8

6.0 TROUBLESHOOTING

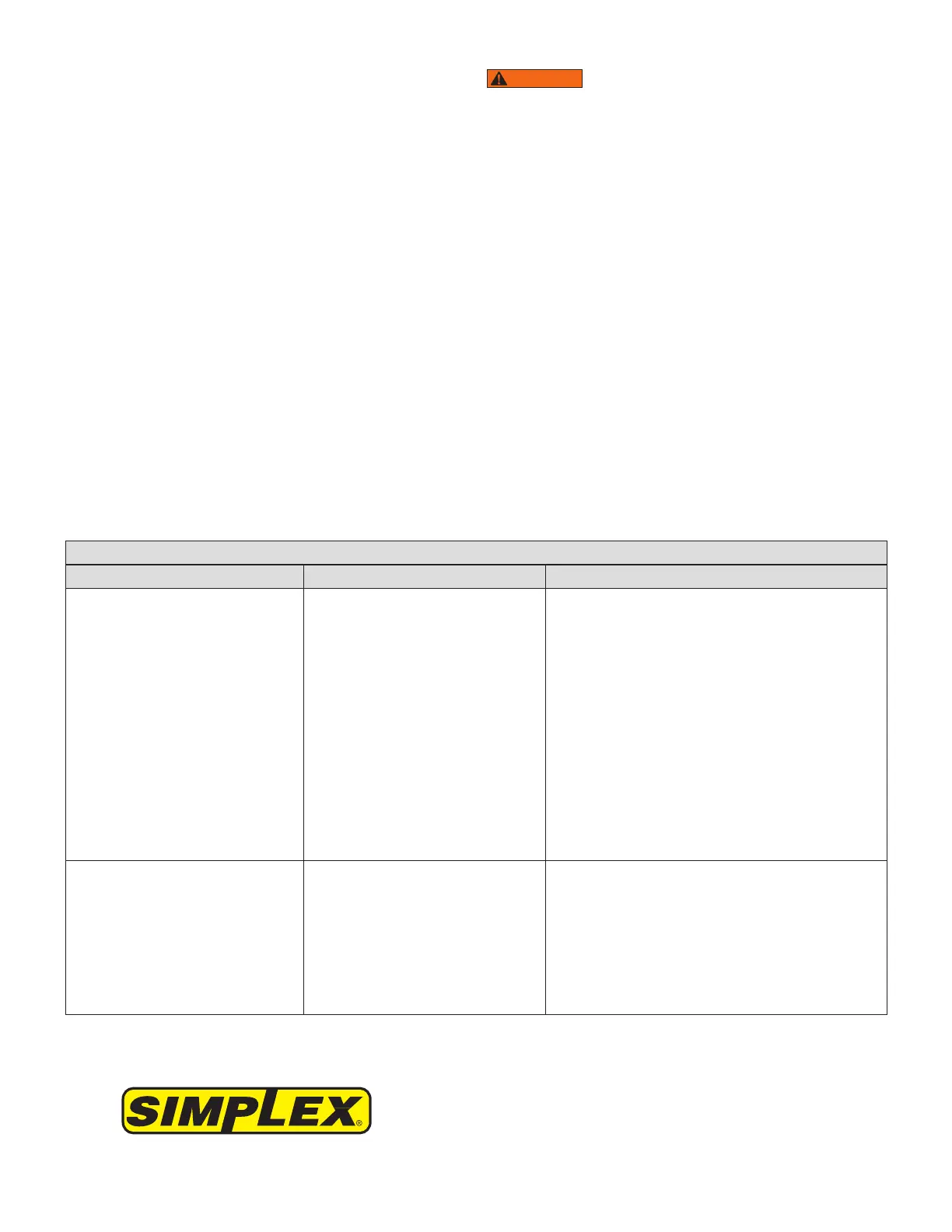

Table 3 - Troubleshooting Guide

Problem Possible Cause Solution

Cylinder does not advance. Oil level in pump reservoir is low.

Release valve is open

(if equipped).

Loose hydraulic coupler.

Load is too heavy.

Air trapped in system.

Cylinder plunger binding.

Add oil according to the maintenance

instructions.

Close the release valve.

Check that all couplers are fully tightened.

Do not attempt to lift more than rated tonnage.

Remove air according to instructions.

Check for damage to cylinder. Have cylinder

serviced by a qualified hydraulic technician.

Cylinder advances, but does not

hold pressure.

Leaking connection.

Leaking seals.

Internal leakage in pump.

Check that all connections are tight and leak

free.

Locate leak(s) and have equipment serviced by

a qualified hydraulic technician.

Have pump serviced by a qualified hydraulic

technician.

5.2 Oil Fill Information

Important: Non-vented reservoirs have a predetermined

oil level that should not be exceeded. Refer to Table 1 in

Section 2.0 for oil capacities. Never fill a pump beyond

the maximum oil level or capacity recommended by the

manufacturer.

• Non-vented hand pumps require some air in the reservoir

to function properly. A non-vented reservoir should never

be completely filled. If the reservoir is completely filled,

a vacuum will form, preventing proper operation of the

pump.

• Vented hand pumps can be filled up to the bottom of

the oil fill hole. However, it is recommended to leave a

small air gap to allow optimum functioning of the venting

system.

• Models P230, P230D, P461 and P461D must be filled to

within 1 inch [25 mm] of the top plate.

5.3 Adding Oil to the Pump

WARNING

Always add oil with cylinders fully retracted

(extended if pull cylinders) or the system will contain more

oil than the reservoir can hold.

Add oil as described in the following steps:

1. Remove oil fill plug from reservoir.

2. Determine if your pump has a vented or non-vented

reservoir. Refer to Table 2 earlier in this manual.

3. Add oil to the reservoir as required. Refer to oil fill

information in Section 5.2.

4. Reinstall oil fill plug after adding oil.

5. Remove air from system if necessary, as described in

Section 4.6.

6. Recheck oil level after removing air.

5.4 Keeping Oil Lines Clean

When coupler halves are disconnected, always install

dust caps. Use every precaution to guard unit against the

entrance of dirt, because foreign matter may cause pump,

cylinder, or valve failure.

N86 W12500 Westbrook Crossing

Menomonee Falls, WI 53051

Phone: 1 (262) 293-1575

Fax: 1 (262) 597-1127

Toll Free: 1 (800) 323-9114

www.tksimplex.com

Loading...

Loading...