12

4 DAY TANK OPERATION

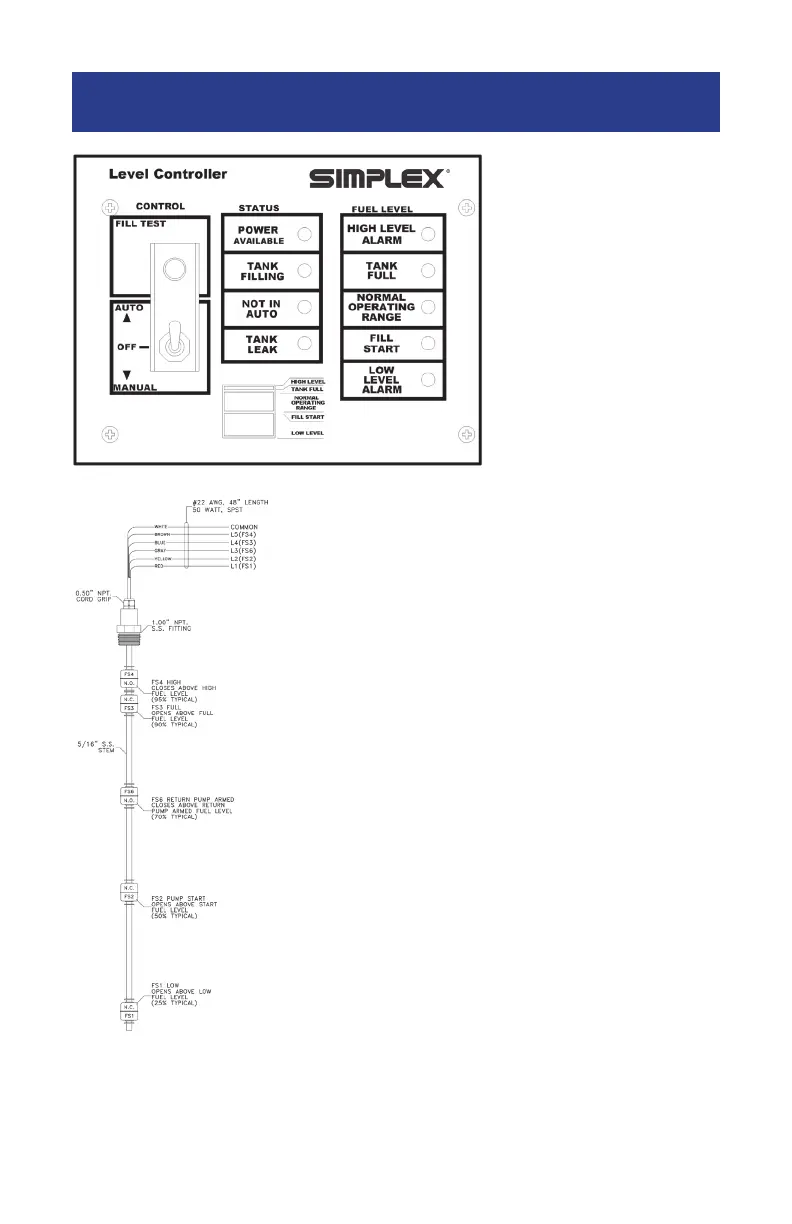

e control nameplate

consists of a durable,

fuel oil resistant, Lexan

membrane which contains

the Day Tank control

pushbutton, switch and

status indicators. e

control panel contains a

Fill Test pushbutton (hold

to test L.E.D. lamps), a

three position Day Tank

Auto-O-Manual switch,

and the following L.E.D.

lamps: Power Available,

Tank Filling, Tank Leak, Not In Auto (blinking),

High Level Alarm, Tank Full, Normal Operating

Range, Fill Start, and Low Level Alarm. Day Tank

operation is represented by the diagram in the lower

center of the nameplate.

e Day Tank control circuitry contains the fol-

lowing serviceable components: motor starting

contactor, and control fuses. Control fuses are 2A,

250VAC, ABC type, and the standard motor starting

contactor is a double pole, 24VDC coil, rated at 20A.

