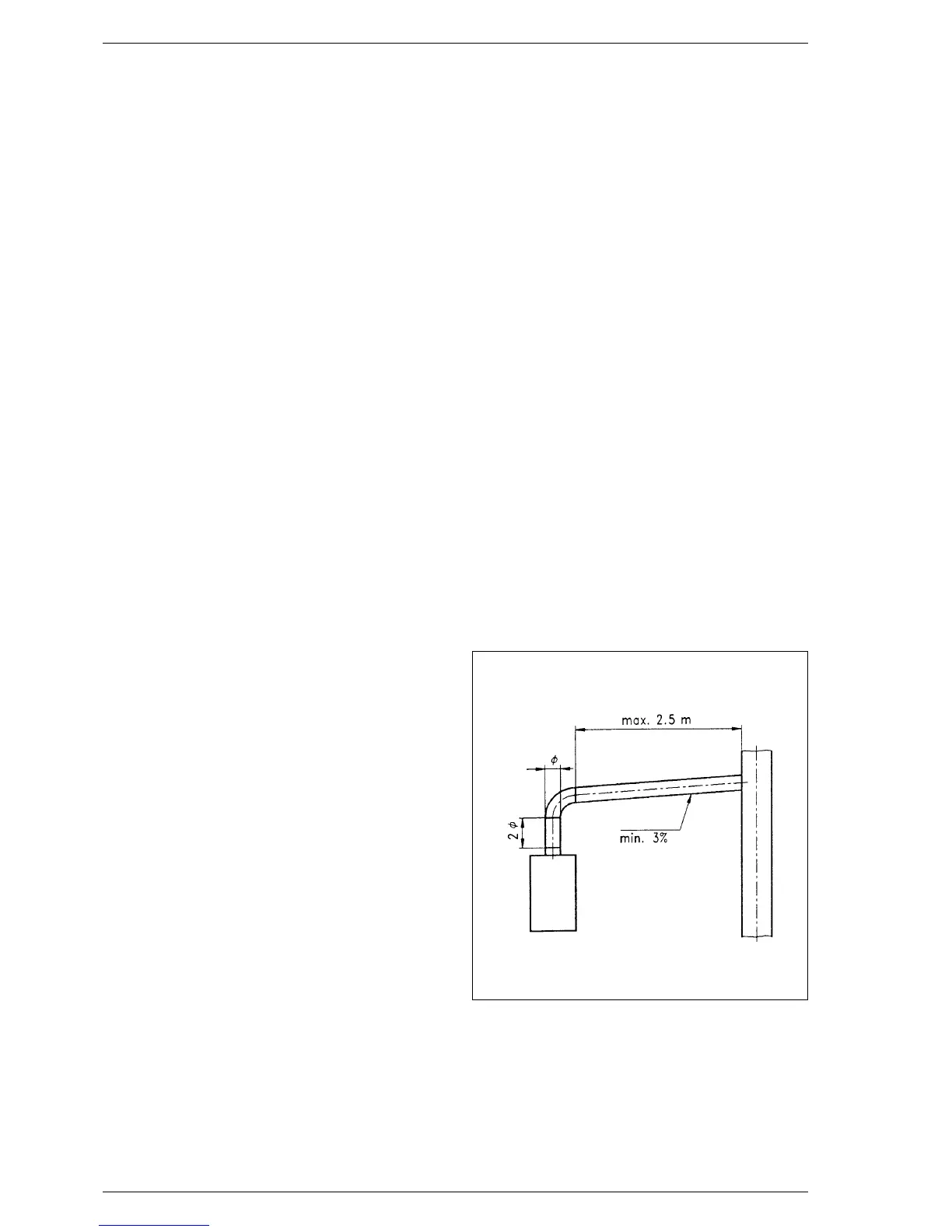

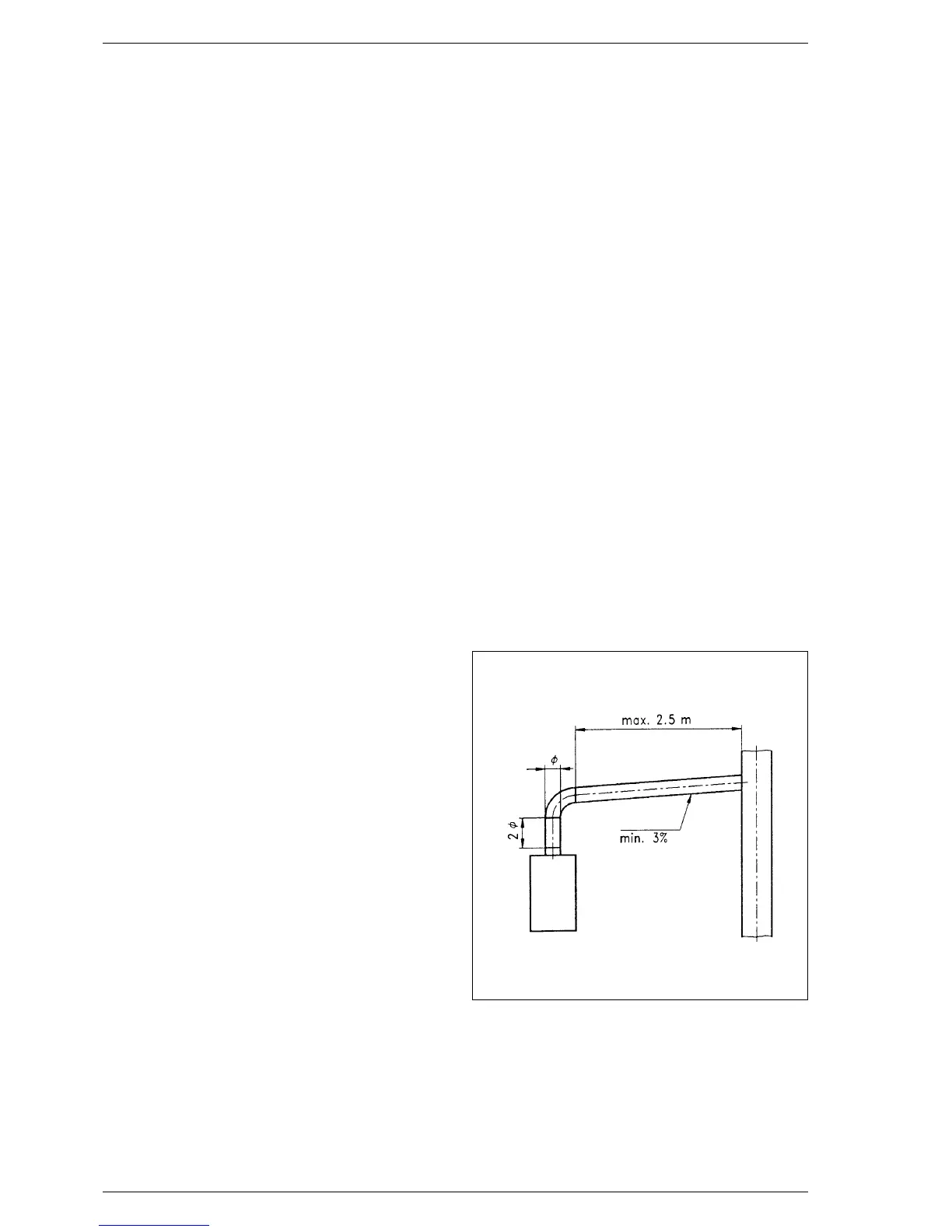

Fig. 6 refers to the boiler connection to the flue or to the

stack through flue ducts. In making the connection

observe the dimensions given and use sealing materials

capable of withstanding mechanical stresses and flue

heat over time. At any point of the flue the burnt gas tem-

perature shall not exceed the dew point temperature.

Maximum three changes of direction can be made, inclu-

ding the union to the stack/flue. For changes of direction,

use only curved components.

5

2 General instructions for the installation

Fig. 6

Gradient

Loading...

Loading...