7

2. Operate pump handle to deliver hydraulic power to the

system.

3. Change valve lever positions as needed.

Operate a double-acting cylinder only when

both hoses are connected to the pump and the cylinder. If

one hose is disconnected, the circuit will become blocked

and over pressurization of the hydraulic circuit could occur.

Serious personal injury or damage to equipment or

property could result.

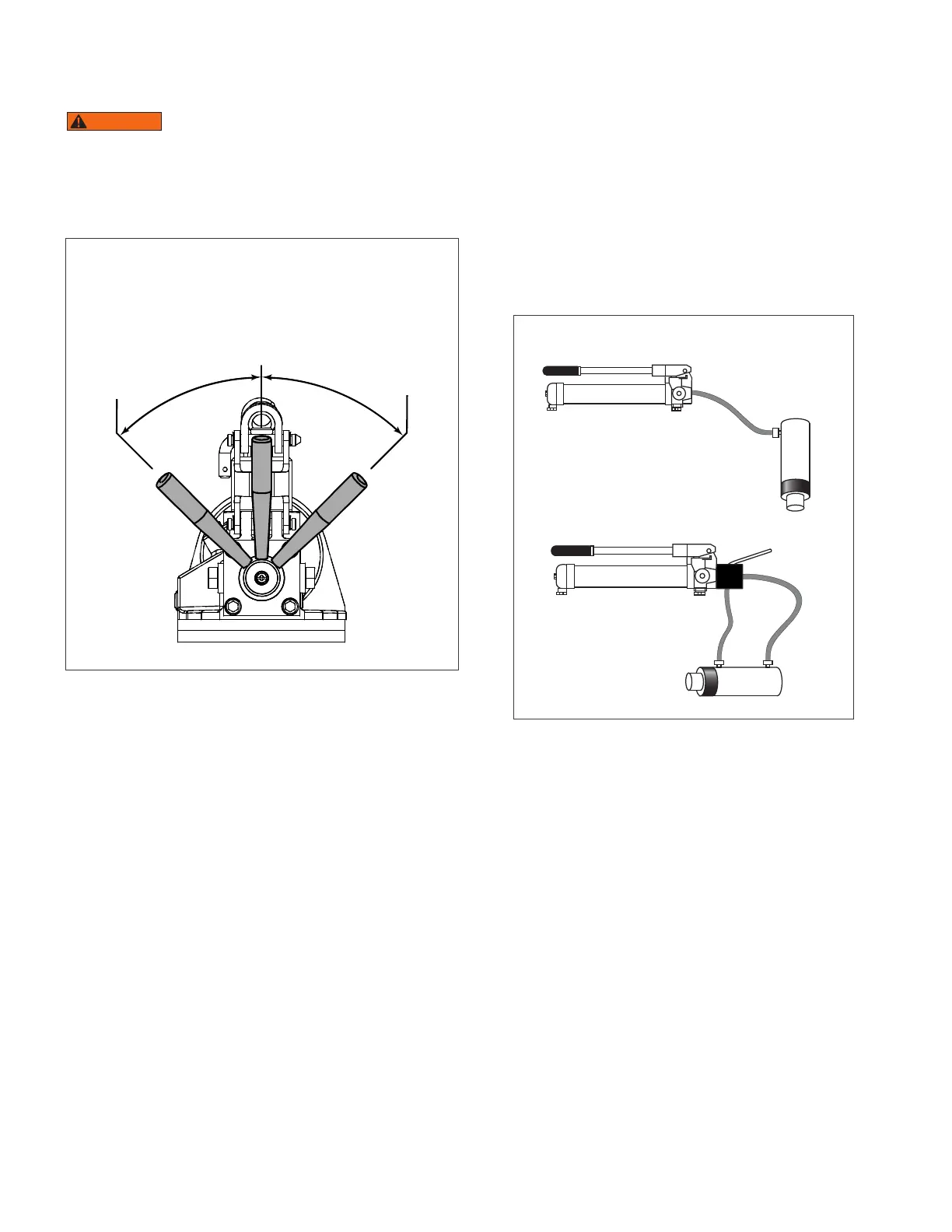

Figure 3B

Valve Positions - Models P140D, P143D,

P300D & P301D

Advance

Neutral

Retract

4.6 Air Removal

Removing air from the hydraulic system will help the

cylinder to advance and retract smoothly. Refer to the

procedure in the following steps:

1. On pumps with non-vented reservoirs, loosen the oil

fill plug. On pumps with vented reservoirs, loosen the

vent screw or petcock.

2. • Single-acting pump models: Close the release valve

or move the control valve lever to the advance position.

• Double-acting pump models: Move the control valve

lever to the advance position.

3. Position the hand pump at a higher elevation than the

cylinder.

4. For single-acting pump models, position cylinder with

the hydraulic port end located higher than the moving

end. For double-acting hand pump models, position

cylinder so that the hydraulic ports are facing upward.