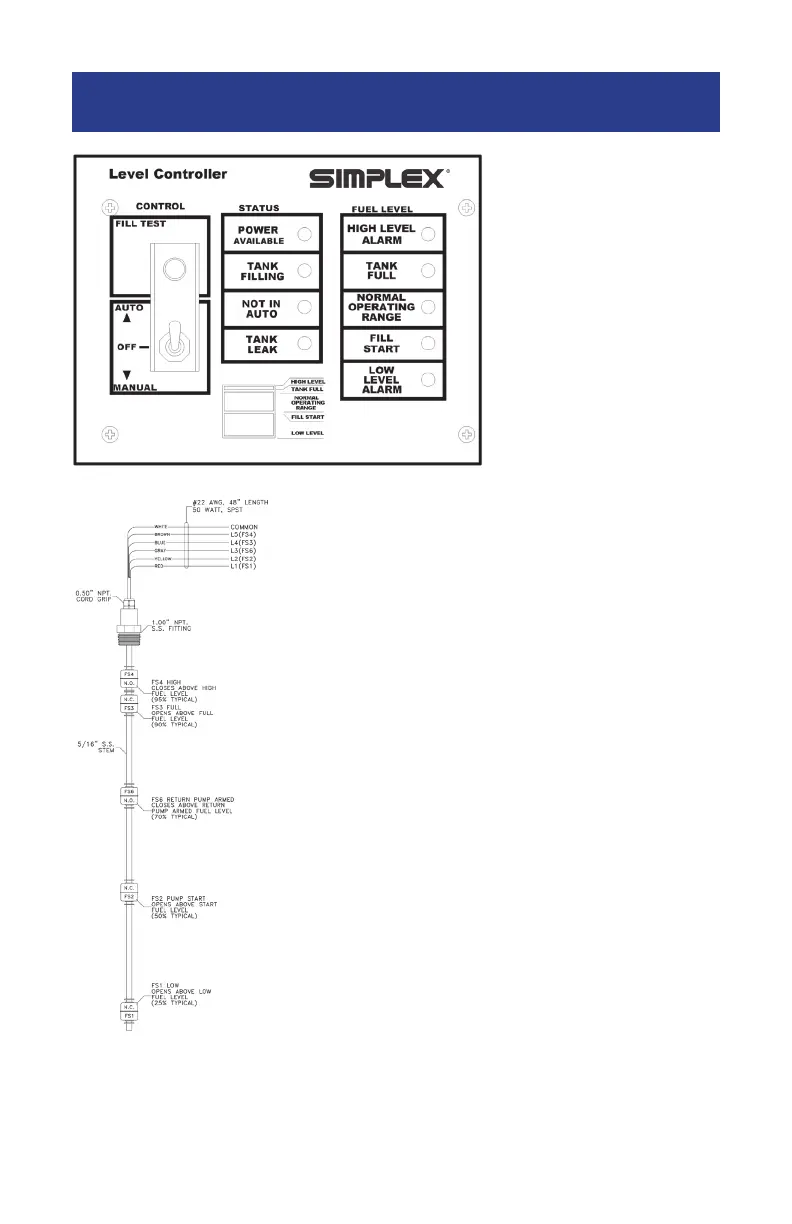

e prime controller in the Day Tank is the printed

circuit board. e Day Tank printed circuit board

is powered by a fused internal 24VDC, 2A, power

supply. e printed circuit board utilizes 24VDC

components to analyze the fuel level data it receives

from the four Day Tank fuel level sensors. e four

fuel level sensors together with the sensor mount-

ing plate comprise the fuel level sensor assembly.

When 120VAC, single phase, 60Hz control power is

supplied to the Day Tank control system the Power

Available L.E.D. is illuminated. See Parts Legend

Drawing for specic components used.

During automatic operation, the printed circuit

board energizes and de-energizes control relays,

the motor starter contactor, and the pump/motor to

automatically rell the Day Tank as fuel is consumed

Loading...

Loading...