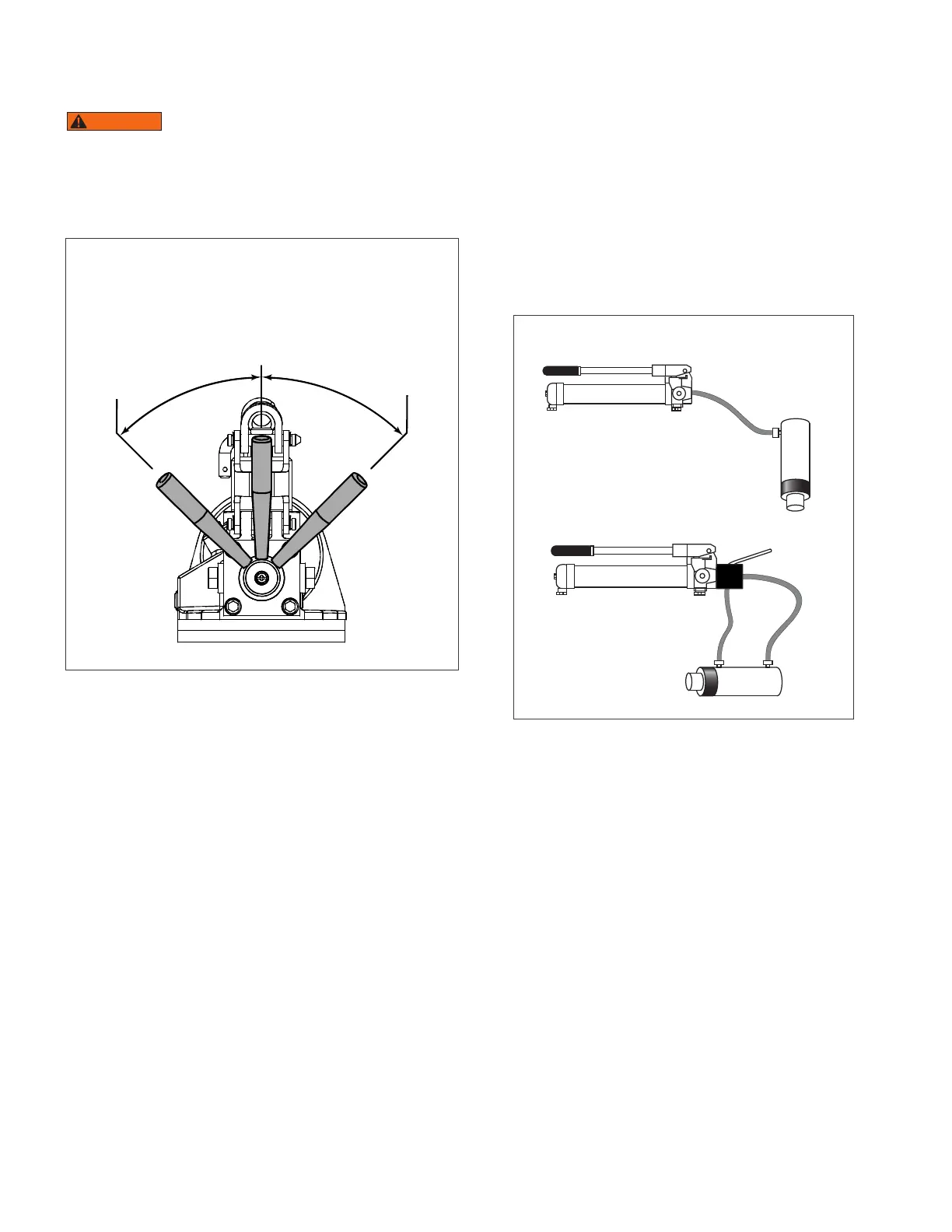

Refer to diagrams in Figure 4 for reference.

Note: Operate pump handle as required during the

following steps.

5. • Single-acting pump models: Fully advance the

cylinder. Then open the release valve or move the

valve lever to the retract position to retract the cylinder.

• Double-acting pump models: Fully advance the

cylinder. Then move the control valve to the retract

position and fully retract the cylinder.

6. Repeat steps 2 through 5 as necessary until all of

the air is expelled from pump’s hydraulic circuit and

cylinder motion is smooth and responsive with each

stroke of the pump handle.

Air Removal

Single-acting

Double-acting

Figure 4

4.7 Pressure Relief Valve

All pumps contain a factory set relief valve to prevent

over-pressurization. Do not attempt to readjust, disable or

modify this valve.

5.0 MAINTENANCE

5.1 Hydraulic Reservoir

Check oil level regularly. Drain oil and refill with Simplex

hydraulic oil every 12 months. If pump is used in dirty

environments, change the oil more often.

Use only genuine Simplex hydraulic oil or a comparable

high quality ISO 32 hydraulic oil having the same technical

characteristics.

The use of any other fluid could damage the seals or

equipment and will make the product warranty null and

void.

Loading...

Loading...